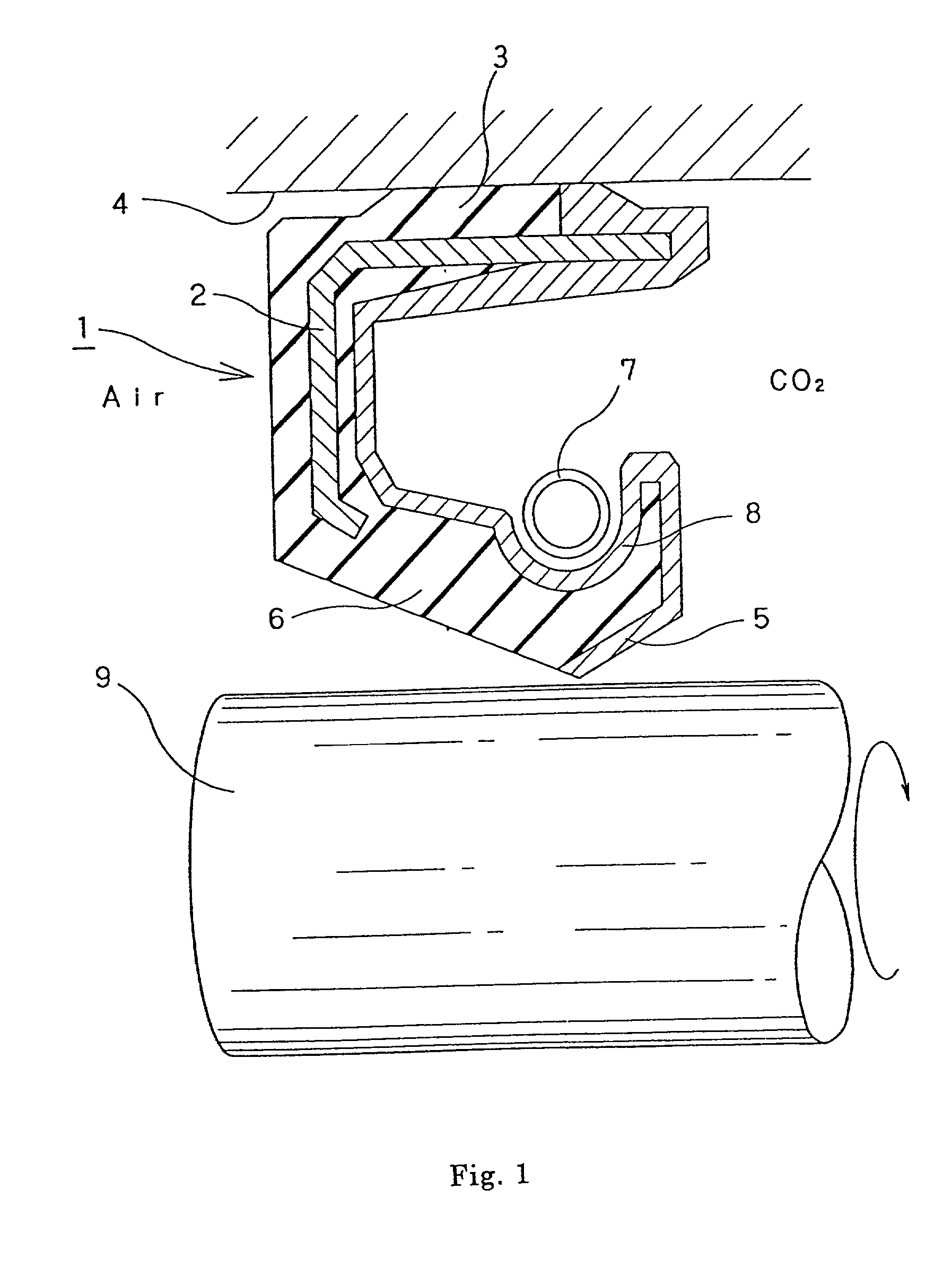

Method of preparing a molded sealing composition for sealing against permeation of carbon dioxide gas

a technology of carbon dioxide gas and sealing composition, which is applied in the direction of transportation and packaging, special tyres, fibre treatment, etc., can solve the problems of easy blistering, inability to use sealing devices, and inability to withstand swelling and blistering of sealing materials, and achieve excellent anti-permeability to carbon dioxide gas and the resistance of swelling and blistering, excellent bonding strength, and the effect of eliminating the cost of the adhesion process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

46.

1 Fluoro thermoplastic elastomer 100 phr (Daikin product Daiel-Thermo T-630) FEF carbon black 35 phr Magnesium oxide 5 phr Organic peroxide 1.5 phr (Nippon Yusi product Percumyl D) Triallyl isocyanurate 3 phr (Nihon Kasei product Taic M60, 60%)

47. Ingredients except for an organic peroxide were mixed using a 3L kneader and further kneaded on a heating roll (80.degree. C.), and finally the organic peroxide was mixed. The thus obtained thermoplastic elastomer composition was press vulcanized at the temperature of 195.degree. C. for 8 minutes and then oven cured (secondary vulcanization) at 200.degree. C. for 15 hours to make two discoid sheets with a diameter of 90 mm and thickness of 0.5 mm. One of these sheets was assigned to a discoid sample with a diameter of 50 mm and the other was punched to make a squared sample with a size of 30.times.30 mm.

48. The discoid sample was used for measuring carbon dioxide permeability (cm.sup.3.multidot.mm / m.sup.2.multidot.atm.multidot.24 hours)...

example 2

49. In Example 1, ten (10) phr of FEF carbon black was used instead of 35 phr of FEF carbon black, and 30 phr of acetone and 10 phr of methanol were further added.

example 3

50. In Example 2, same amount of silica (Aerosil Co. product, A200) was used instead of FEF carbon black.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com