Aqueous oxyhydrogen gas generator for use in IC engine

A generation device, a technology of hydrogen and oxygen, applied to internal combustion piston engines, oil supply devices, combustion engines, etc., can solve problems such as air pollution, car body hypoxia, suffocation and death, and achieve the effect of increasing mobility and solving hypoxia problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

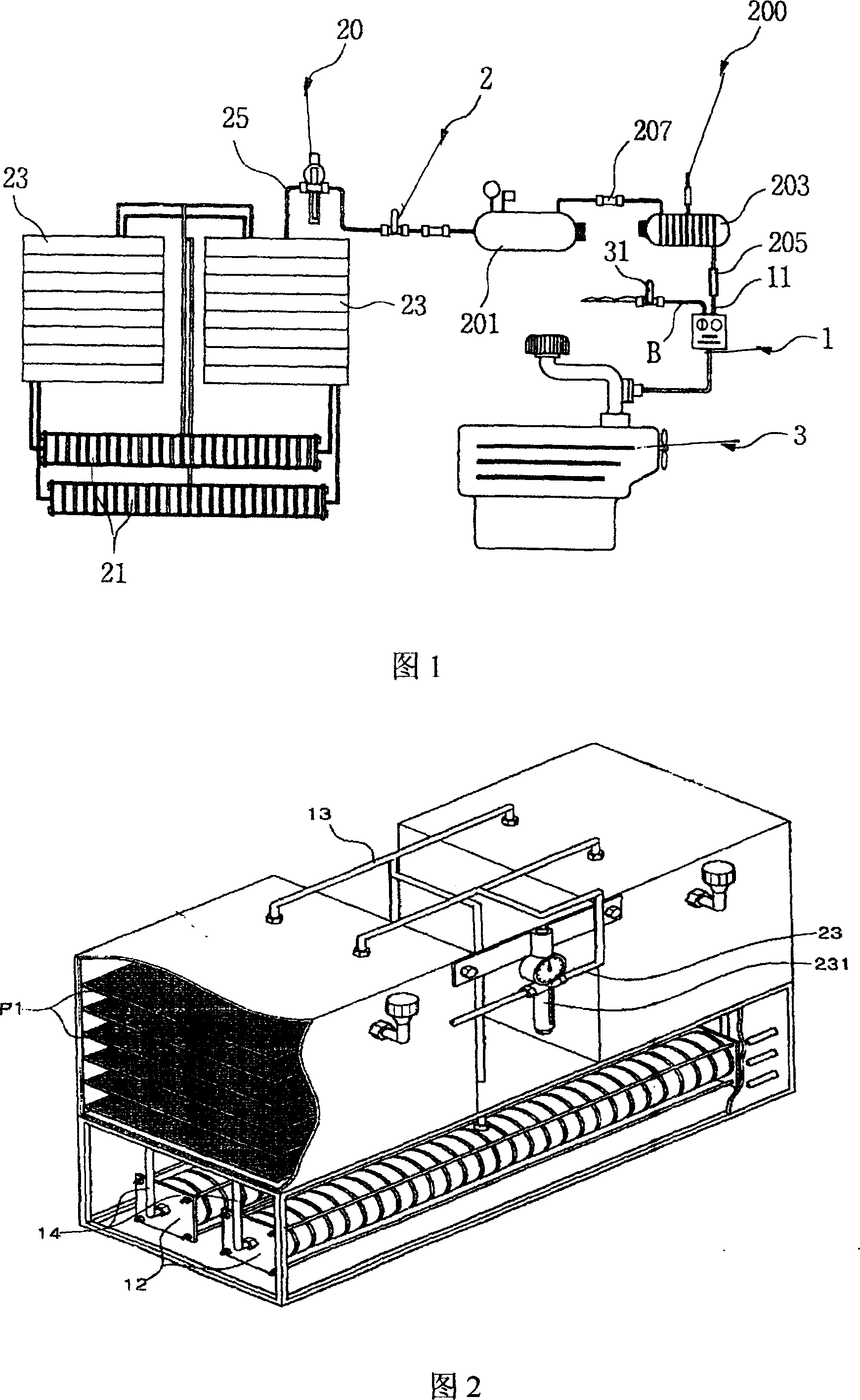

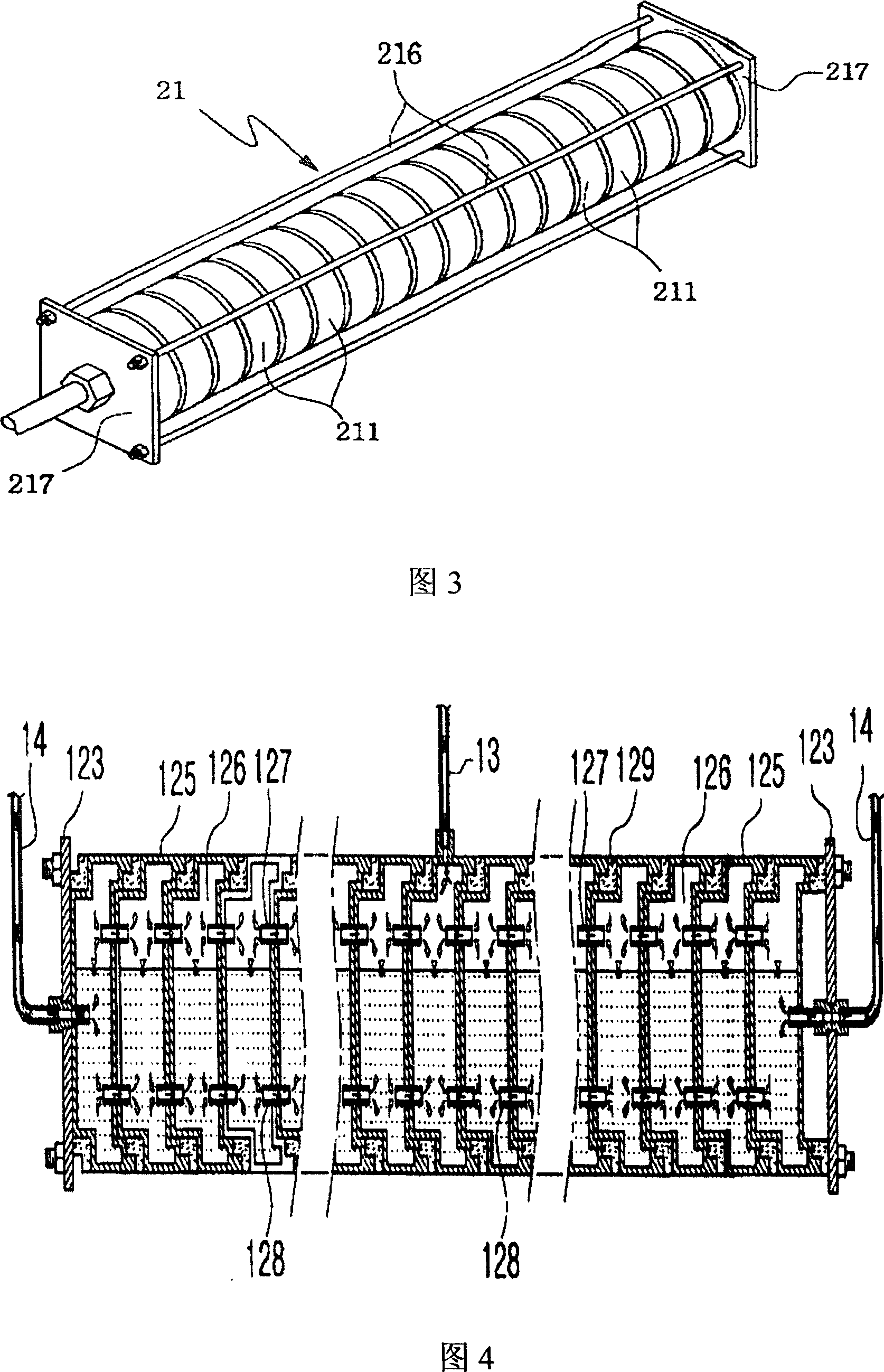

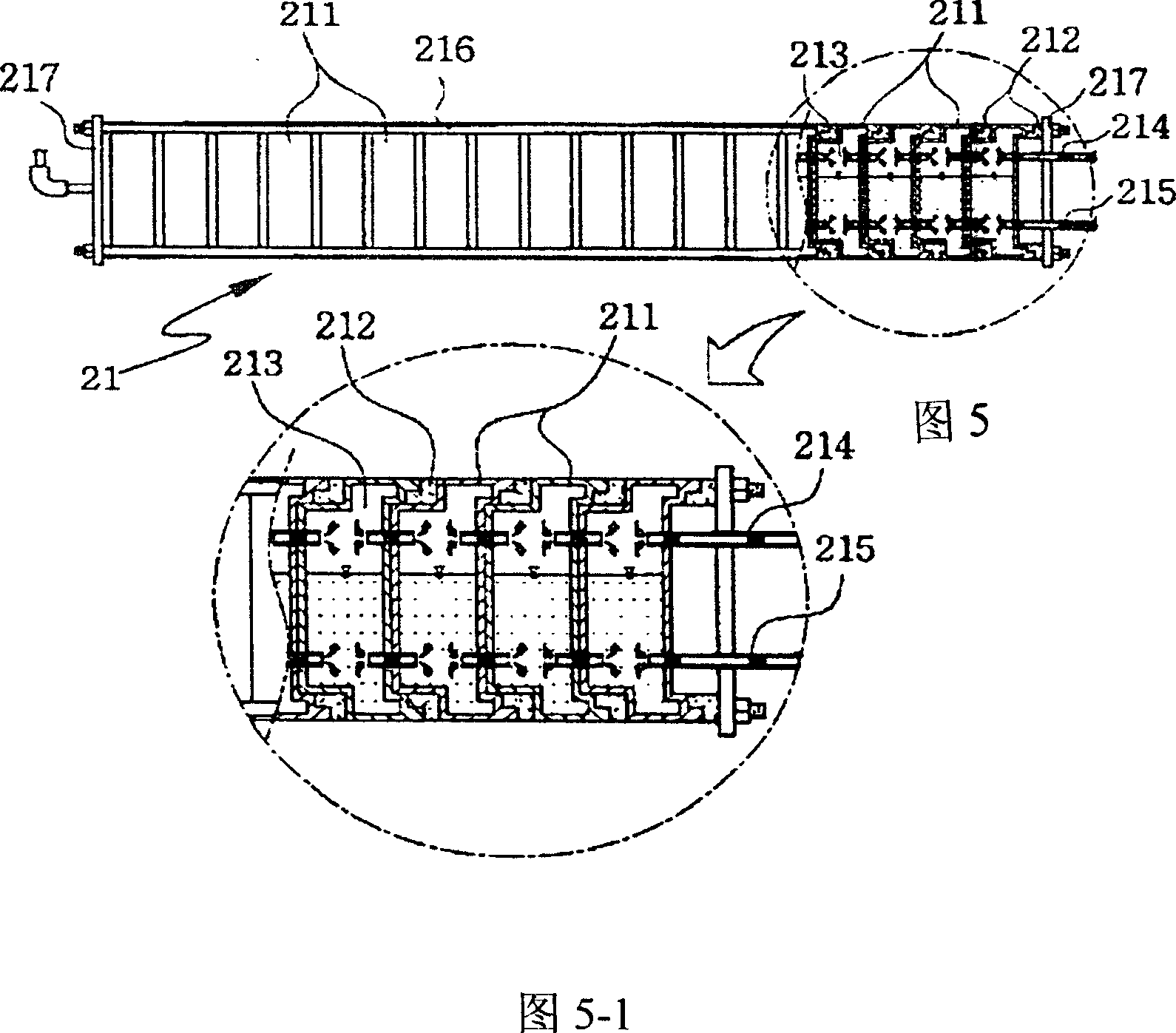

[0018] As shown in Figure 1, the water agent oxyhydrogen gas generating device that this internal combustion engine is used comprises the water agent oxyhydrogen gas separation tank 21 and the water reservoir 23, the gas storage buffer tank 201, One-way valve buffer tank 203, internal combustion combustion chamber 3, wherein the water reservoir 23 communicates with the water agent hydrogen-oxygen gas separation tank 21 through the liquid inlet pipe, and the water agent hydrogen-oxygen gas separation tank 21 communicates with the gas storage buffer tank through the hydrogen gas outlet pipe 25 201 is connected, the gas storage buffer tank 201 is connected to the one-way valve buffer tank 203 through the gas pipeline, the one-way valve buffer tank 203 is connected to the gas distribution valve 11 through the gas transmission pipeline, and the hydrocarbon input pipe B is also connected to the gas distribution valve In 11, the gas distribution output port 1 of the gas distribution v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com