Extraction method for primary active matter of edible fungi

An extraction method and technology for active substances, which are applied in the field of preparation of edible fungus extracts, can solve the problems of loss of active ingredients, complexation, hydrolysis, oxidation, reduction, combustion, etc., and achieve the effects of reducing volatilization and avoiding interference and harm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

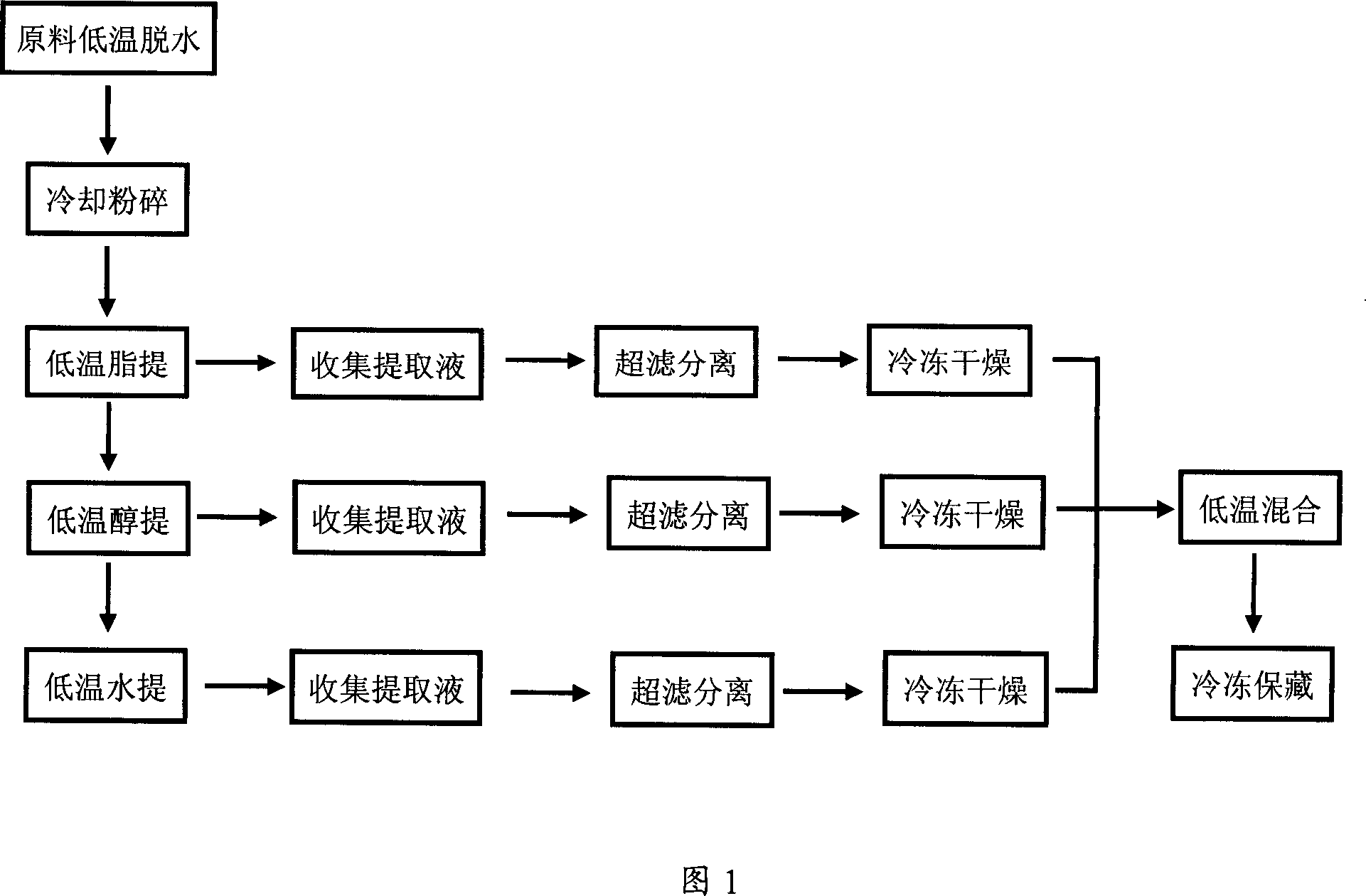

Method used

Image

Examples

Embodiment 1

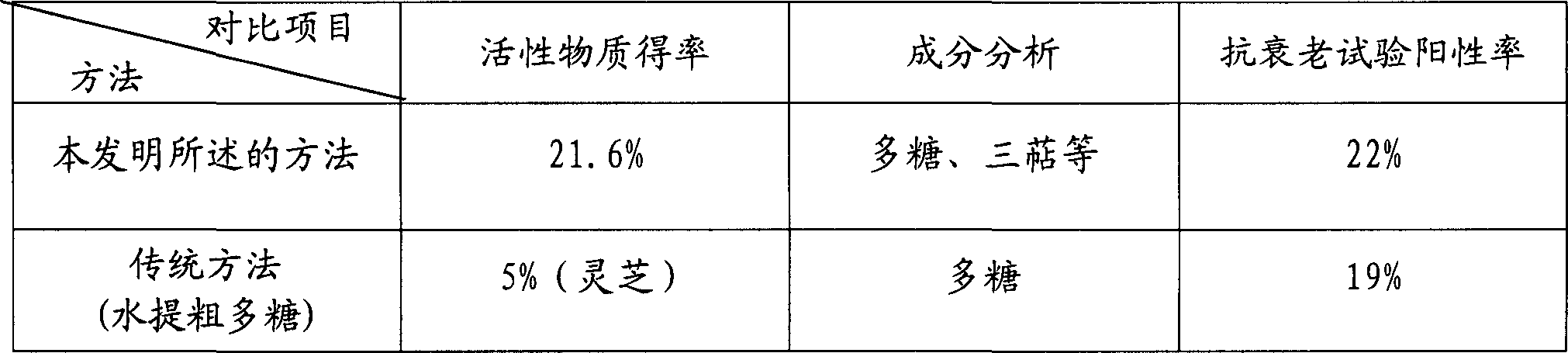

[0031] 1. Extraction of the active components of Ganoderma lucidum

[0032] In an air-conditioned workshop at 18°C, add 1 kg of whole Ganoderma lucidum (Ganoderma lucidum processed product, powder) (produced by Guangdong Yuewei Edible Fungi Technology Co., Ltd.) into 3L of petroleum ether, soak in an ultrasonic washing tank for 1 hour, filter, and add 1L of petroleum ether to the filter residue Filter after soaking, repeat the operation once, combine the filtrate and concentrate with ultrafiltration equipment to obtain a concentrated solution, and the product (A) after the concentrated solution is dried by a freeze dryer is temporarily stored in a drying dish. After the filter residue was dried in the shade for 1 hour, add 3L of 95% ethanol and soak it in an ultrasonic washing tank for 2 hours, filter, add 1L of ethanol to the filter residue twice for soaking and then filter, combine the filtrate and concentrate it with ultrafiltration equipment to obtain a concentrated solutio...

Embodiment 2

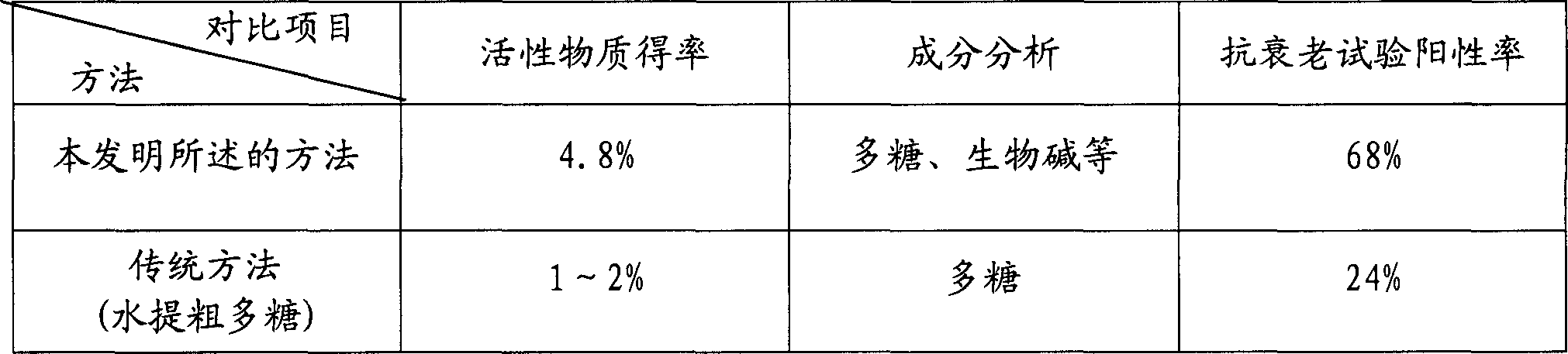

[0038] 1. Extraction of active components of Versicolor versicolor

