Process for preparing pretreatment layer and coating on magnesium and magnesium alloy surface

A surface pretreatment, magnesium alloy technology, applied in the direction of superimposed layer plating, metal material coating process, coating, etc., can solve the problems of poor bonding force of magnesium alloy matrix, many steps, difficult to realize, etc., to improve processing Accuracy, improvement of corrosion resistance, effect of simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

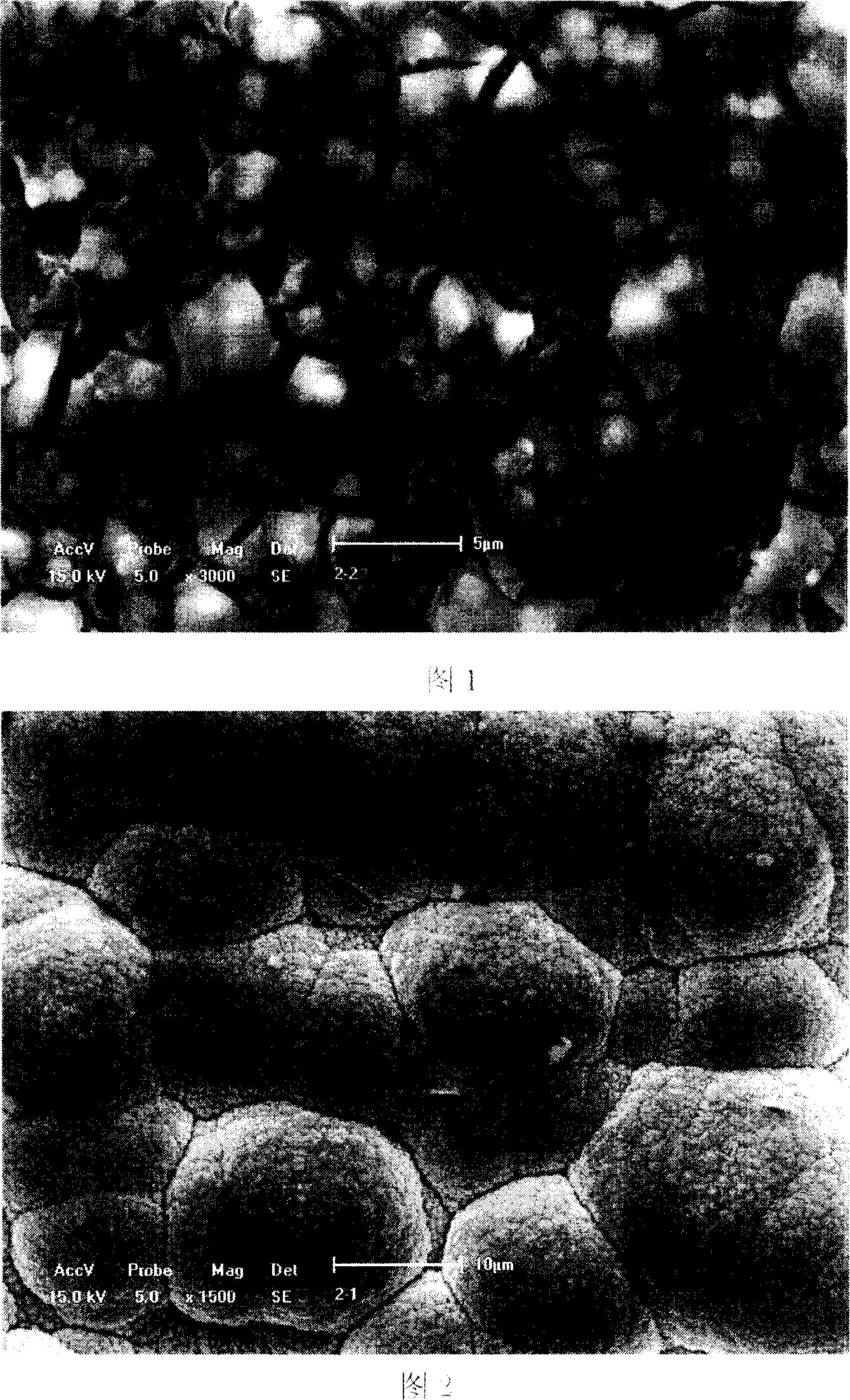

Image

Examples

Embodiment 1

[0032] The magnesium alloy material is an AZ31 type plate, which is cut into a 1.5cm×2.5cm rectangular sample, and polished with 240, 500, 1000, and 1500 sandpaper in sequence.

[0033] (1) Ultrasonic degreasing

[0034] Ultrasonic degreasing with acetone or trichlorethylene organic solvent, operating temperature: room temperature, operating time: 10min.

[0035] (2) Alkali washing, solution preparation and operating conditions are as follows:

[0036] NaOH 50g / L, NaOH 3 PO 4 12H 2 O 10g / L, temperature 55-65°C, time 8-10 minutes.

[0037] (3) Preparation of metal replacement membrane, solution preparation and operating conditions are as follows:

[0038] CoSO 4 ·7H 2 O 2g / L, trisodium citrate 2.1g / L, pH value 5.5±0.2, temperature 20°C, time 15min.

[0039] (4) Chemical plating solution formula:

[0040] NiSO 4 ·6H 2 O 18g·L -1 , C 6 h 8 o 7 ·H 2 O 12g·L -1 , HF (40%) 10ml·L -1 , NH 4 HF 2 20g·L -1 , NaH 2 PO 2 ·H 2 O22g L -1 , Thiourea 1mg·L -1, pH v...

