Method to provide wear-resistant coating and related coated articles

a coating and coating technology, applied in the field of coating articles, can solve the problems of change of tolerance, inefficiency of component performance, dimensional form, etc., and achieve the effect of increasing the useful life of articles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Comparison Between Coatings With Coated Diamond Particles and Uncoated Diamond Particles

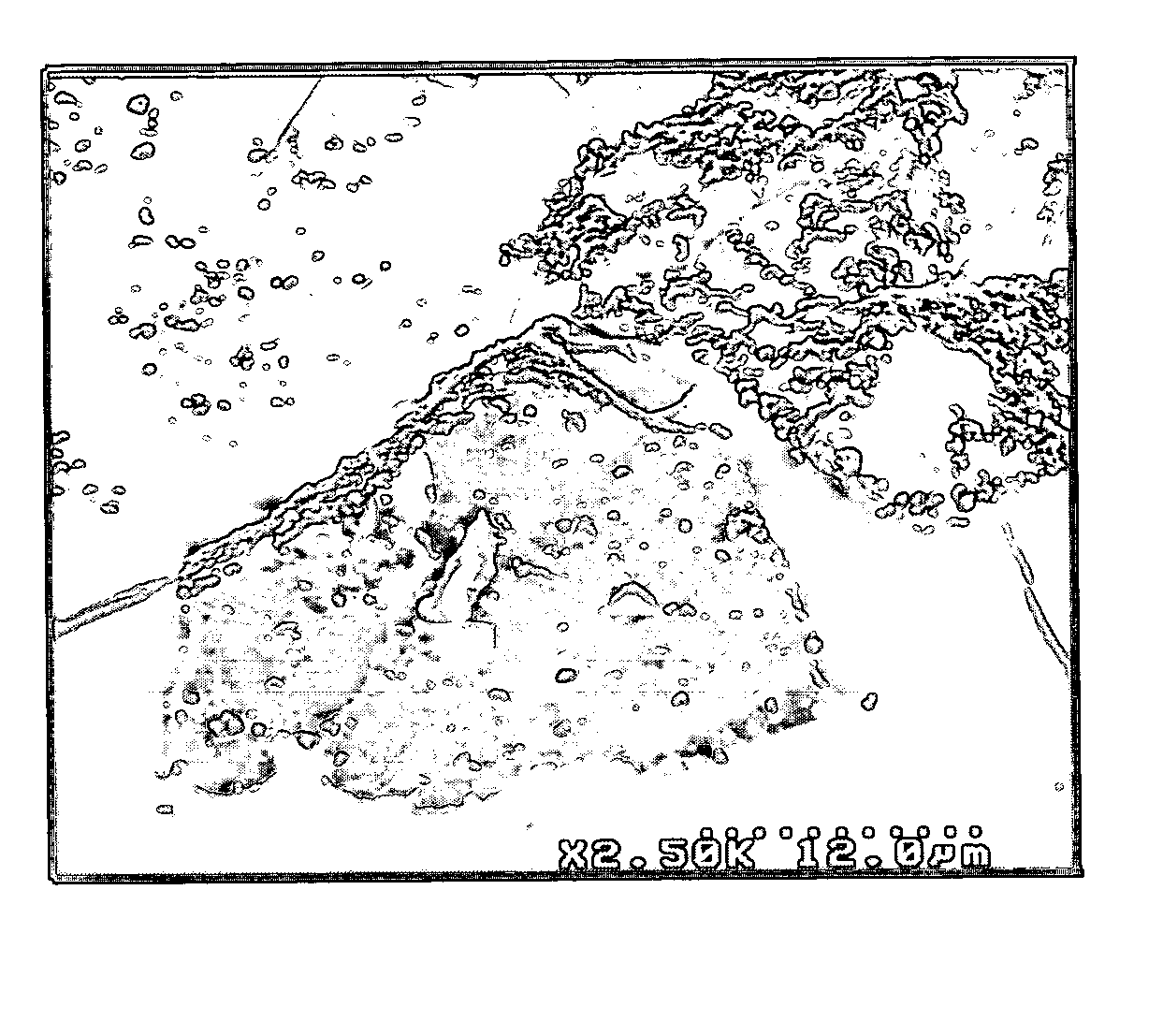

