Aqueous oxyhydrogen source gas burner multipurpose machine

A source gas and heat burner technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve problems such as physical and mental health hazards, environmental pollution, serious pollution, etc., to reduce pollution emissions, improve living environment, noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

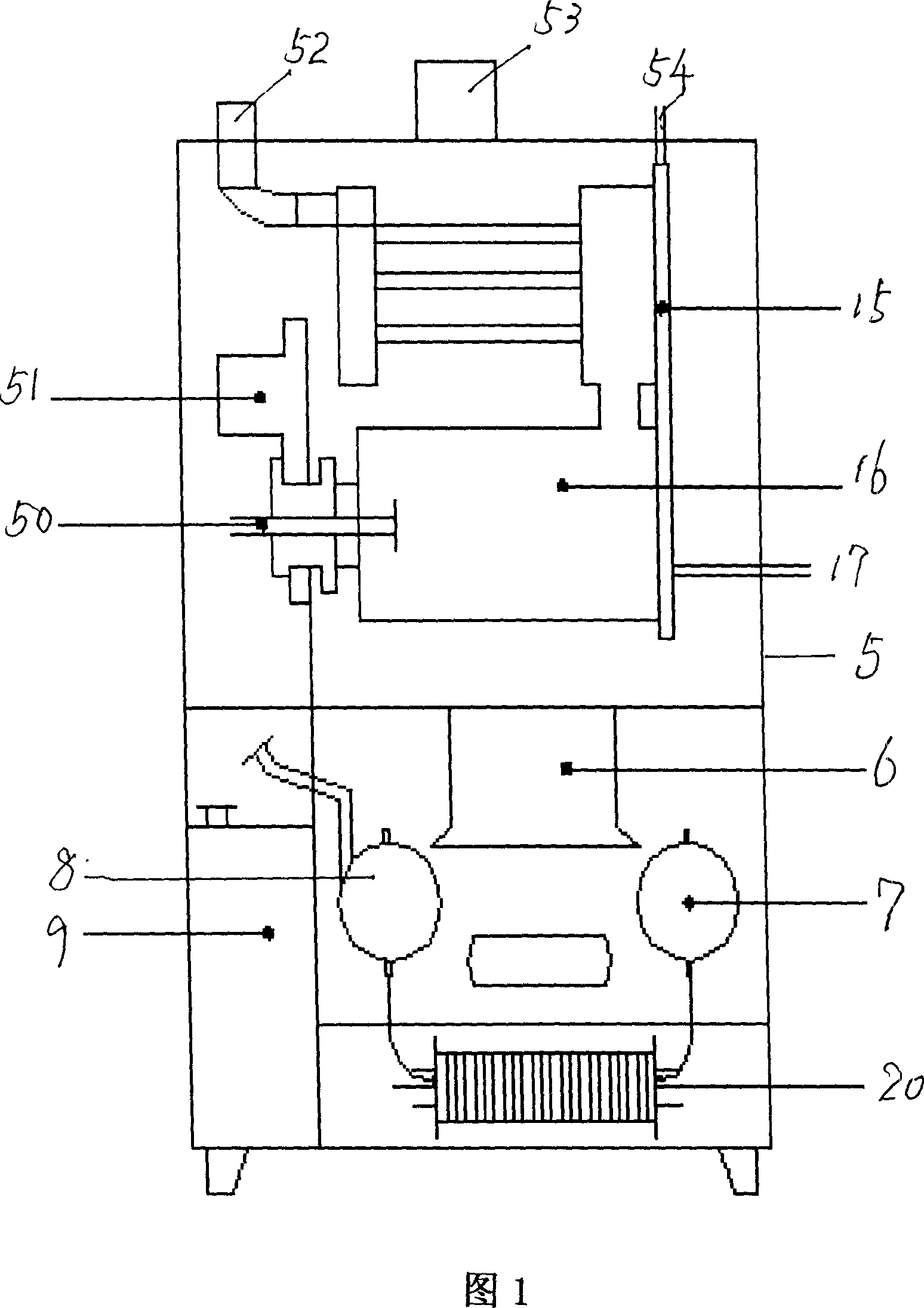

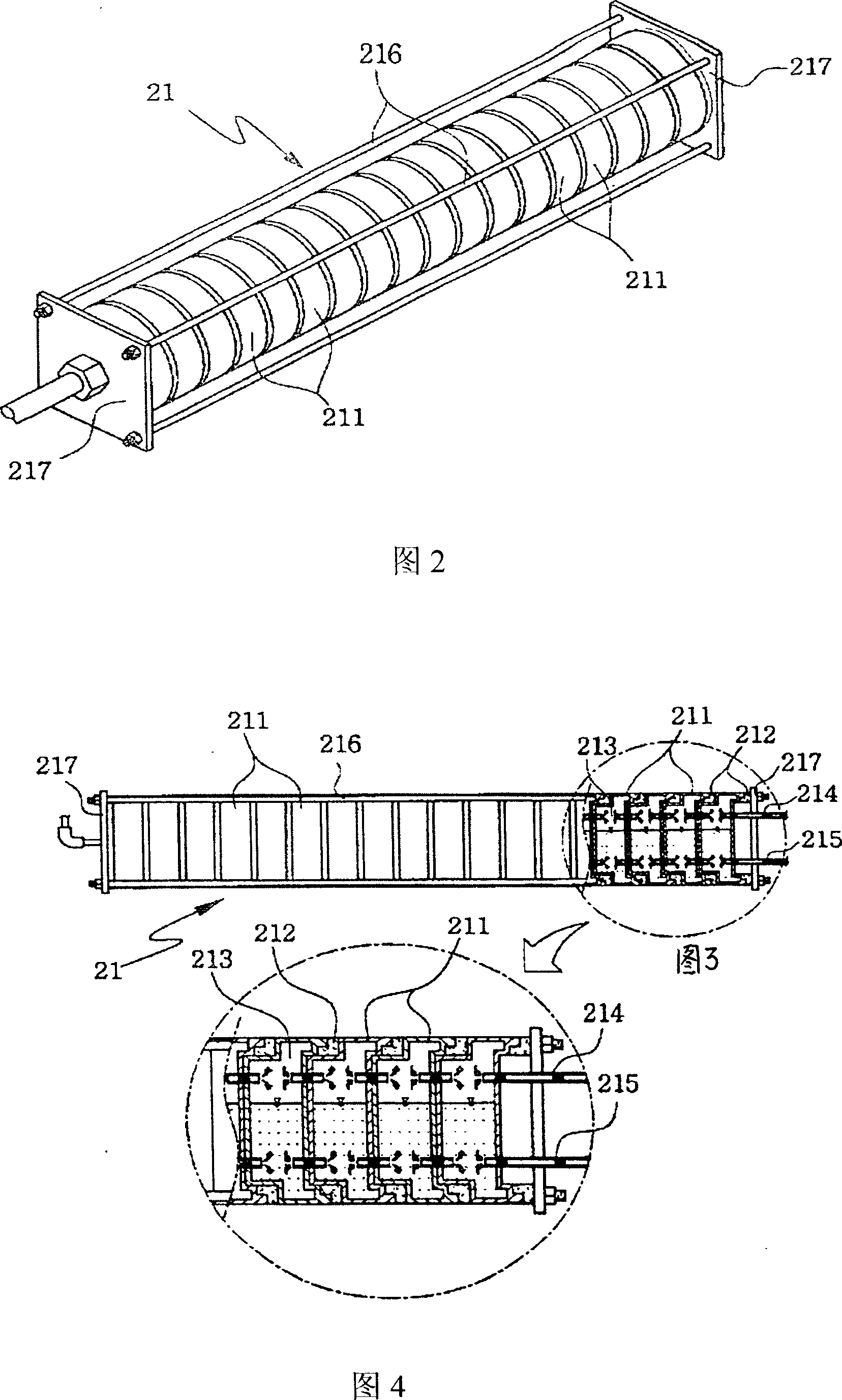

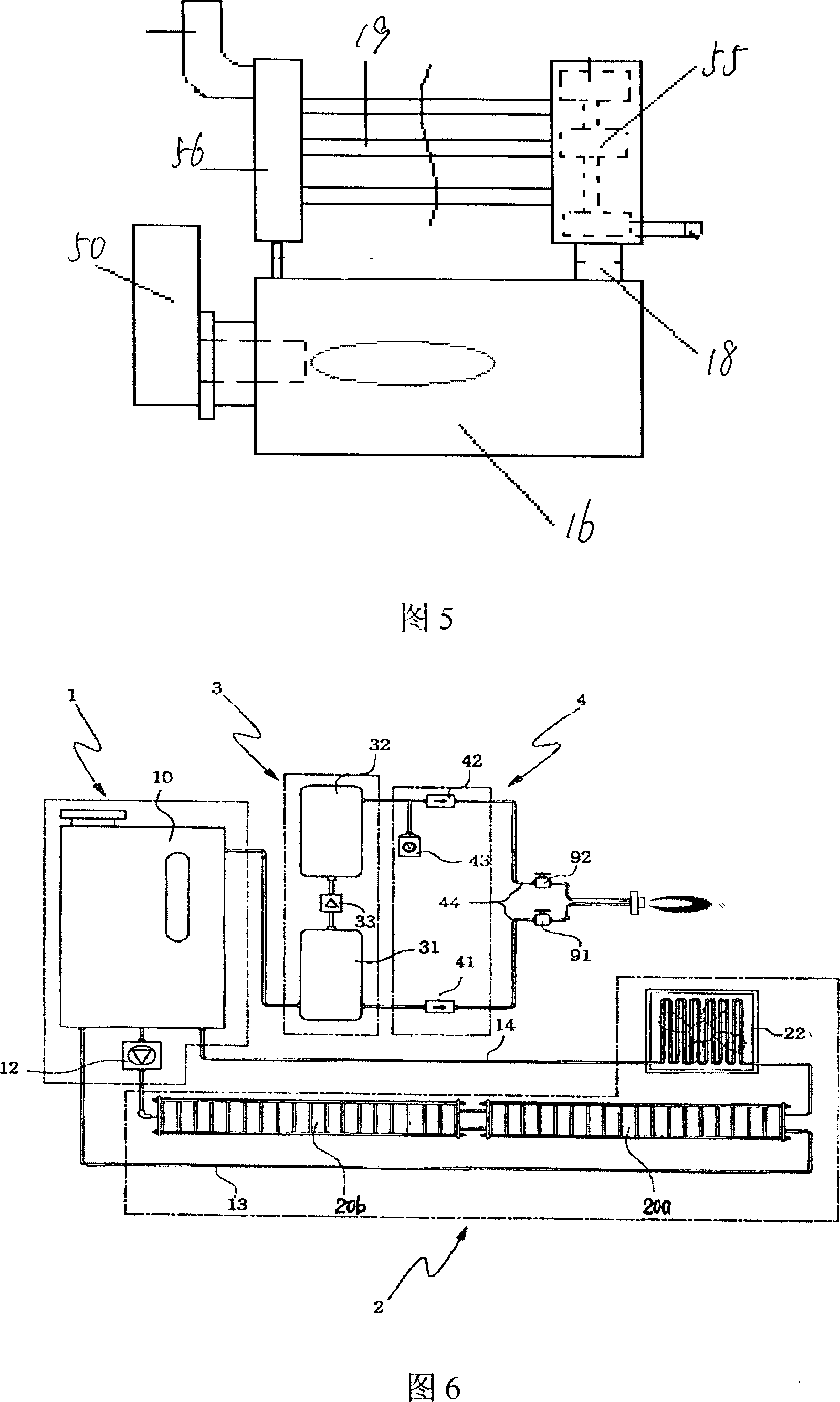

[0017] As shown in Figure 1, this water agent hydrogen and oxygen source gas burner multipurpose machine includes a housing 5, a gas generator 20, a water gas tank 7, a co-combustion agent container 9, a water storage device 8, and a gas distribution input pipe, gas nozzle 50, igniter 51, cold water pipe 17, combustion chamber 16, water tank 15, hot water pipe 54, hot air port 53, flue gas port 52, the lower part of the housing 5 is provided with a gas generator 20, the gas generator The top of the 20 is provided with a water-gas tank 7 and a water storage device 8, and the gas generator 20 communicates with the water-gas tank 7 and the water storage device 8 through a pipeline, and one side of the gas generator 20 is provided with a co-combustion agent container 9, The top of the gas generator 20 is also provided with a fan 6 and a combustion chamber 16, the co-combustion agent container 9 communicates with the gas nozzle 50 through the gas distribution input pipe, and the hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com