Air supply device and system of engine

An engine and air-saving technology, applied in the direction of machine/engine, etc., can solve the problems of high cost, low conversion efficiency, and inability to dynamically adjust the air-fuel ratio, so as to reduce emissions, ensure stability, and reduce fuel consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The realization principle of the present invention is to control the flow rate of the air supply by using the different openings of the throttle valve to reflect the load conditions of the engine through the linkage relationship between the air supply device and the throttle valve in the carburetor, and between the air supply device The amount of supplementary air to the engine is controlled by changing the area through which the airflow passes.

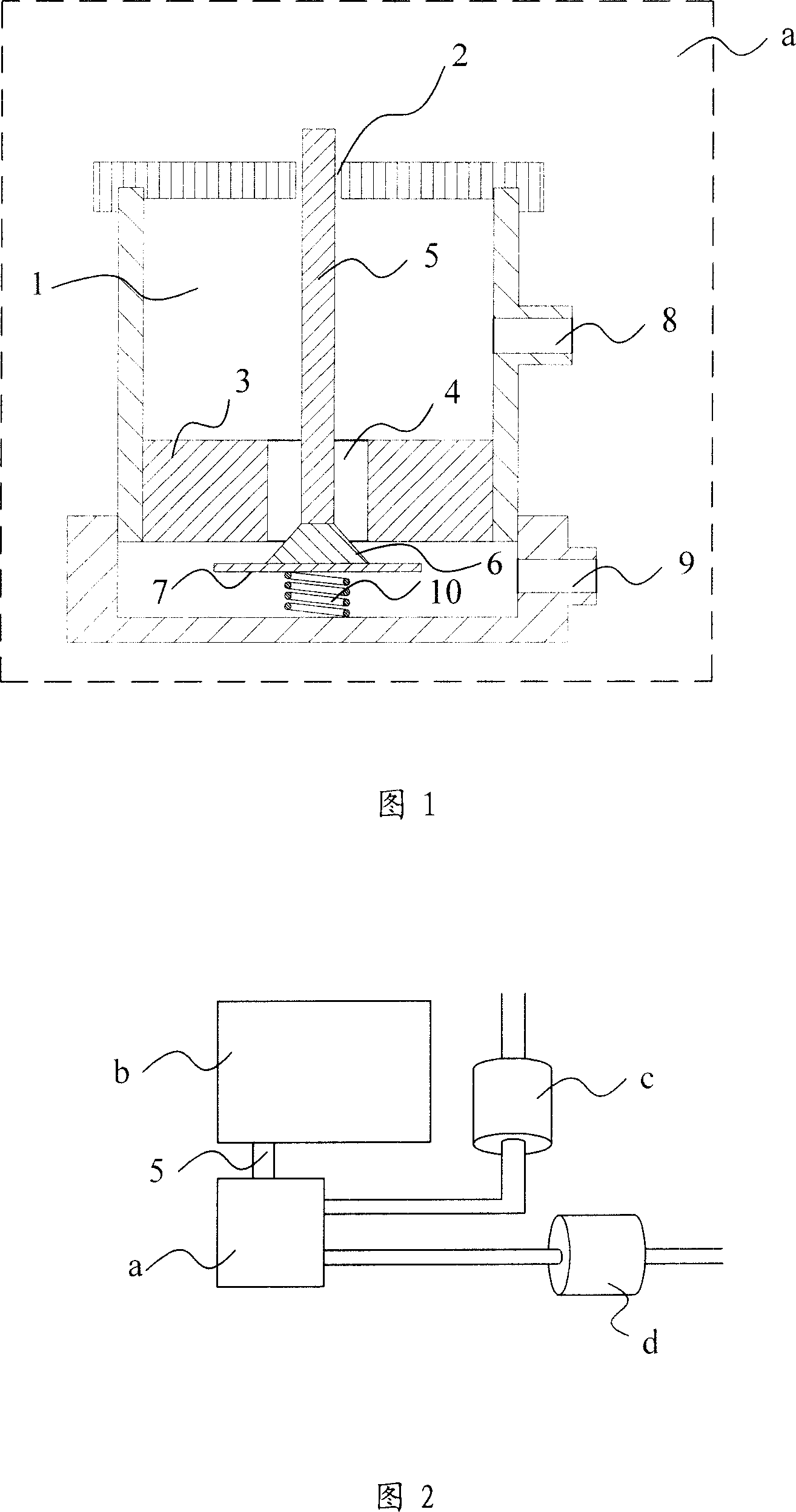

[0016] As shown in Figure 1, it is a schematic cross-sectional structure diagram of the engine air supply device of the present invention. The air supply device a is composed of the following components, including an air chamber 1, a communication hole 2, a throttle ring 3, a main metering hole 4, and a linkage rod 5 , Tapered oil needle 6, choke plate 7, air inlet 8 and air outlet 9. The function of the air chamber 1 is to accommodate air; the upper part of the air chamber 1 has a through hole as the communication hole 2, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com