Method and device for drying painted vehicle bodies

A kind of equipment and drying technology, applied in the direction of body drying, lighting and heating equipment, drying solid materials, etc., can solve the problem of gas atmosphere escape and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

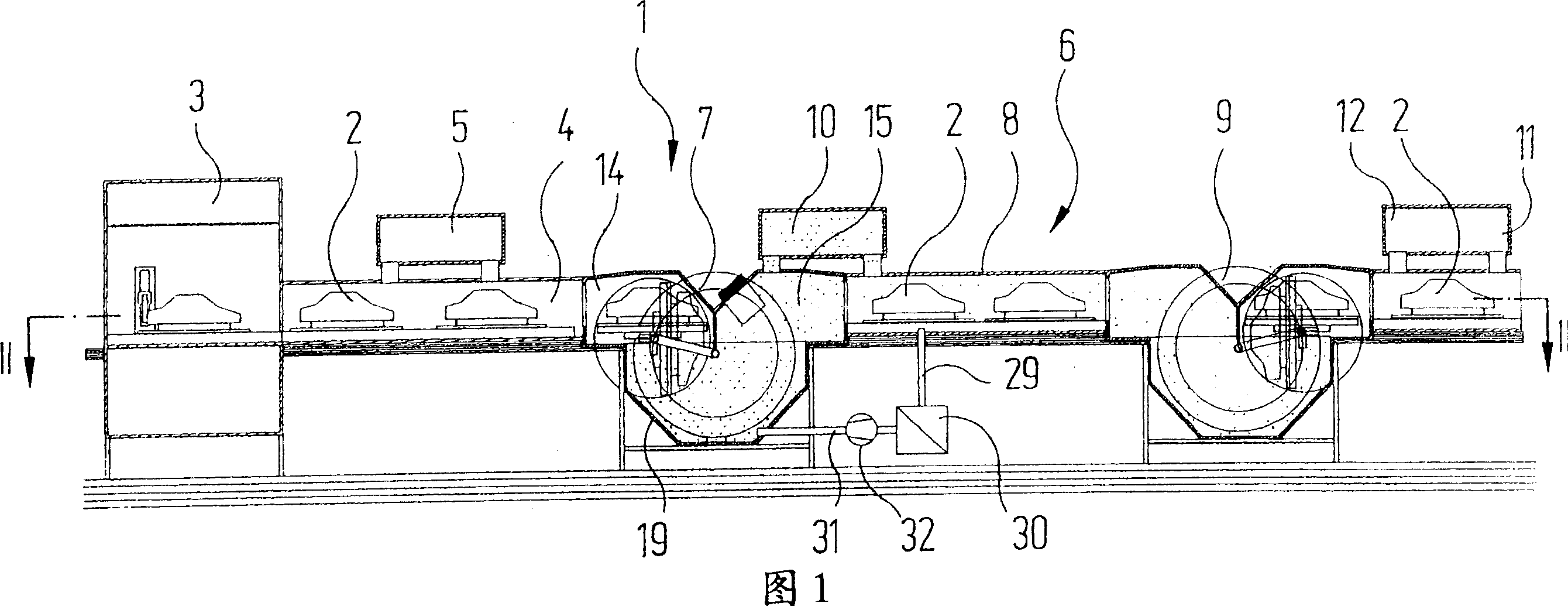

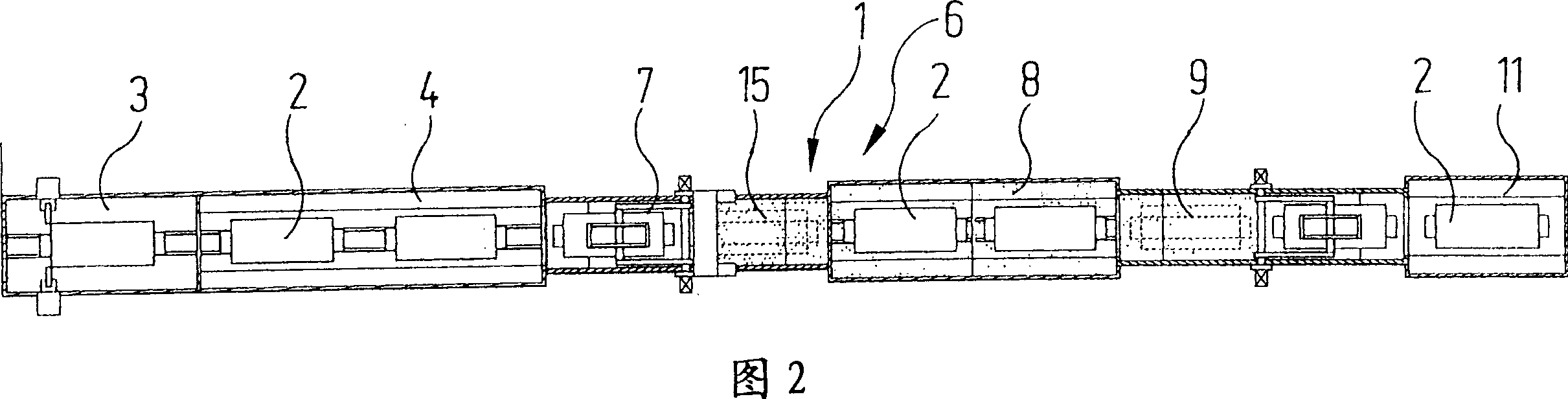

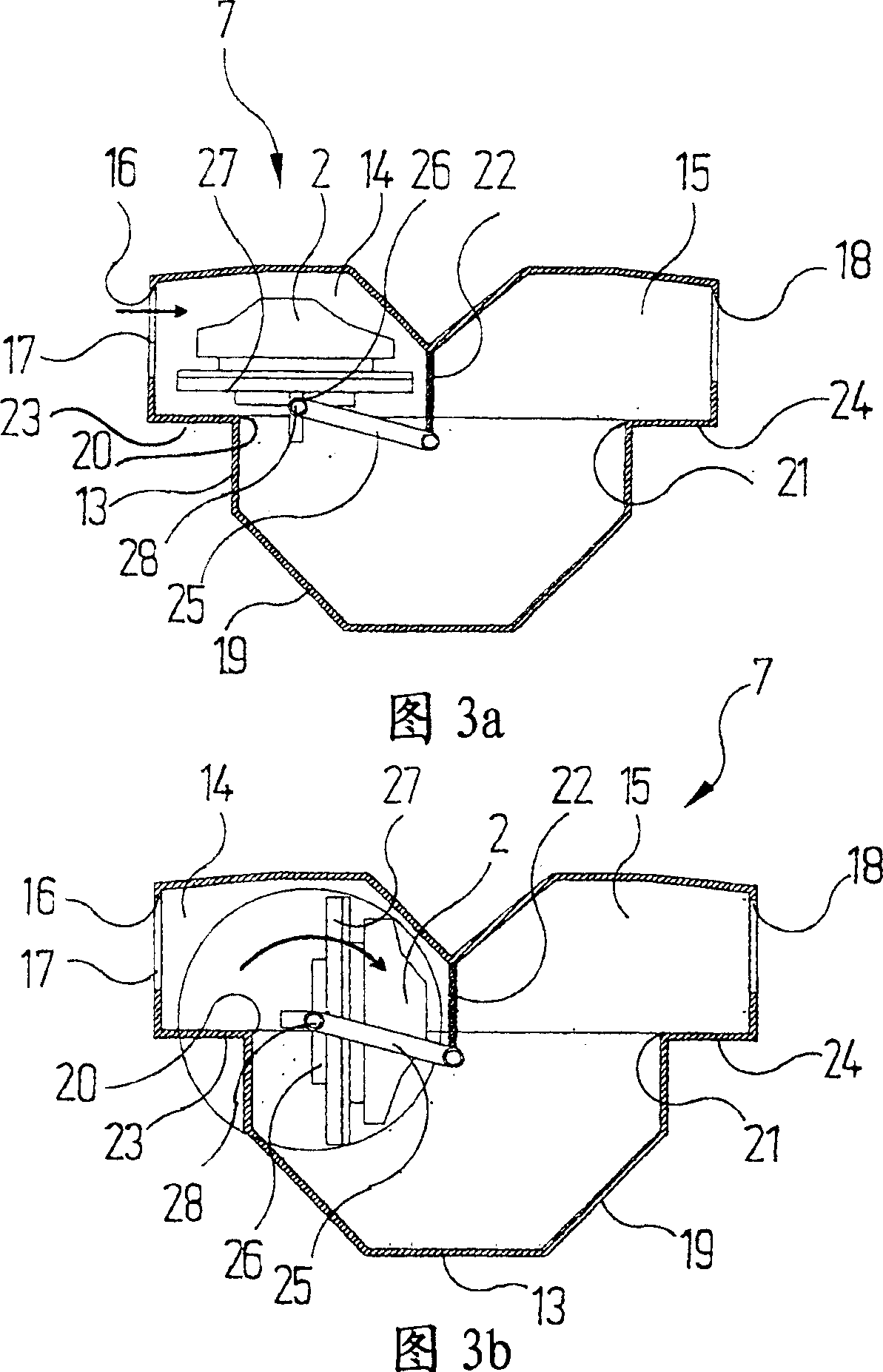

[0040] Referring first to Figures 1 and 2, a portion of a painting installation is indicated generally by the reference numeral 1 therein. The painting installation 1 is used for painting a vehicle body 2 ; various processing stations, not shown, are connected in a known manner before or after the part shown. A vehicle body 2 passes through the painting installation 1 from left to right in FIGS. 1 and 2 . The vehicle body first enters the painting booth 3 in which the vehicle body is coated with paint in a known manner. The exact design of the spray booth 3 and the way in which the paint is applied are not critical in the context of the present invention.

[0041] The vehicle body 2 emerges from the painting booth 3 and first passes into a pre-drying device 4 , the design of which is also not relevant in detail and is known to the skilled person. In the pre-drying device 4, the volatilization / evaporation of the solvent takes place at a temperature between 40 and 150°C. For ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com