Carbon dioxide blown low density, flexible microcellular elastomers suitable for preparing shoe components

a microcellular elastomer and low density technology, applied in the field of carbon dioxide blown low density, flexible microcellular elastomers suitable for preparing shoe components, can solve the problems of exceptionally difficult production of water-blown microcellular foam, and achieve the effects of low density, low density and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

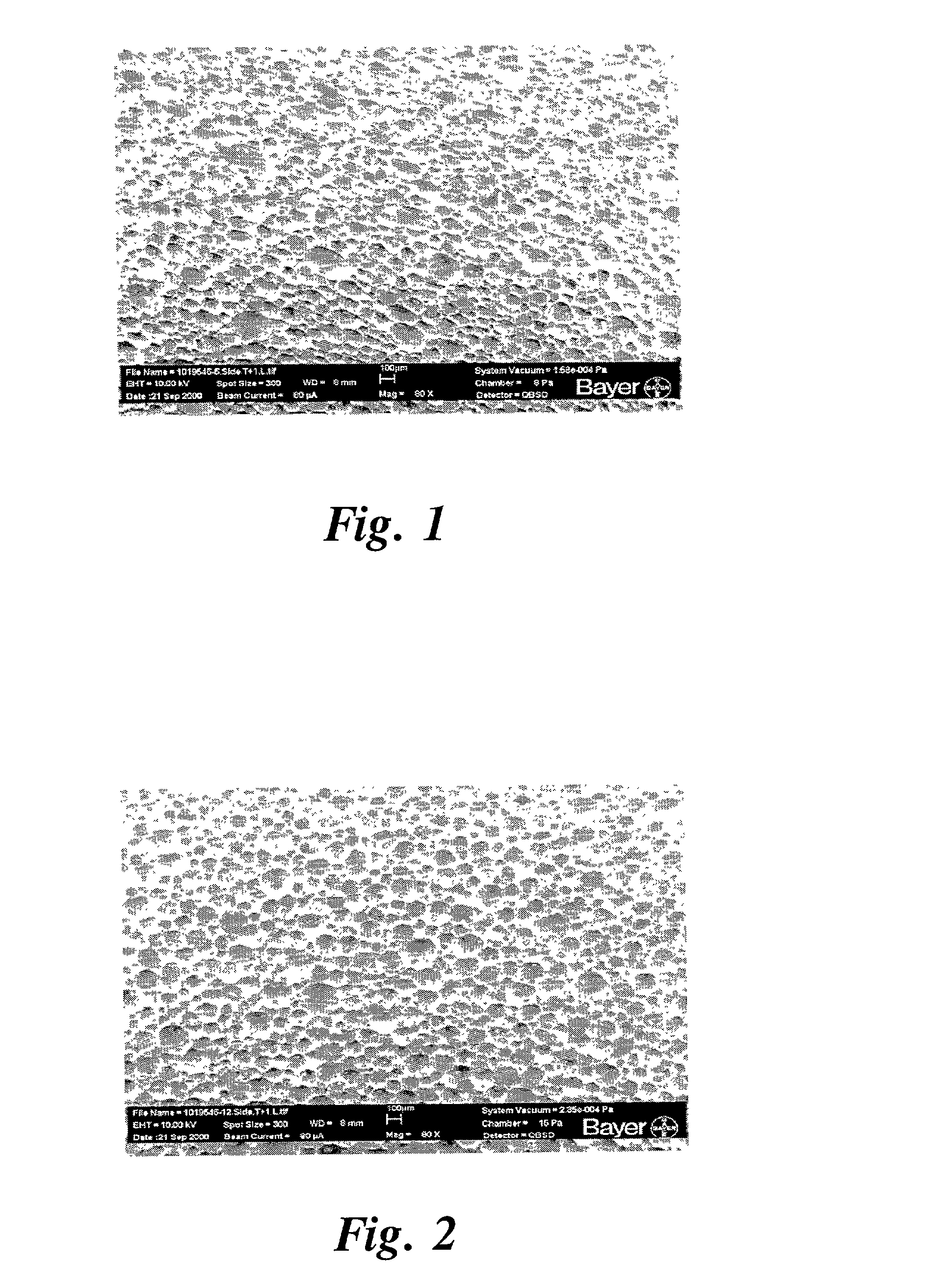

Image

Examples

example 1

[0031] In the above formulation 1.0 g / l of CO.sub.2 was dissolved in the prepolymer side and 0.1 g / l CO.sub.2 was dissolved in the polyol side. The tanks were maintained at 50 psi and 35 degrees .degree. C. This resulted in foam densities of the separate components at atmospheric pressure of 0.52 and 0.95 g / cm.sup.3 respectively. The two components were mixed at a ratio of 0.84 using a low pressure machine and the material allowed to flow and expand into a 10 mm thick mold.

example 2

[0032] In the above formulation 1.4 g / l of CO.sub.2 was dissolved in the prepolymer side and 0.95 g / l CO.sub.2 was dissolved in the polyol side. The tanks were maintained at 50 psi and 35 degrees .degree. C. This resulted in individual foam densities at atmospheric pressure of 0.31 and 0.51 g / cm.sup.3 respectively. The two components were mixed at a ratio of 0.84 using a low pressure machine and the material allowed to flow and expand into a 10 mm thick mold.

example 3

[0033] In the above formulation 1.5 g / l of CO.sub.2 was dissolved in the prepolymer side and 1.25 g / l CO.sub.2 was dissolved in the polyol side. The tanks were maintained at 50 psi and 35 degrees .degree. C. This resulted in foam densities at atmospheric pressure of 0.25 and 0.37 g / cm.sup.3 respectively. The two components were mixed at a ratio of 0.84 using a low pressure machine and the material allowed to flow and expand into a 10 mm thick mold.

[0034] The properties obtained from these examples are compared in the following table:

1 TABLE 1 Example 1 Example 2 Example 3 Part Density, g / cm.sup.3 0.64 0.43 0.23 Hardness, Asker C 82 69 36 Tensile Str. Kg / cm.sup.2 56 30 10 Split Tear, kg / cm 4.9 3.0 1.8 C Tear, kg / cm 19.6 11.7 6.2 Resilience 42 41 37

[0035] As can be seen, the subject invention process produces elastomers with high hardness values. Even at an ultra-low density of about 0.23 g / cm.sup.3, the hardness is still 36 on the Asker C scale, and the resilience quite high as well,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com