Aluminum material, method of manufacturing aluminum material , electrolytic capacitor and anode material

A technology for electrolytic capacitors and aluminum materials, applied in electrolytic capacitors, capacitors, anodizing and other directions, can solve the problems of difficult to uniformly remove the surface layer, difficult to etch characteristics of aluminum materials, and to increase capacitance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1-1

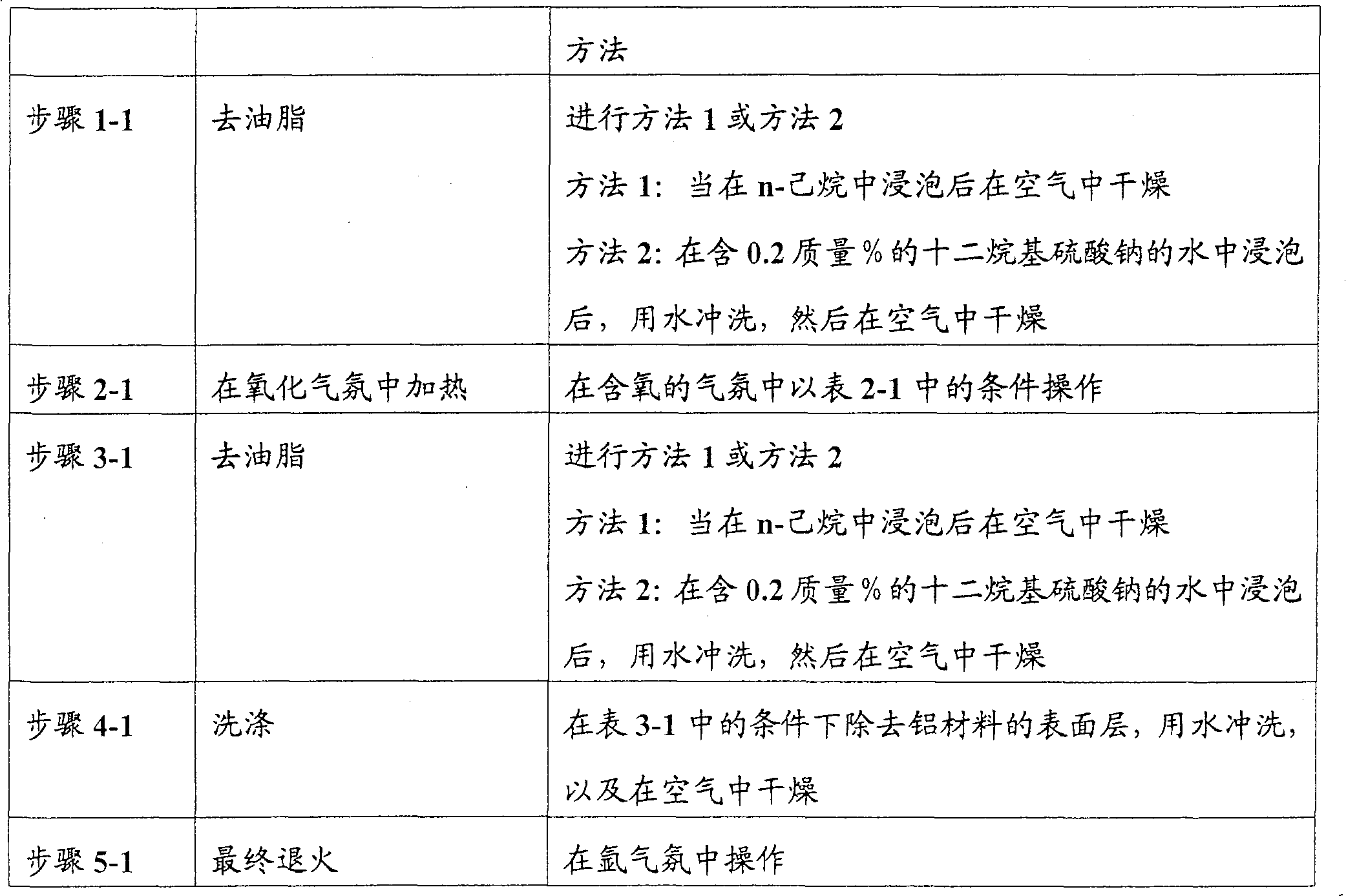

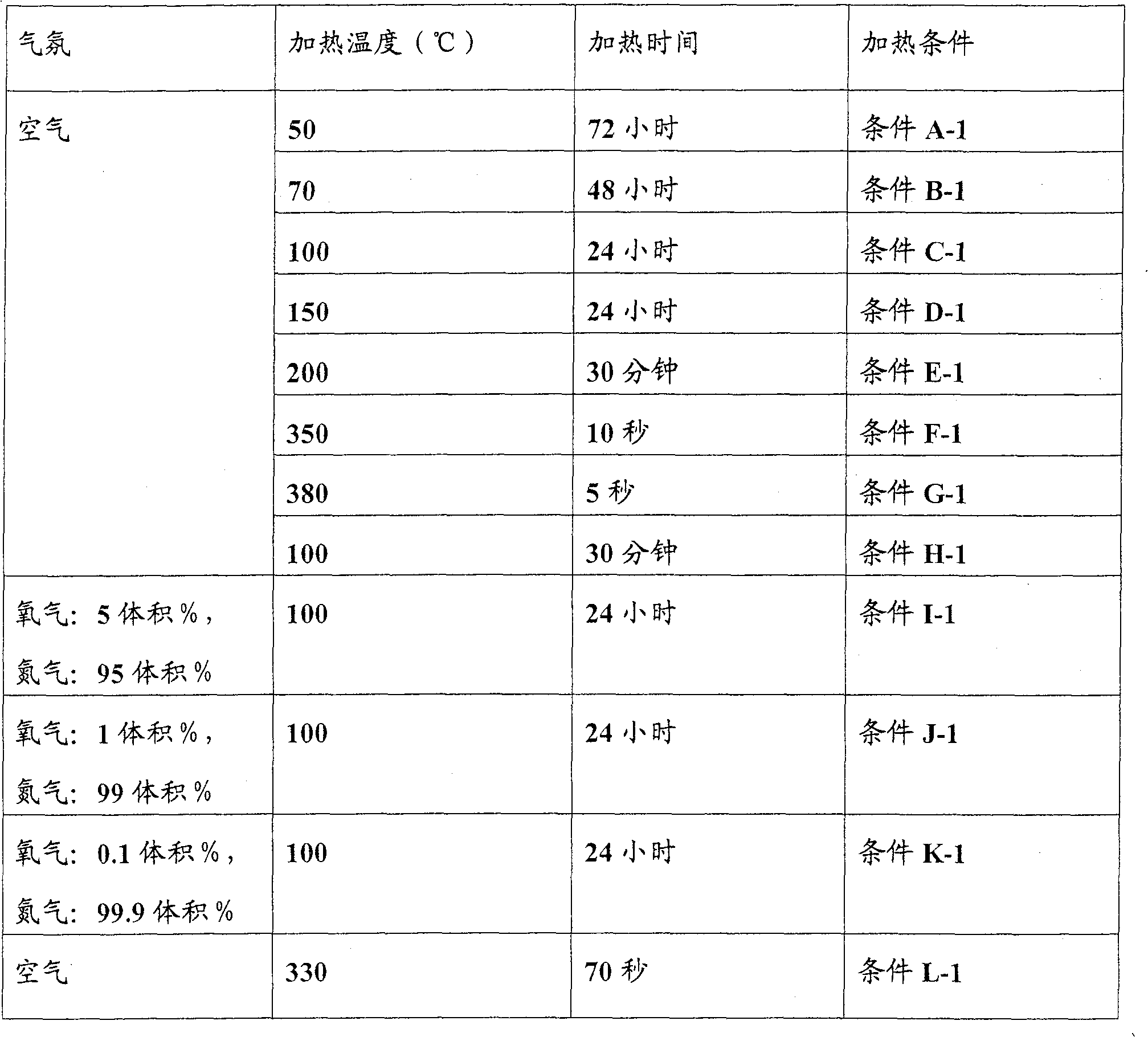

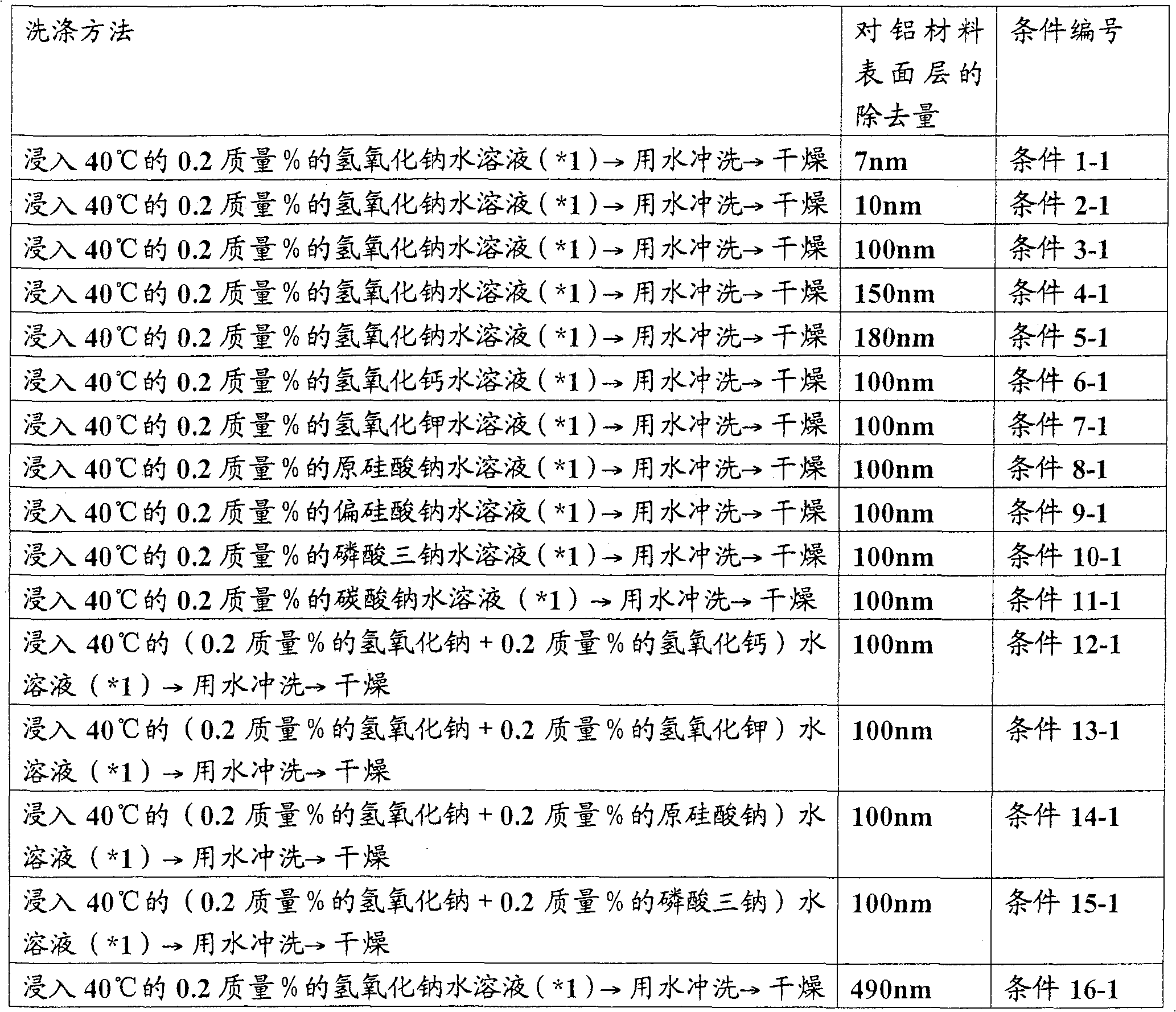

[0360] The aluminum block is subjected to hot rolling, cold rolling, intermediate annealing and finish cold rolling in sequence. As shown in Table 5-1, the obtained flake aluminum material having a thickness of 110 μm and a purity of 99.99% was degreased using n-hexane (step 1-1). After heating at 150° C. in air for 24 hours (step 2-1), by immersing in 20% by mass sulfuric acid solution at 80° C., an average 10 nm surface layer of the aluminum material was removed (step 