Embodiment 2

[0044] Grinding, ultrasonic degreasing, and alkali cleaning are the same as in Example 1. The difference from Example 1 lies in the preparation of the metal replacement membrane, solution preparation and operating conditions are as follows:

[0045] CoSO 4 ·7H 2 O 5g / L, sodium dodecylsulfonate 80mg / L, trisodium citrate 5.3g / L, pH value 6±0.2, temperature 20°C, time 15min.

[0046] Then carry out according to the (4) step in embodiment 1.

[0047] Wash in deionized water between steps.

[0048] The magnesium alloy sample of the coating obtained in this embodiment is subjected to thermal shock and file tests, and meets the requirements of the national standard GB / T13913-92.

Embodiment 3

[0050] Grinding, ultrasonic degreasing, and alkali cleaning are the same as in Example 1. The difference from Example 1 lies in the preparation of the metal replacement membrane, solution preparation and operating conditions are as follows:

[0051] CoSO 4 ·7H 2 O 8g / L, sodium dodecylsulfonate 80mg / L, trisodium citrate 8.5g / L, pH value 6.5±0.2, temperature 20°C, time 15min.

[0052] Then carry out according to the (4) step in embodiment 1.

[0053] Wash in deionized water between steps.

[0054] The magnesium alloy sample of the coating obtained in this embodiment is subjected to thermal shock and file tests, and meets the requirements of the national standard GB / T13913-92.

[0055] The following examples are the preparation methods of the single metal film Cu and the coating.

PUM

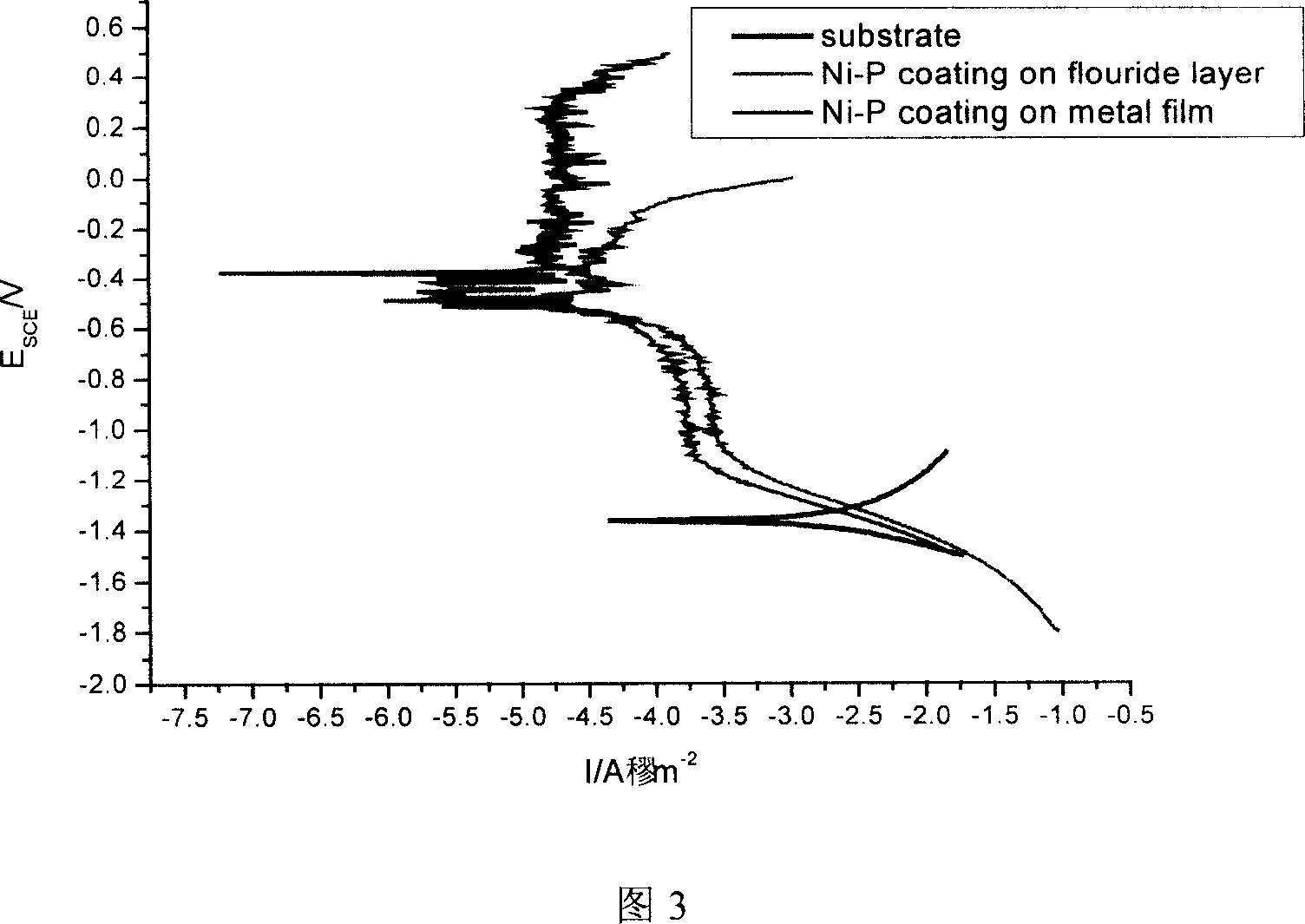

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com