[0039] The dried fruiting body (mushroom body) of Yunzhi was pulverized at 18°C with a water-cooled low-temperature pulverizer equipped with a 40-mesh sieve. In an air-conditioned workshop at 18°C, add 1 kg of Versicolor versicolor fruiting body powder to 1.5 L of petroleum ether and immerse in an ultrasonic washing tank for 1 hour, filter, and filter the filter residue after soaking with 1 L of petroleum ether, repeat the operation once, and combine the filtrates with ultrafiltration The equipment is concentrated to obtain a concentrated solution, and the product (A) after the concentrated solution is dried by a freeze dryer is temporarily stored in a drying dish. After the filter residue was dried in the shade for 1 hour, add 1.5L 95% ethanol and immerse in the ultrasonic washing tank for 2 hours, filter, add 1L ethanol to the filter residue twice and then filter, combine the filtrate and concentrate it w...

Embodiment 3

[0045] 1. Extraction of Active Components of Lentinus edodes

[0046]Fresh shiitake mushrooms were dehydrated in quick-freezing equipment for 6 hours, and the fruiting bodies (mushroom bodies) of shiitake mushrooms were pulverized at 18°C with a water-cooled low-temperature pulverizer equipped with a 20-mesh sieve. In an air-conditioned workshop at 18°C, add 1kg of shiitake fruiting powder to 2L of petroleum ether, soak in an ultrasonic washing tank for 1 hour, filter, add 1L of petroleum ether to the filter residue twice and then filter, combine the filtrate and concentrate it with ultrafiltration equipment A concentrated solution is obtained, and the product (A) after the concentrated solution is dried by a freeze dryer is temporarily stored in a drying dish. After the filter residue was dried in the shade for 1 hour, add 2L of 95% ethanol and immerse in an ultrasonic washing tank for 2 hours, filter, add 1L of ethanol to the filter residue twice for immersion and then fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com