Synchronous gas-liquid purifying high voltage DC/pulse discharge method and device

A high-voltage direct current, pulse discharge technology, applied in chemical instruments and methods, electrical components, separation methods, etc., can solve the problem of reasonable matching between the design structure of the plasma generator and the power supply, and the simultaneous degradation and removal of few gas-liquid two-phase pollutants , high power supply costs and other issues, to achieve the effect of low energy consumption and operating costs, no secondary pollution, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

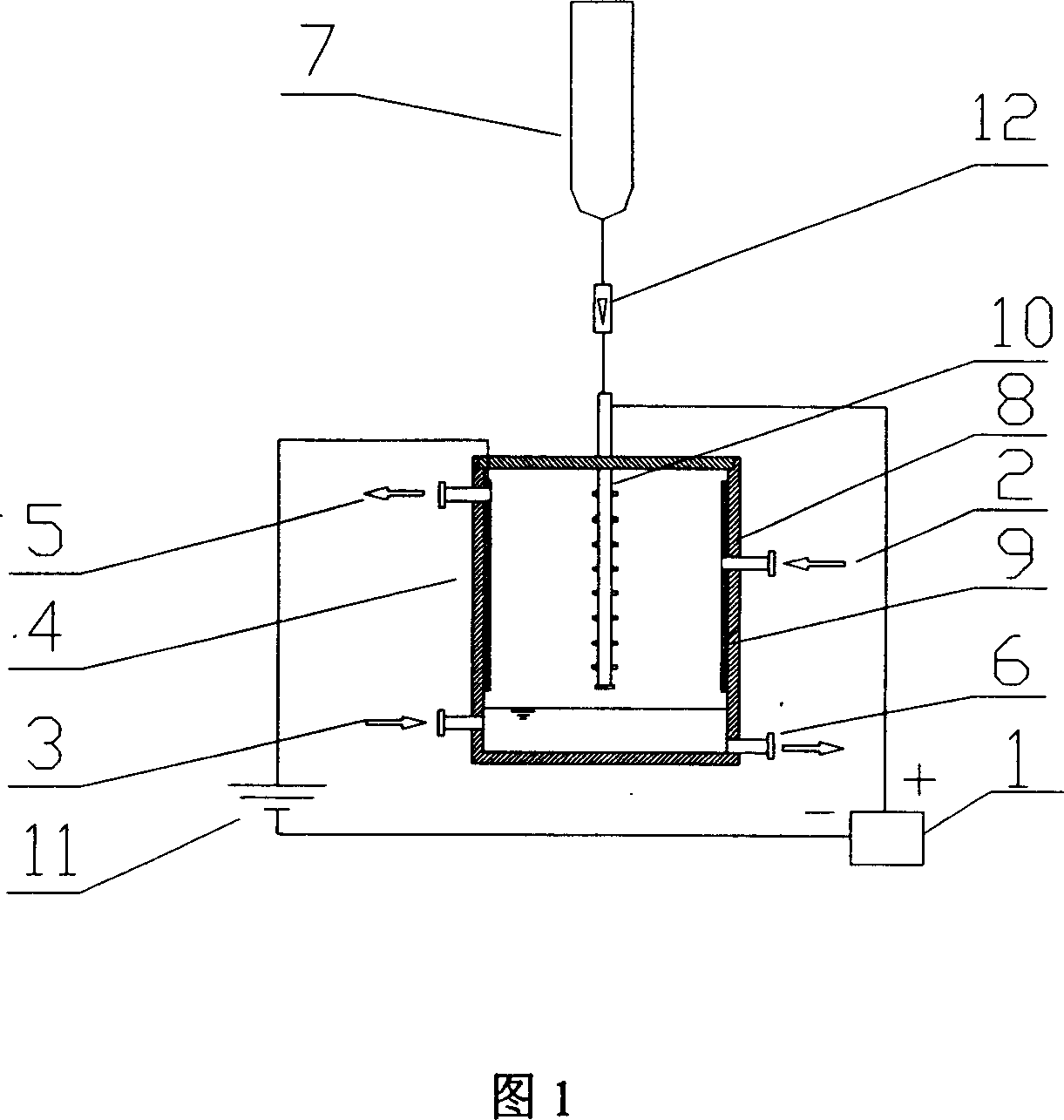

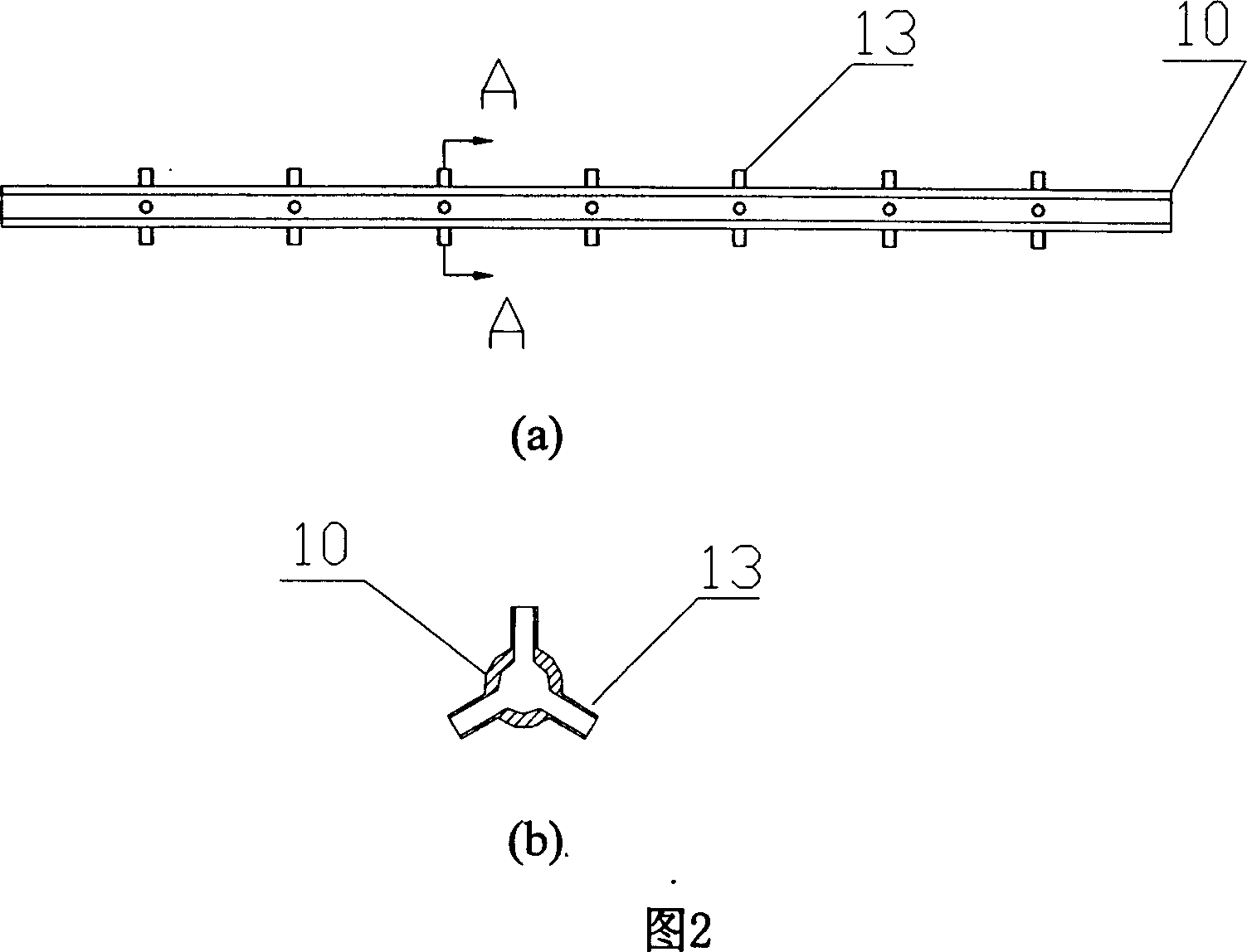

[0030] As shown in Figure 1, a high-voltage direct current / pulse discharge device for synchronously purifying gas and liquid: it includes a high-voltage direct current / pulse power supply 1, which is sequentially opened with an air outlet 5, an air inlet 2, a liquid inlet 3, and an outlet from top to bottom. The plasma generator 4 composed of the cylindrical insulating shell 8 of the liquid port 6, the cylindrical metal mesh grounding electrode 9 and the corona electrode 10 of the hollow nozzle; The corona electrode 10 is installed in the center of the cylindrical metal mesh ground electrode 9 and fixed on the upper cover of the plasma generator 4. The bottom of the hollow nozzle corona electrode 10 is located on the same level as the cylindrical metal mesh ground electrode 9. Parallel to the gas-liquid interface, the hollow nozzle corona electrode 10 is connected to the positive pole of the high-voltage DC / pulse power supply 1 . As shown in Figure 2, the hollow nozzle corona p...