4-1). Then, the material was subjected to final annealing (step 5-1) at 540° C. for 4 hours in an argon atmosphere to obtain an aluminum material for an electrode of an electrolytic capacitor.

example 2-1 to example 49-1

[0361] Example 2-1 to Example 49-1, Comparative Example 1-1 to Comparative Example 3-1

[0362] Under the conditions shown in Tables 5-1 to 7-1, aluminum materials for electrolytic capacitor electrodes were obtained.

[0363] The aluminum material obtained in each example and comparative example was immersed in HCL containing 1.0 mol / liter and 3.5 mol / liter H 2 SO 4 in an aqueous solution, wherein the temperature of the solution is 75°C. At the same temperature, using solutions with the same composition, at 0.2A / cm 2 The current density is applied to the material for direct current electrode etching.

[0364] The electrolytically treated aluminum material was further immersed in a mixed solution of 90° C. hydrochloric acid-sulfuric acid having the same composition for 360 seconds, and then an etched foil with larger diameter pits was obtained. The obtained etched foil was dielectrically formed by anodizing at a forming voltage of 270 V according to EIAJ standards, thereby ...

example 1-2

[0434] The aluminum ingots in Table 1-2 having 0.0015 mass % Fe, 0.0022 mass % Si, and 0.0055 mass % Cu (composition 3-2) were hot rolled. Aluminum materials having a thickness of 130 µm obtained by processing the plates obtained by cold rolling under the conditions shown in Table 6-2. That is, intermediate annealing (step 2-2) was applied at 260° C. for 18 hours in air. Then, finish cold rolling with a reduction of 20% was performed (step 5-2). After finish cold rolling, degrease the aluminum material with n-hexane (step 6-2), and then remove the 12nm surface layer of the aluminum material by immersing in 20% by mass phosphoric acid aqueous solution at 80°C (step 7-2). Then, the aluminum material was subjected to final annealing at 530° C. for 6 hours in an argon atmosphere (step 8-2) to obtain an aluminum material for an electrode of an electrolytic capacitor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com