Method and device for preparing Shanxi mellow vinegar by liquid-solid technology

A technology of thinning before solidifying and aging mature vinegar, which is applied in the preparation of vinegar, etc., can solve the problems of high labor intensity, low work efficiency and low efficiency of workers, shorten the time of wine fermentation, improve work efficiency and shorten the process time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

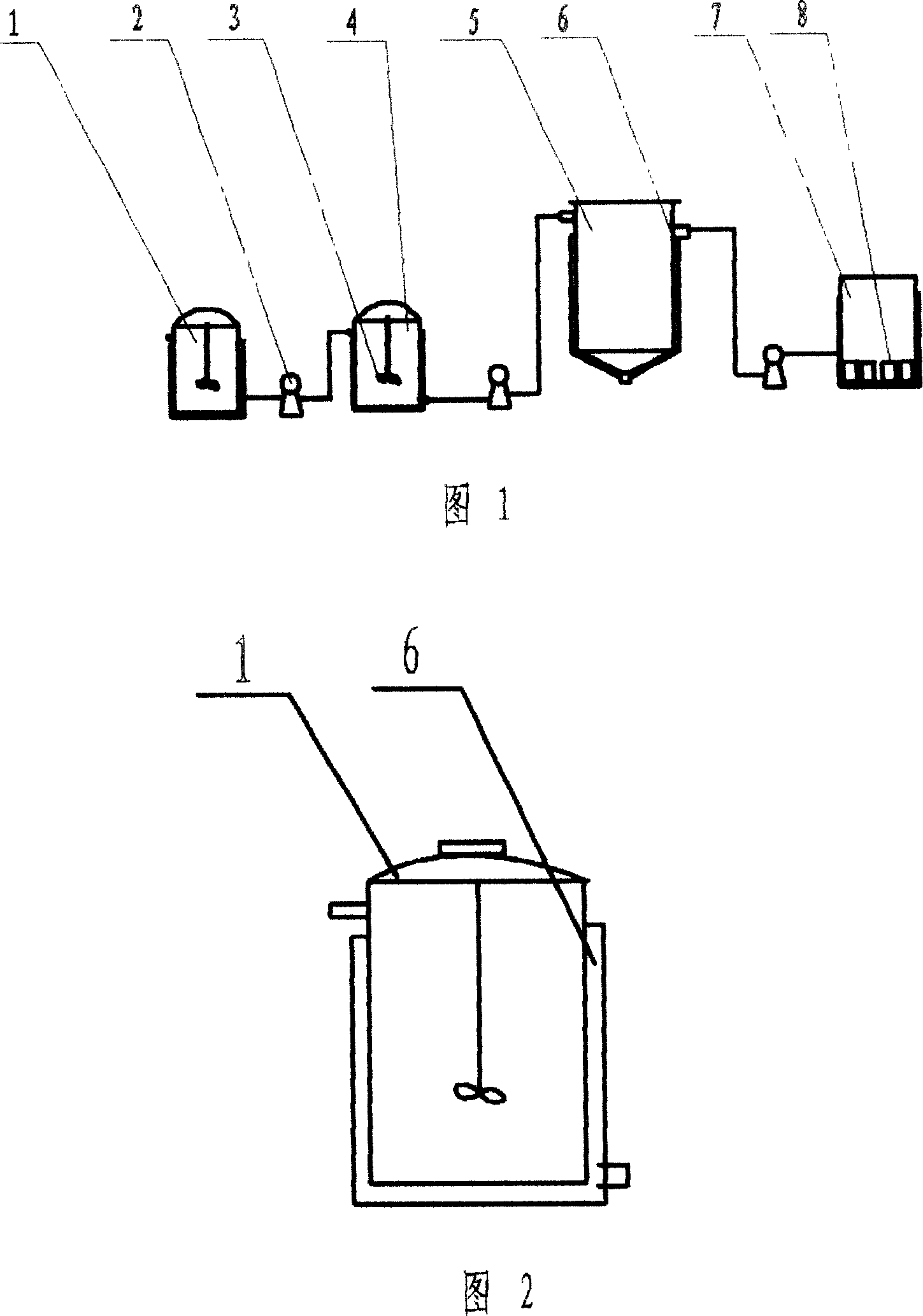

[0041] Embodiment 1 Get 30 kilograms of sorghum and 25 kilograms of corn, peel and pulverize and cross 40 mesh sieves to get 50 kilograms of powder, put the gained powder into the moistening tank and add 40-45 kilograms of water, moisten the material for 8-10 hours. Add about 150 kg of water to the obtained wet material and stir evenly, pump it into the liquefaction tank 1 and heat it to 100-110° C., add 25 ml of amylase with a content of 100,000 enzyme units into the tank and stir. After boiling for about 1.5-2 hours, the liquefied material is poured into the saccharification tank 4 by the liquid pump 2, and circulating cold water is added to the temperature-adjusting interlayer of the saccharification tank 4 to cool the liquefied material to 55-65°C and keep it warm. 80ml of glucoamylase with a content of 100,000 enzyme units and 15kg of bran were stirred at the same time. After 3-4 hours of saccharification, a saccharification liquid is obtained. Measure wherein reducing s...

Embodiment 7

[0044] Example 7 Annual production of 30,000 tons of Shanxi mature vinegar, 10 liquefaction tanks with a diameter of 1.5 meters and a height of 2.3 meters. The temperature-regulating interlayer is 8 cm. The diameter of the mash tank is 1.5 meters, the height is 2.3 meters, and the number is 10. The wine tanks are 1.5 meters in diameter, 2.5 meters high, and 80 in number. The immobilized yeast saccharification tank has a diameter of 1.1 meters and a height of 1.1 meters.

[0045] implement

[0046] Other parameters are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com