Embodiment 2

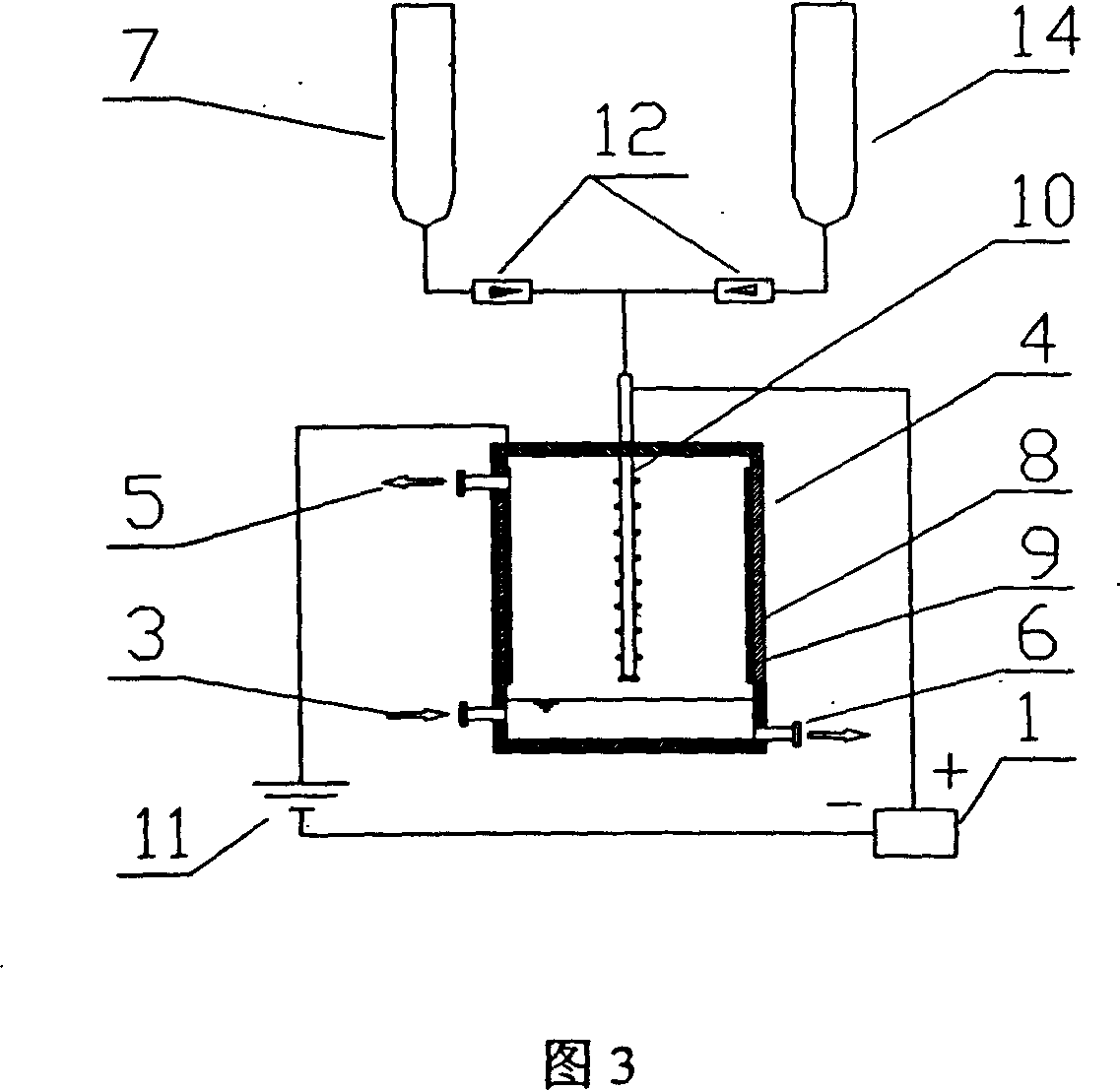

[0033] As shown in Figure 3, a high-voltage direct current / pulse discharge device for synchronously purifying gas and liquid: including a high-voltage direct current / pulse power supply 1, a cylinder with a gas outlet 5, a liquid inlet 3, and a liquid outlet 6 sequentially opened from top to bottom The plasma generator 4 is composed of a shape insulating shell 8, a cylindrical metal mesh ground electrode 9 and a hollow nozzle corona electrode 10. The inner wall of the cylindrical insulating shell 8 is equipped with a cylindrical metal mesh grounding electrode 9, the hollow nozzle corona electrode 10 is installed in the center of the cylindrical metal mesh grounding electrode 9, and is fixed on the upper cover of the plasma generator 4, and the bottom of the corona electrode 10 is The terminal and the mesh ground electrode 9 are located on the same horizontal plane, which is parallel to the gas-liquid interface. The hollow nozzle corona electrode 10 is connected to the positive p...

Embodiment 3

[0036]As shown in Figure 4, a device for synchronously purifying gas and liquid with high-voltage direct current / pulse discharge: it includes a high-voltage direct current power supply 1, which is sequentially opened with an air outlet 5, an air inlet 2, a liquid inlet 3, and a liquid outlet from top to bottom. The plasma generator 4 is composed of a cylindrical insulating shell 8 of 6, a set of hollow needle-shaped corona electrodes 15 and a circular metal mesh ground electrode 16. The circular metal mesh ground electrode 16 is placed inside the plasma generator 4, the upper end of the metal conductive rod 17 passes through the center of the upper cover of the cylindrical insulating shell 8, and the lower end is welded and fixed with the center of the circular metal mesh ground electrode 16, and the metal conductive rod is adjusted 17 up and down, so that the position of the circular metal mesh ground electrode 16 is higher than the air inlet 2, and connected to the power supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com