Board for mounting BGA semiconductor chip thereon, semiconductor device, and methods of fabricating such board and semiconductor device

a technology of bga semiconductor chips and semiconductor devices, which is applied in the manufacture of printed circuits, printed circuit aspects, basic electric elements, etc., can solve problems such as solder failures, reducing the reliability of connections over a long period, and affecting the reliability of connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

first embodiment

[0069] A method of fabricating semiconductor device 1 shown in FIGS. 4 and 6A through 6D according to the present invention will be described below with reference to FIGS. 9 and 10A through 13E.

[0070] Metal sheet 8 (see FIG. 8) for use as a matrix sheet for insulating layer 3 is prepared. For example, a metal sheet KFC (trade name, thickness 0.25 mm) manufactured by Kobe Steel, which is a copper sheet according to U.S. CDA standard C19210, is prepared. Metal sheet 8 is not limited to the material and thickness described above. Metal sheet 8 may be any metal sheet insofar as it is a good electric conductor for use as a cathode in a subsequent plating process, can be chemically dissolvable by an etchant, and can serve as a support plate for stacking insulating layer 3 and conductive layer 2 thereon. Metal sheet 8 may be a steel sheet, a nickel sheet, a stainless steel sheet, a sheet of an alloy of these metals, or a sheet plated with these metals, other than a copper sheet. The thickn...

2nd embodiment

[0088] A method of fabricating semiconductor device 1 according to a second embodiment will be described below with reference to FIGS. 10A through 10E, 11A through 11C, 14, 15A through 15F, and 16A through 16E. Those steps which are identical to those of the method according to the first embodiment will be described only briefly.

[0089] As with the first embodiment, the surface of copper sheet 8 shown in FIG. 10A is polished in step S1, and as shown in FIG. 10B, etching resists 9, 10 are laminated on respective opposite surfaces of copper sheet 8 in step S2. As shown in FIG. 10C, etching resist 9 on one surface of copper sheet 8 is patterned in step S3. Then, as shown in FIG. 10D, the areas of copper sheet 8 which are not covered with etching resist 9 are etched to a uniform depth in step S4. Then, as shown in FIG. 10E, photosensitive etching resists 9, 10 are removed.in step S5. Then, as shown in FIGS. 11A through 11DC, the entire surface of copper sheet 8 is etched again to remove ...

second embodiment

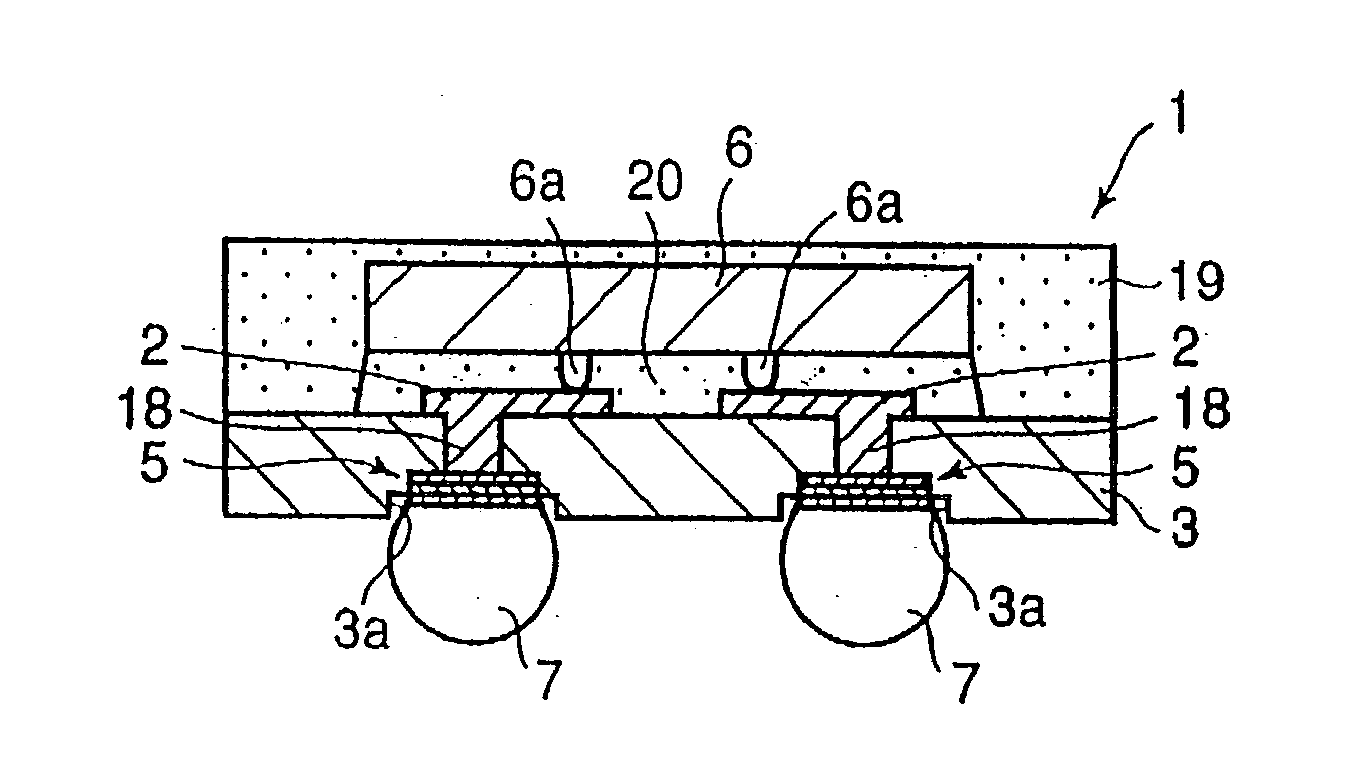

[0095] Then, a resin sheet with a copper foil, which has an insulating resin layer having a thickness ranging from 35 to 80 .mu.m and coated with an epoxy resin which is then partly cured, is placed on first insulating layer 21 and subjected to laminating press process. The copper foil is then removed by a copper etching process, forming second insulating layer 23 in step S24, as shown in FIG. 16A. In the second embodiment, therefore, two-layer insulating layer (interlayer insulating layer) 24 comprising first insulating layer 21 and second insulating layer 23 is constructed.

[0096] Then, as shown in FIG. 16B, via holes 23a are formed in second insulating layer 23, and epoxy resin scum is.removed therefrom by a desmearing process. Using copper sheet 8 as a cathode, an electric copper plating process is carried out to form a plated layer, which is patterned, producing vias 18 embedded in via holes 23a and conductive layer 2 serving as circuits in step S14, as shown in FIG. 16C.

[0097] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electrical conductor | aaaaa | aaaaa |

| aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com