NbTiAl series laminate structure intermetallic compound composite material and its preparation method

A technology of intermetallic compounds and composite materials, which is applied in the field of intermetallic compound-based composite materials, and can solve problems such as difficulty in flexible change of lamination thickness and layer thickness ratio, weak interlayer bonding strength, low room temperature yield strength and fracture toughness , achieve great design flexibility, high bonding strength between layers, solve the effects of low temperature brittleness and high temperature strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In the intermetallic composite material of the present invention, the Nb-based intermetallic compound is Nb with the A15 structure containing the NbTiAl composition. 3 Al-based intermetallic compounds, especially intermetallic compounds containing Nb12Ti22Al, also including Nb with 15 structure containing NbAl components 3 Al intermetallic compound;

[0023] The ductile metal alloy in the intermetallic composite material of the present invention is mainly a niobium-titanium solid solution alloy with a β / B2 structure, especially an Nb40Ti15Al alloy;

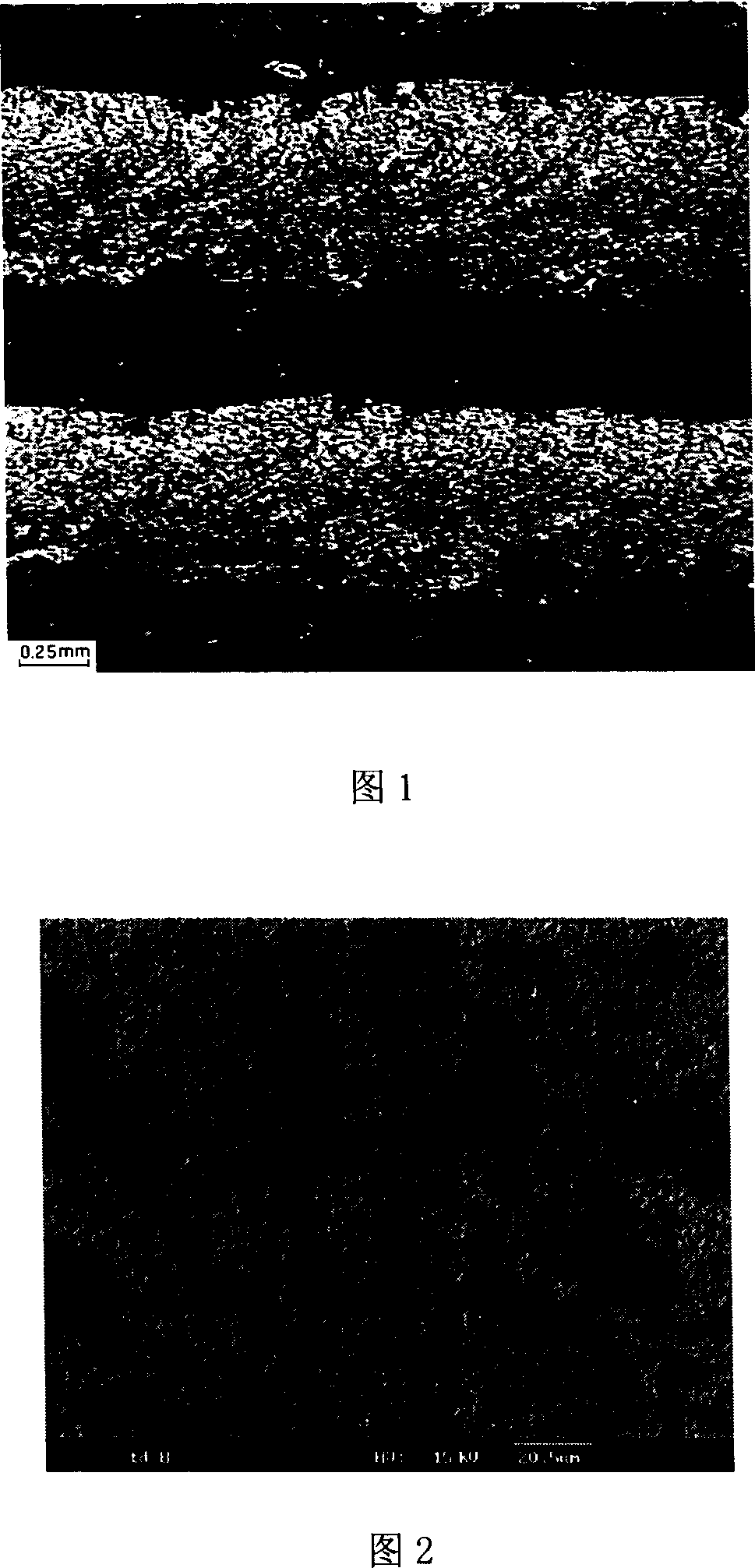

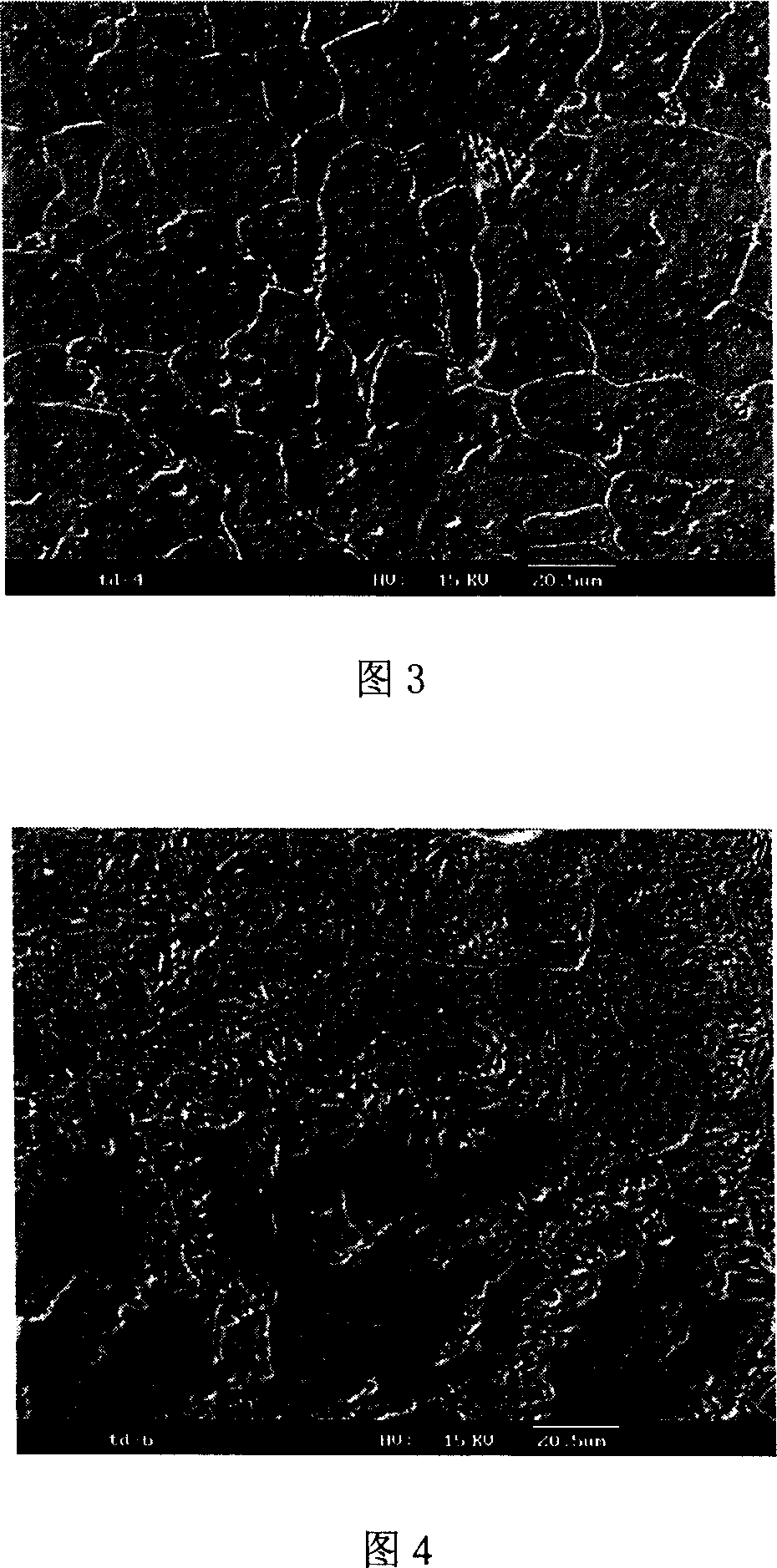

[0024] Figure 1 shows the laminated structure Nb 3 The macrostructure of the Al / NbTiAl intermetallic compound composite material, which is composed of a layer of NbTiAl tough alloy layer with β / B2 structure (dark layer in Figure 1, microstructure as shown in Figure 3) superimposed with a layer of brittle A15 structure Nb 3 Al intermetallic compound layer (light-colored layer in Figure 1, microstructure as shown in Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com