Medium temperature proton conductive mateiral basedon hydrophilic carbon nano tube and its preparing method

A technology of carbon nanotubes and proton conduction, applied in the fields of polymer materials and electrochemistry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

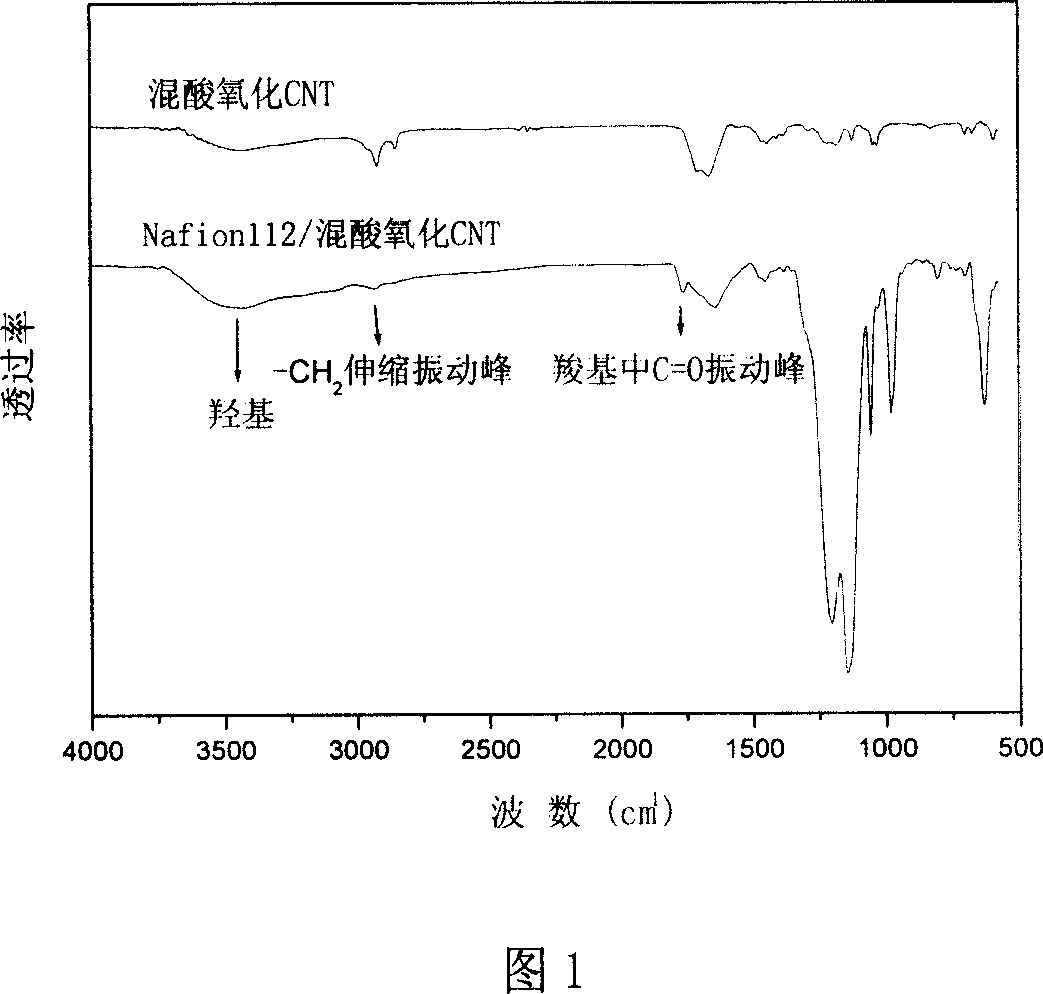

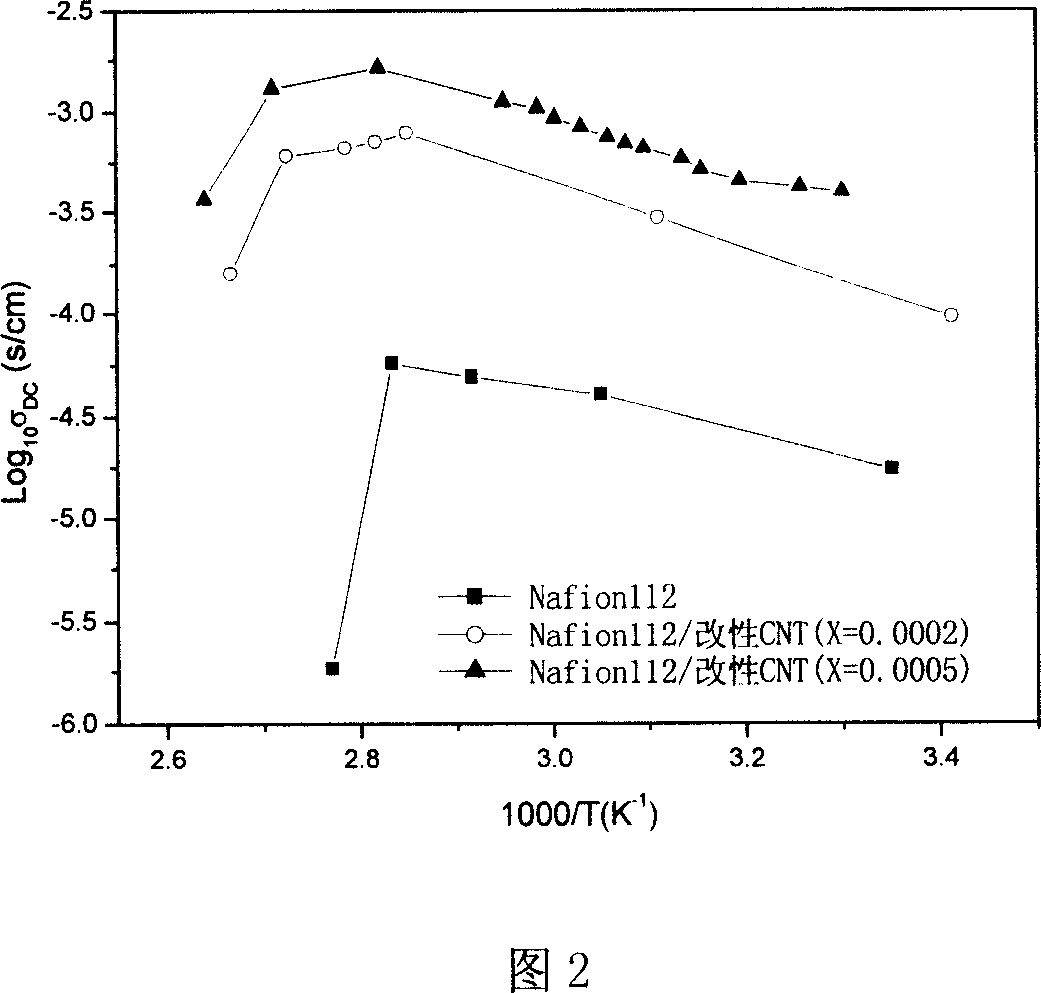

[0024] Preparation of aqueous dispersion of carbon nanotubes oxidized by mixed acid: ultrasonically treat carbon nanotubes in concentrated sulfuric acid / concentrated nitric acid with a volume ratio of 3:1 for 30 minutes, reflux and condense at 100°C for 4 hours, and vacuum the carbon nanotubes with a cellulose membrane with a pore size of 0.22 μm. Suction filter, wash with deionized water until neutral, scrape it into a small bottle with a horn spoon, add water to make an aqueous dispersion. Take a clean glass plate and weigh W 1 , drop 1ml of carbon nanotube aqueous dispersion on it, dry, weigh W 2 , (W 2 -W 1 ) / 1 to obtain the concentration (g / ml) of the carbon nanotube aqueous dispersion.

[0025] Preparation of Nafion 112 solution: Dissolve Nafion 112 resin in N,N-dimethylformamide, dissolve for 1 hour at 180°C under nitrogen protection, and make it fully dissolved to make a 5% solution.

[0026] Preparation of composite membrane:

[0027] The ratio of raw materials u...

Embodiment 2

[0034] Preparation of aqueous dispersion of mixed acid oxidized carbon nanotubes: ultrasonically treat carbon nanotubes in concentrated sulfuric acid / concentrated nitric acid with a volume ratio of 3.2:1 for 35 minutes, reflux and condense at 110°C for 6 hours, and vacuum the carbon nanotubes with a cellulose membrane with a pore size