[0015] The present invention improves upon the applicants' aforementioned U.S. Pat. No. 5,922,147 patent by simplifying even further the overall heat-treatment of the castings, although broadly it can be applied separately. The invention dispenses with the aging furnace, in addition to preferably also dispensing with the solution furnace. Therefore, it provides a method and apparatus for producing the casting in a considerably shorter time, with less capital, and lower production costs, while maintaining and even improving on required mechanical properties of the castings.

[0016] In order to better describe the invention, the applicants specifically identify the two major parts of the casting as a riser portion (the riser portion being that portion which is subsequently removed and discarded) and a workpiece portion (the workpiece portion being the portion used for the end product). A "riser" is a reservoir of

liquid metal used to largely compensate for shrinkage of a casting as it cools in its mold. The term "riser" also commonly has the meaning used in this application, namely the solidified

metal portion of the casting remaining in the reservoir after the casting is cooled. "Riser portion" is intended to include at least the riser and additionally in its broader sense can include other similar waste attachments such as

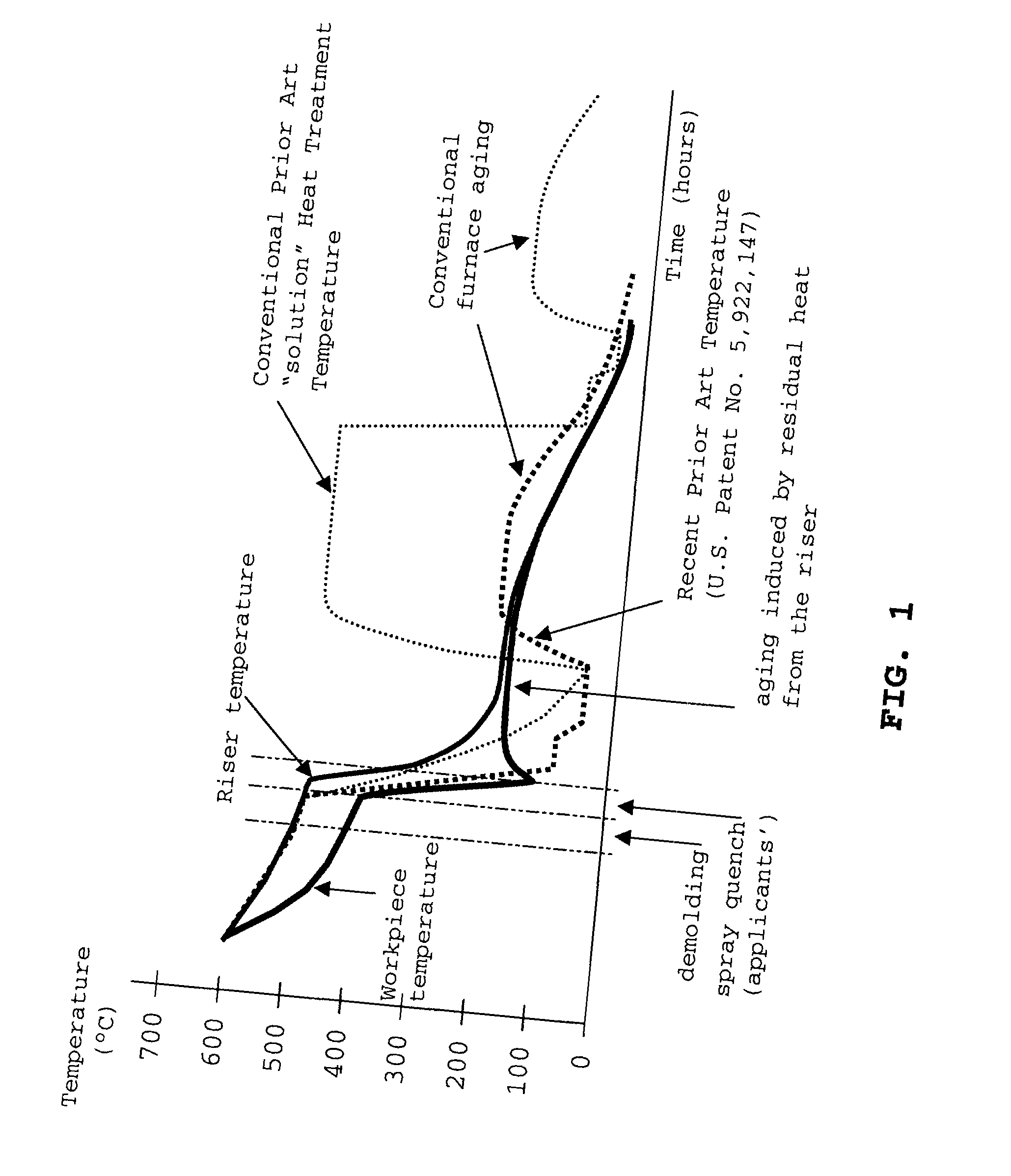

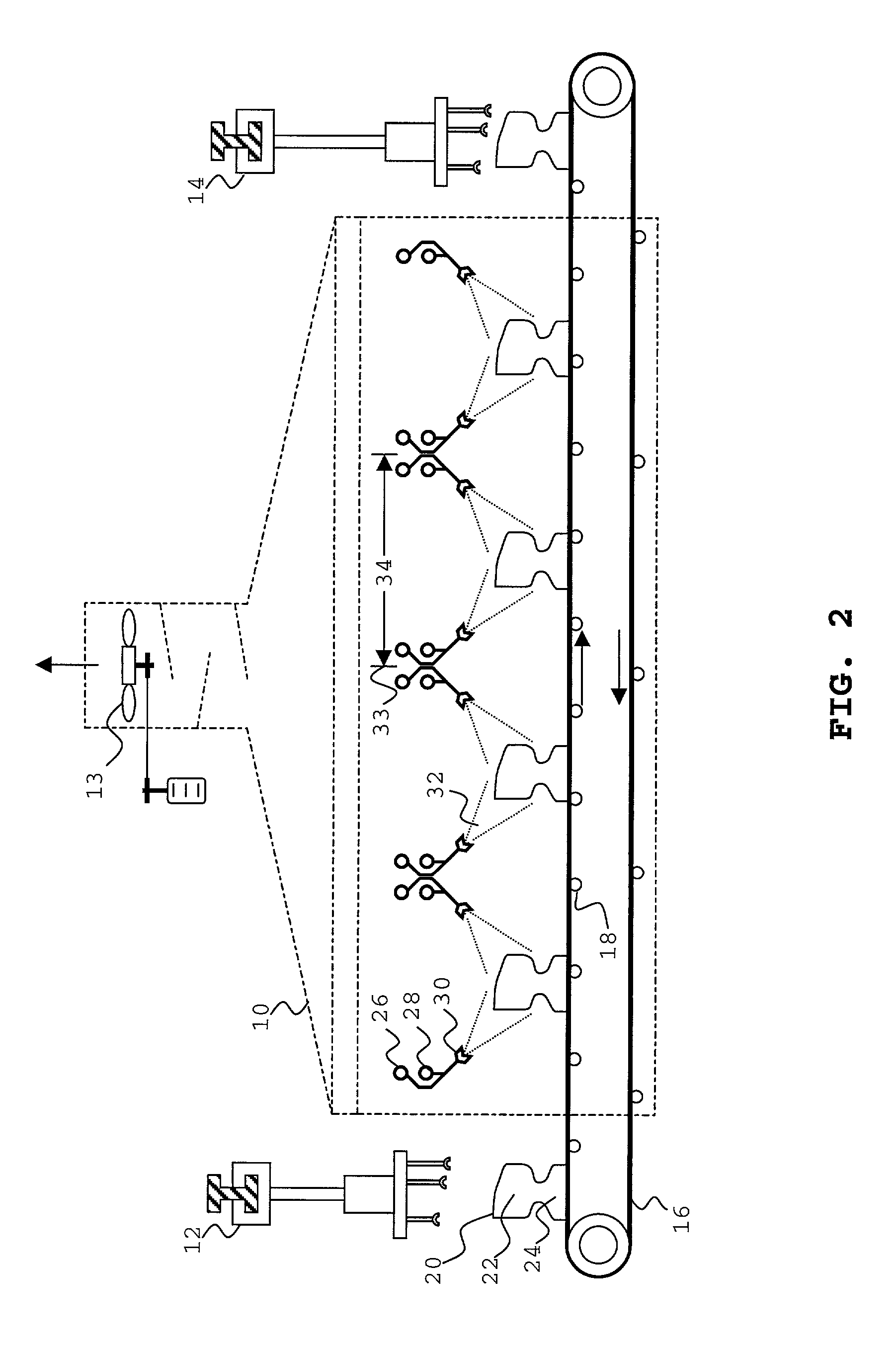

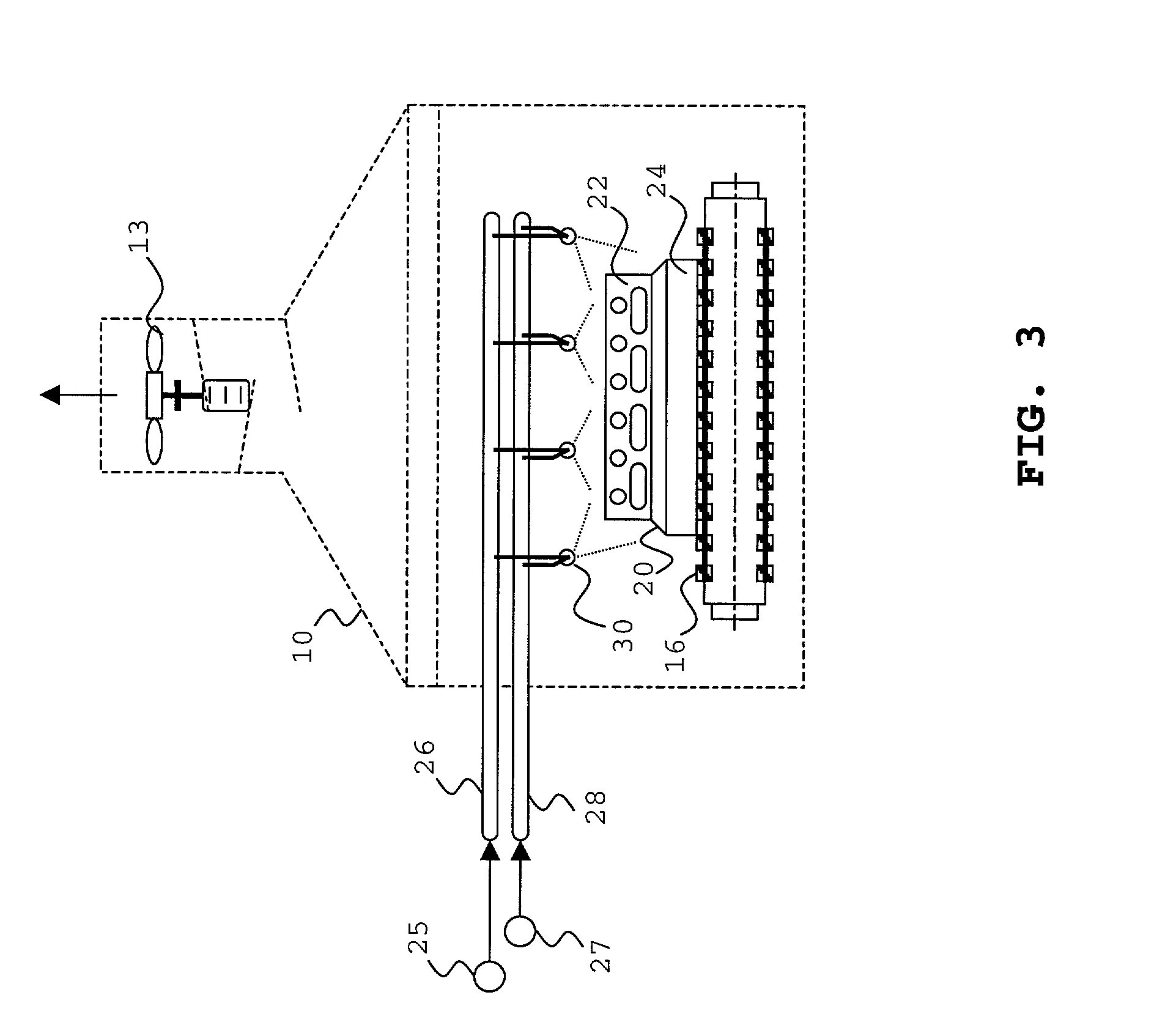

