Separation and refining process for rice bran polysaccharide

A rice bran polysaccharide, separation and purification technology is applied in the field of separation and purification methods of rice bran polysaccharide to achieve the effects of improving yield, scientific process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The preparation of embodiment 1 rice bran crude polysaccharide

[0018] Mix rice bran and deionized water according to the ratio of material to liquid 1:10, treat with 400W microwave for 2 minutes, then centrifuge at 3000rpm for 20min, take the supernatant, add α-amylase of pH 6.0 to hydrolyze for 1h, then centrifuge to get the supernatant Add protease at pH 4.5 to remove the protein after 1 h, and continue centrifuging for 30 min after 1 h, add 95% ethanol to the obtained supernatant to precipitate, so that the final ethanol concentration is 60%-90%. The next day, the precipitate was collected by centrifugation, and after dilution, it was dialyzed with a 3500 molecular weight dialysis bag, then rotated to evaporate, vacuum freeze-dried to obtain rice bran crude polysaccharide.

Embodiment 2

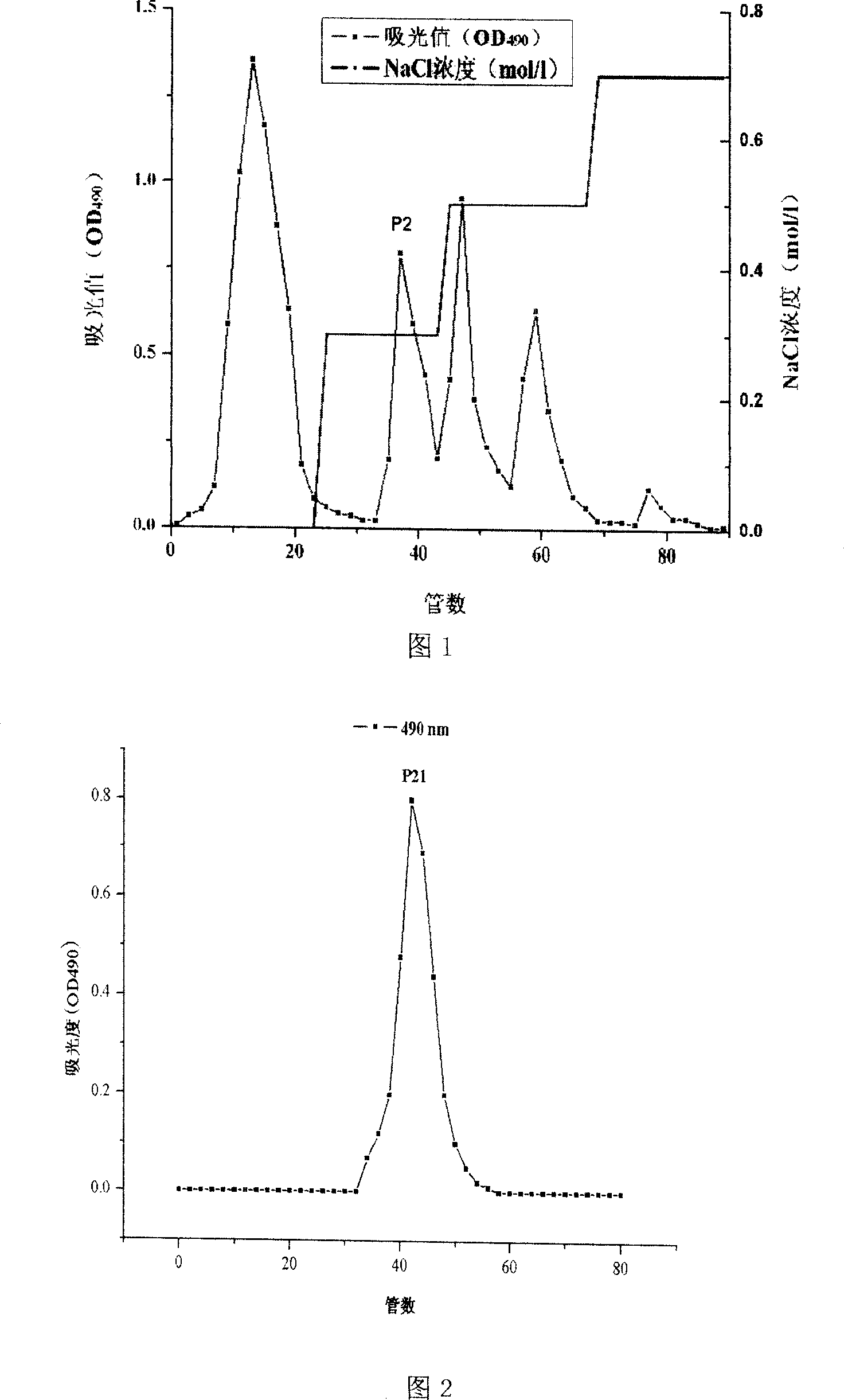

[0019] Example 2 Column Chromatography Separation and Purification of Rice Bran Polysaccharide

[0020] The crude polysaccharides from rice bran were eluted by Q-Sepharose Big Beads anion-exchange column chromatography.

[0021] Use 0.1mol / L, pH8 phosphate buffer as the eluent, load 25-30ml of crude polysaccharide sample, and then use 0, 0.3, 0.5 and 0.7mol / L NaCl solution respectively, use 1 column volume, A flow rate of 1.5 mL / min was used for stage elution on a Q-Sepharose Big Beads anion exchange column. 0.5mol / L NaCl solution eluted to get 2 peaks, and other concentration NaCl solutions eluted to get a peak. The P2 fraction obtained by the elution of 0.3mol / L NaCl solution was collected, and the sugar content of each peak was determined by the phenol-sulfuric acid method. In comparison, the elution peak of 0.3mol / L NaCl solution had higher sugar content and lower protein content. The collected P2 fraction was further purified by Sepharose CL-4B gel filtration column lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com