Mixed solvent for preparing neoprene adhesive

A technology of mixing solvents and solvent oils, applied in the direction of chloroprene adhesives, adhesives, adhesive types, etc., can solve the problems of uncommon use of solvents, high production costs, and high prices, and achieve excellent environmental protection and low odor , low toxicity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: get 100 parts of 130# solvent naphtha, 40 parts of dimethyl carbonate, 33 parts of butyl acetate, 22 parts of methylcyclohexane, 27 parts of butanone and mix and stir evenly, obtain clear and transparent colorless solvent, product Small odor, low toxicity, excellent environmental protection, good solubility to chloroprene rubber, no adverse effect on the synthesis process of chloroprene rubber, the conversion rate of MMA monomer after grafting reaction with MMA is 41%, and the initial tensile strength of the obtained product is Up to 3.4KN / m.

Embodiment 2~6

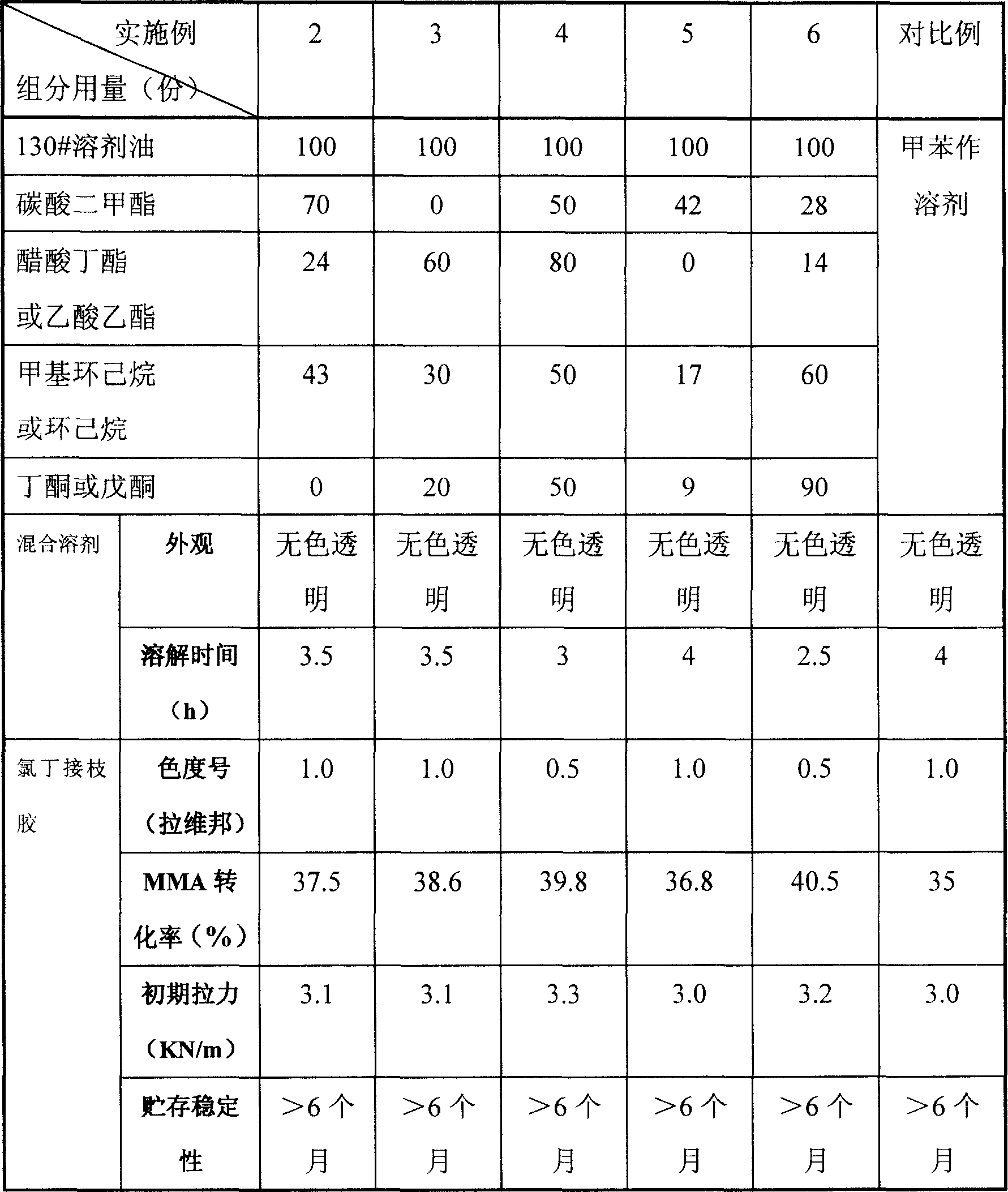

[0018] Embodiment 2~6: preparation method is the same as embodiment 1, 100 parts of 130# solvent naphthas, change the content of dimethyl carbonate, butyl acetate, ethyl acetate, methylcyclohexane, cyclohexane, butanone, pentanone Consumption, the results are as follows in Table 1:

[0019] Table 1: The effect of mixed solvents with different ratios

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com