sprue, runners, gates, etc. formed as part of the original casting. When the casting is demolded from the typical water-cooled mold, the workpiece commonly has a temperature of about 400.degree. C. and the riser one of about 500.degree. C. The invention achieves its advantages by a selective quench of only the workpiece portion to surface temperatures preferably in the range from above about 100.degree. C. to about 130.degree. C., at a rate sufficient to achieve a supersaturated solution of the hardening element (typically

copper) in the aluminum

alloy of the workpiece at the atomic level. To perform this selective quench, spray nozzles are set to direct the

water spray or mist on the workpiece and minimize any impingement on the riser. This workpiece-directed quench permits the riser (subjected only to natural or at most a minimized indirect cooling) to maintain a significantly higher temperature typically above about at least 300.degree. C. to 350.degree. C. during the workpiece quenching step. Thereafter, when the quenching is finished, the residual heat in the

sprue portion is used as a heat reservoir to slightly re-heat the workpiece and maintain it (by conductive phenomena) in the

artificial aging temperature range of between 140.degree. C. and 250.degree. C., and preferably about 180.degree. C. to about 220.degree. C., for an adequate time period, to thus achieve the desired properties for the workpiece. The invention dispenses with the need to supply furnace heat for re-heating and maintaining the whole casting in the artificial aging temperature range and simplifies the casting

plant by thus rendering the aging furnace unnecessary. The final quench temperature should not be so low that the residual heat from the riser is too little to maintain the workpiece in the required aging temperature range for the necessary length of time. Also, if the workpiece surface temperature is maintained high enough above the

boiling point of the spray liquid (typically water) throughout the quench, then liquid overflow onto the riser can be more easily minimized or avoided altogether and the

latent heat of can be utilized and concentrated on the workpiece. A copious flow of a fine water mist is especially effective, since the mist particles evaporate immediately and there is no liquid

wetting of the hot workpiece surface that can flow over onto the riser.

[0018] Even though the temperature of the workpiece and the riser greatly depends on the

mass and the surface area of both portions, the quenching temperature can be regulated to achieve the advantages of the invention at different temperature paths. Also the aging position of the casting

plant can be insulated to prolong the artificial aging step at elevated temperatures for a more

extended time period as may be needed (or even make use of a

heat exchanger to take

advantage of other residual or

excess heat sources that may be available elsewhere in the casting

plant system), all as an aid to avoid the need for the added expense of an aging furnace.

[0020] It is a further object of the invention to increase the productivity of a casting plant and to reduce its capital costs and its operating costs significantly.

Login to View More

Login to View More