Mini-CPO providing hydrogen for hydrogen desulfurization of hydrocarbon feeds

a technology of hydrocarbon feeds and hydrogen desulfurization, which is applied in the direction of combustible gas production, electrochemical generators, chemistry apparatuses and processes, etc., can solve the problems of affecting the reduction of sulfur level, consuming on the order of 2 kw of power, and high cost of hydrocarbon blower 30. , to achieve the effect of improving hydrogen generation, no operation energy, and less humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

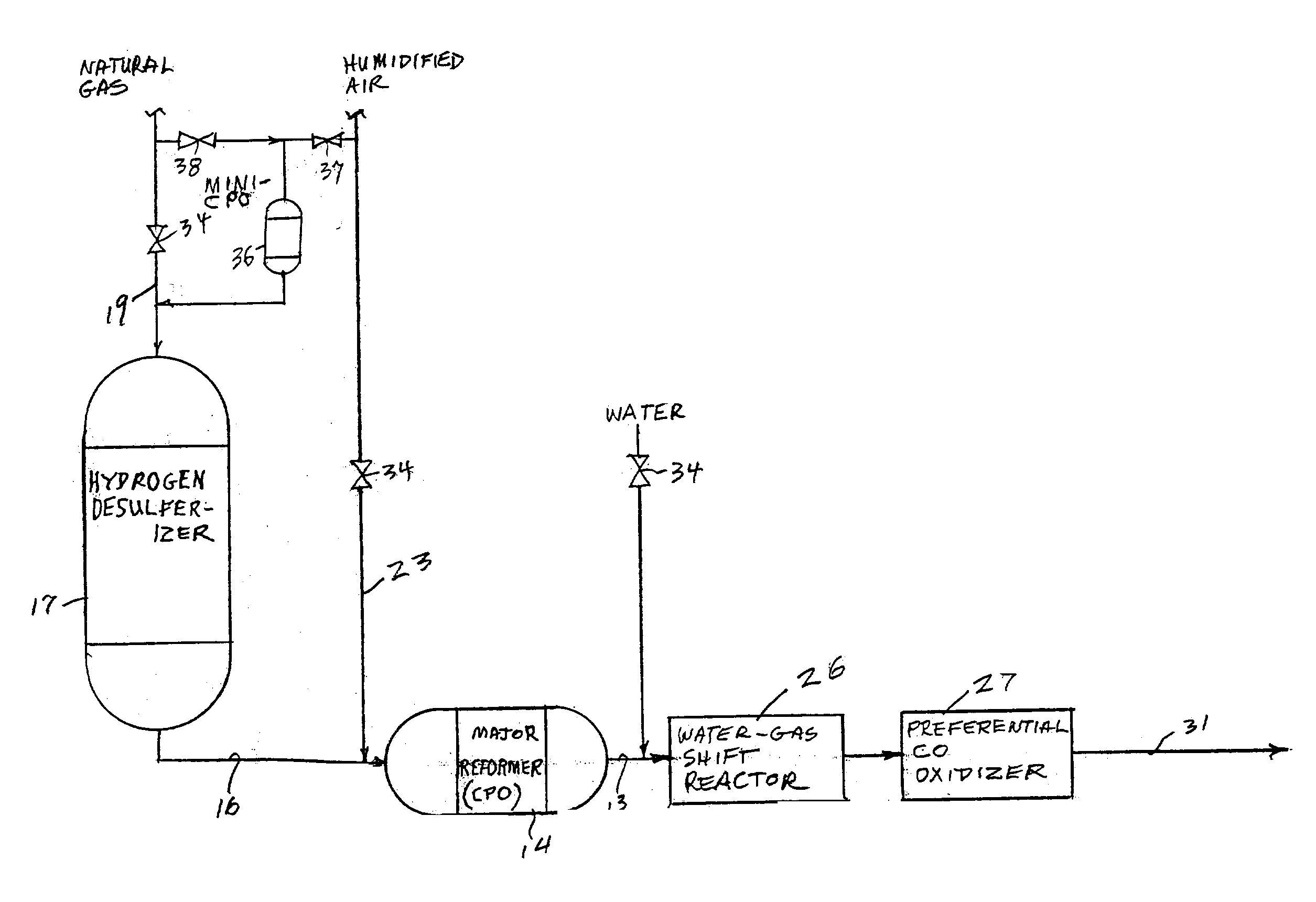

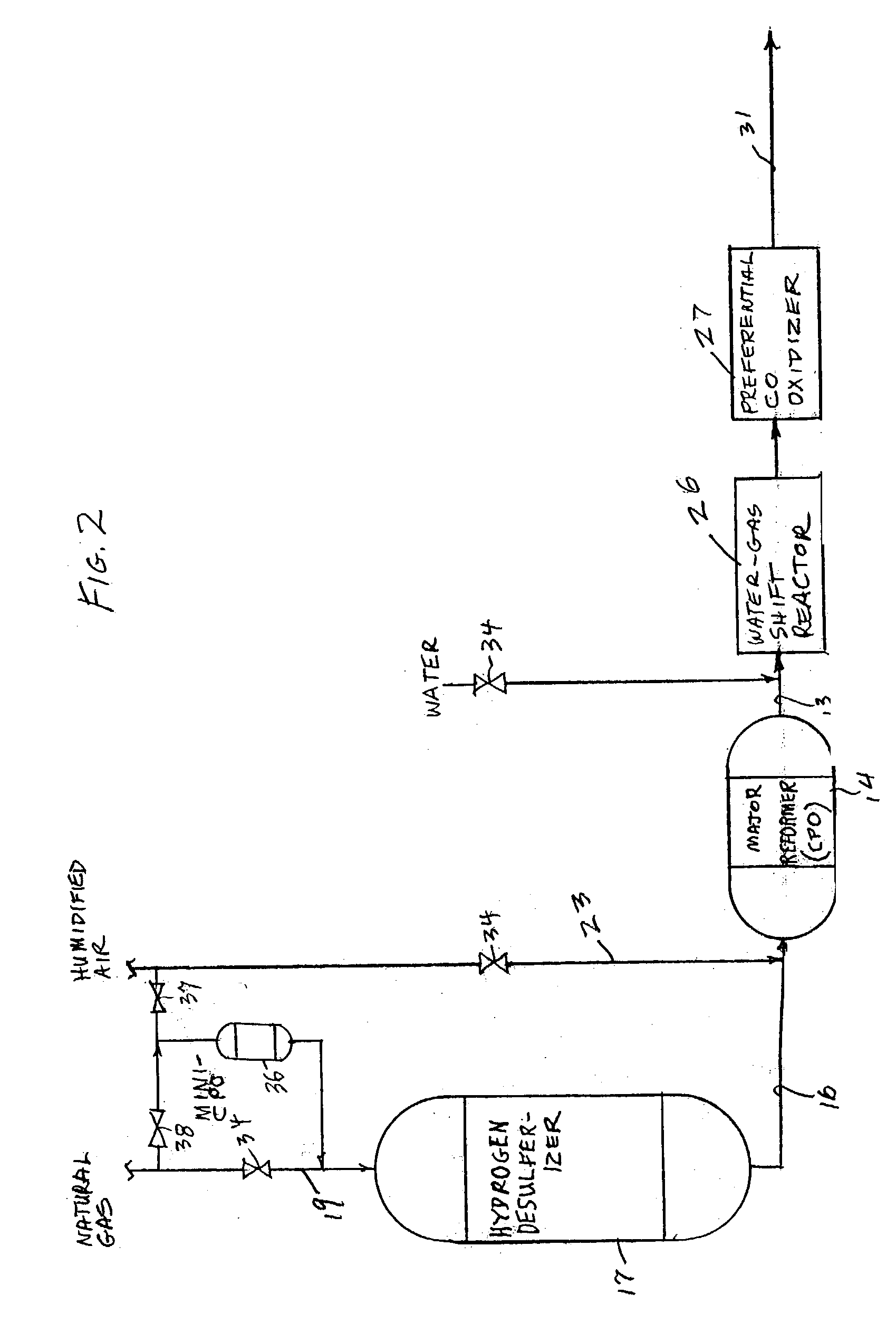

[0015] Referring to FIG. 2, a mini-CPO 36, about the size of a 12 ounce beverage can, receives humidified air through a valve 37 and receives hydrocarbon fuel, such as natural gas, through a fixed orifice 38. The multiplicity of valves and the fixed orifice allows adjusting the correct flows to the mini-CPO, the hydrogen desulfurizer and the major reformer. In the mini-CPO, the fuel, which for natural gas, is typically more than 99% methane with traces of sulfur compounds, nitrogen and other hydrocarbons, is converted, along with the humidified air, to reformate, which may comprise roughly 30% hydrogen, 12% CO, and small amounts of other gases such as CO.sub.2 and H.sub.2O, nitrogen from the humidifier, and unconverted hydrocarbons.

[0016] The reformate produced by the mini-CPO 36 in a line 38 is mixed with the fuel at the inlet to the hydrogen desulfurizer 17. Since no water is applied to the mini-CPO, the reformate is much drier than the reformate generated in the line 31 by the wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com