of 0.22 μm. Suction filter, wash with deionized water until neutral, scrape it into a small bottle with a horn spoon, add water to make an aqueous dispersion. Take a clean glass plate and weigh W 1 , drop 1ml of carbon nanotube aqueous dispersion on it, dry, weigh W 2 , (W 2 -W 1 ) / 1 to obtain the concentration (g / ml) of the carbon nanotube aqueous dispersion.

[0035] Preparation of sPBI solution: sPBI was dissolved in a certain amount of 1-methyl-2-pyrrolidone, and dissolved at 60° C. for 2 hours to fully dissolve.

[0036] Preparation of composite membrane:

[0037] The ratio of raw materials used is as follows:

[0038] Mixed acid oxidi...

Embodiment 3

[0043] Preparation of surface carboxylated carbon nanotube aqueous dispersion: ultrasonically treat carbon nanotubes in concentrated sulfuric acid / concentrated nitric acid with a volume ratio of 3:1 for 30 minutes, reflux condensation at 100°C for 4 hours, and use cellulose with a pore size of 0.22 μm Membrane vacuum filtration, washed with deionized water until neutral, scraped into a small bottle with a horn spoon, added water to make a water dispersion.

[0044] Take a clean glass plate and weigh W 1 , drop 1ml of carbon nanotube aqueous dispersion on it, dry, weigh W 2 , (W 2 -W 1 ) / 1 to obtain the concentration (g / ml) of the carbon nanotube aqueous dispersion.

[0045] Take 30 mg of carbon nanotubes that have been oxidized by the above mixed acid, disperse them in 50 ml of DMF (N, N-dimethylformamide), treat them ultrasonically for 30 min., add 2 g of azobisisobutyronitrile, and blow nitrogen at room temperature to remove oxygen for 25 min. Minutes, 70 ° C magnetic st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com