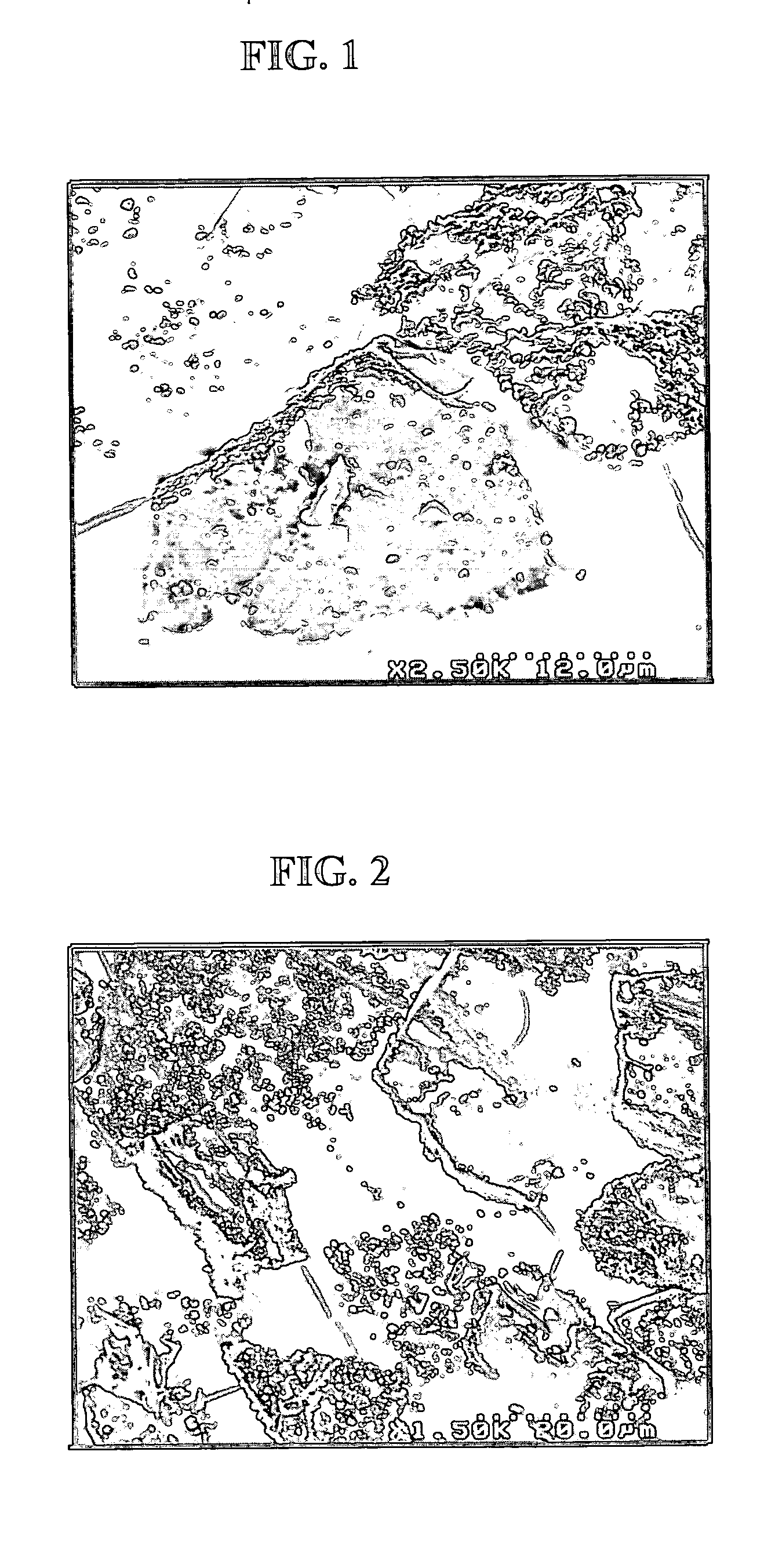

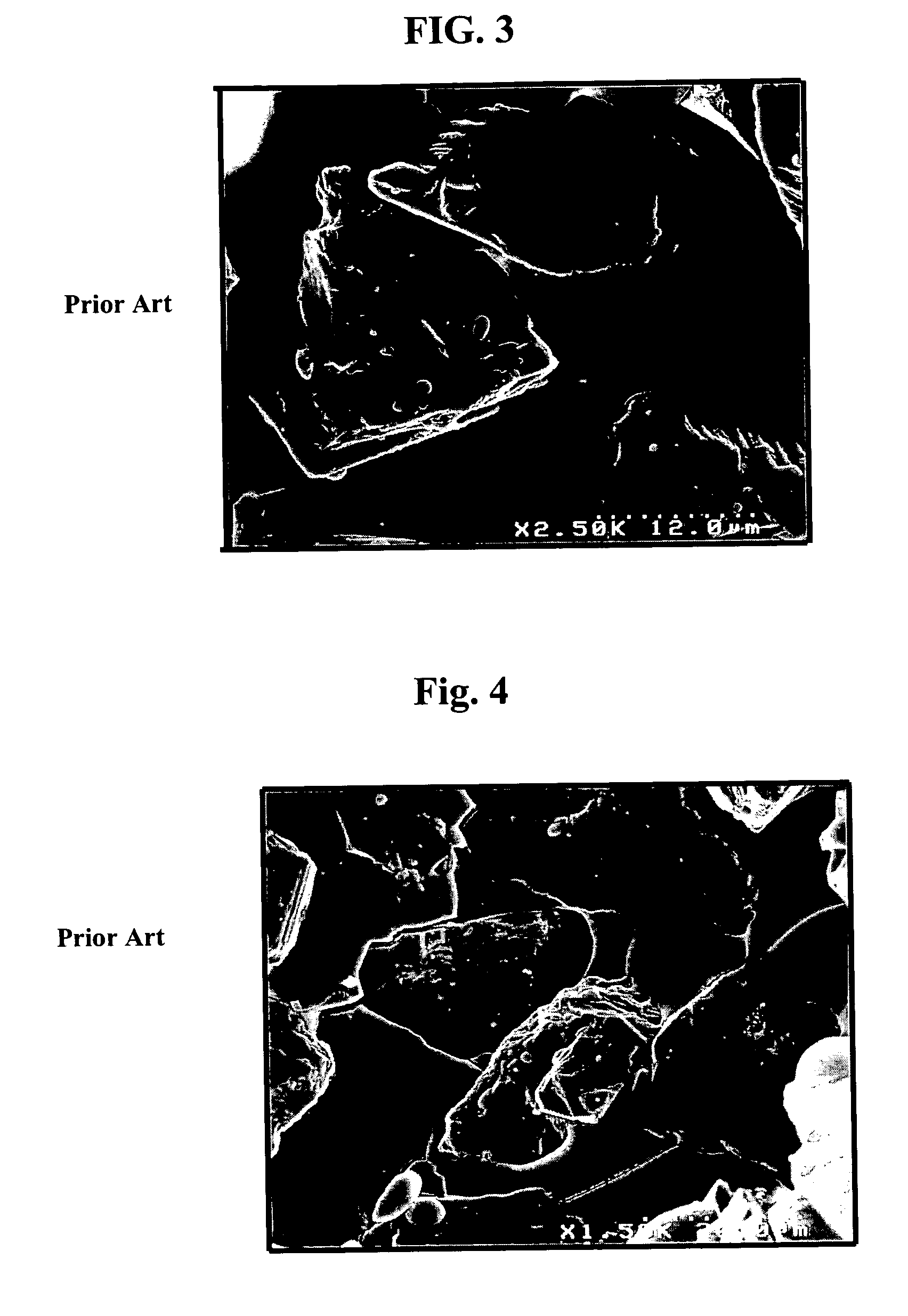

[0053] As seen in FIGS. 1-4, a coating embodiment of the present invention wherein titanium-coated diamond particles are distributed within a glass matrix is compared to prior art coatings wherein uncoated diamond particles are contained within a glass matrix. FIGS. 1 and 2 represent a wear-resistant coating embodiment of the present invention wherein diamond particles of about 30 μm to about 40 μm are coated with titanium and deposited within a glass matrix material to form a wear-resistant coating. As illustrated by FIGS. 1 and 2, the glass matrix “wets” the surface of the coated diamond particles, as illustrated by the “textured” appearance of the coated particles within the glass matrix. This wetting in FIGS. 1 and 2 leads to better diamond particle adhesion and retention within the matrix. Thus an improved wear-resistant coating comprising coated diamond particles within a matrix material m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com