Electrically driven reverse mold moving and pulse pressure inducing injection molding process and apparatus

An injection device and pulsating pressure technology, applied in the field of injection molding methods and devices, can solve the problems of difficulty in improving the performance of plastic products, long molding cycle, uneven mixing, etc., to reduce oil pollution, fast filling speed, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

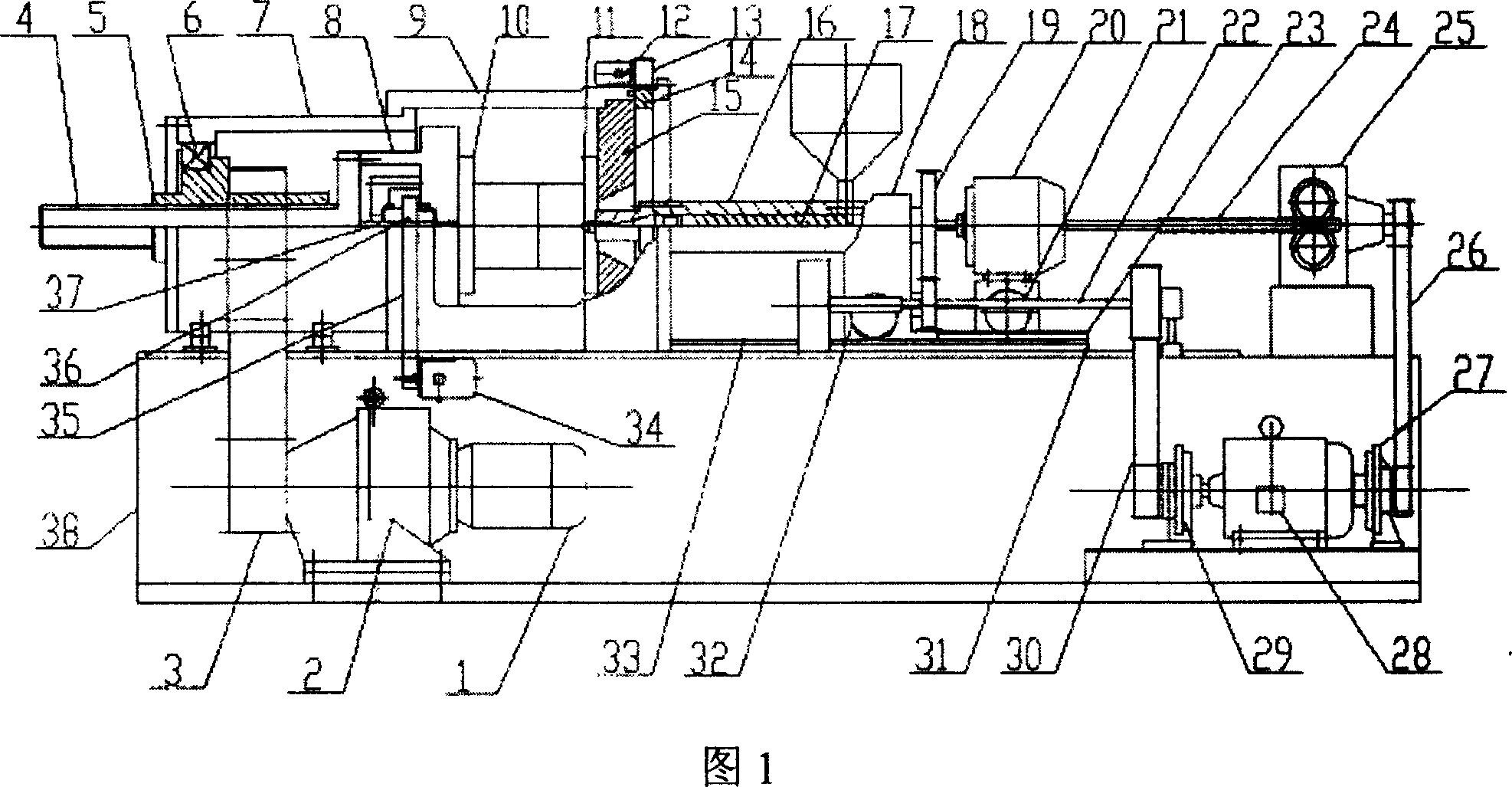

[0026] As shown in Figure 1, the polymeric material enters the barrel 16 from the hopper under the force of gravity. When plasticizing, the clutch 29 is closed, the clutch 27 is disconnected, the motor 28 drives the rolling spline shaft 22 to rotate through the synchronous belt 30, the rolling spline shaft 22 drives the screw 17 to rotate through the gear train 19, and the vibration generating device 20 works at the same time. 17. On the basis of circular motion, periodic axial vibration displacement is superimposed, so that the pulsating pressure caused by the mechanical vibration of the screw is introduced into the plasticizing process and acts on the melt, and plasticization is realized under the action of shear vibration and metering.

[0027] Hopper seat 18 is installed on the carriage 31, and carriage 31 can move along the guide rail on the support 38. And the rolling spline can move on the rolling spline shaft 22, so that the whole injection molding plasticizing device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com