Vertical array wind turbine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

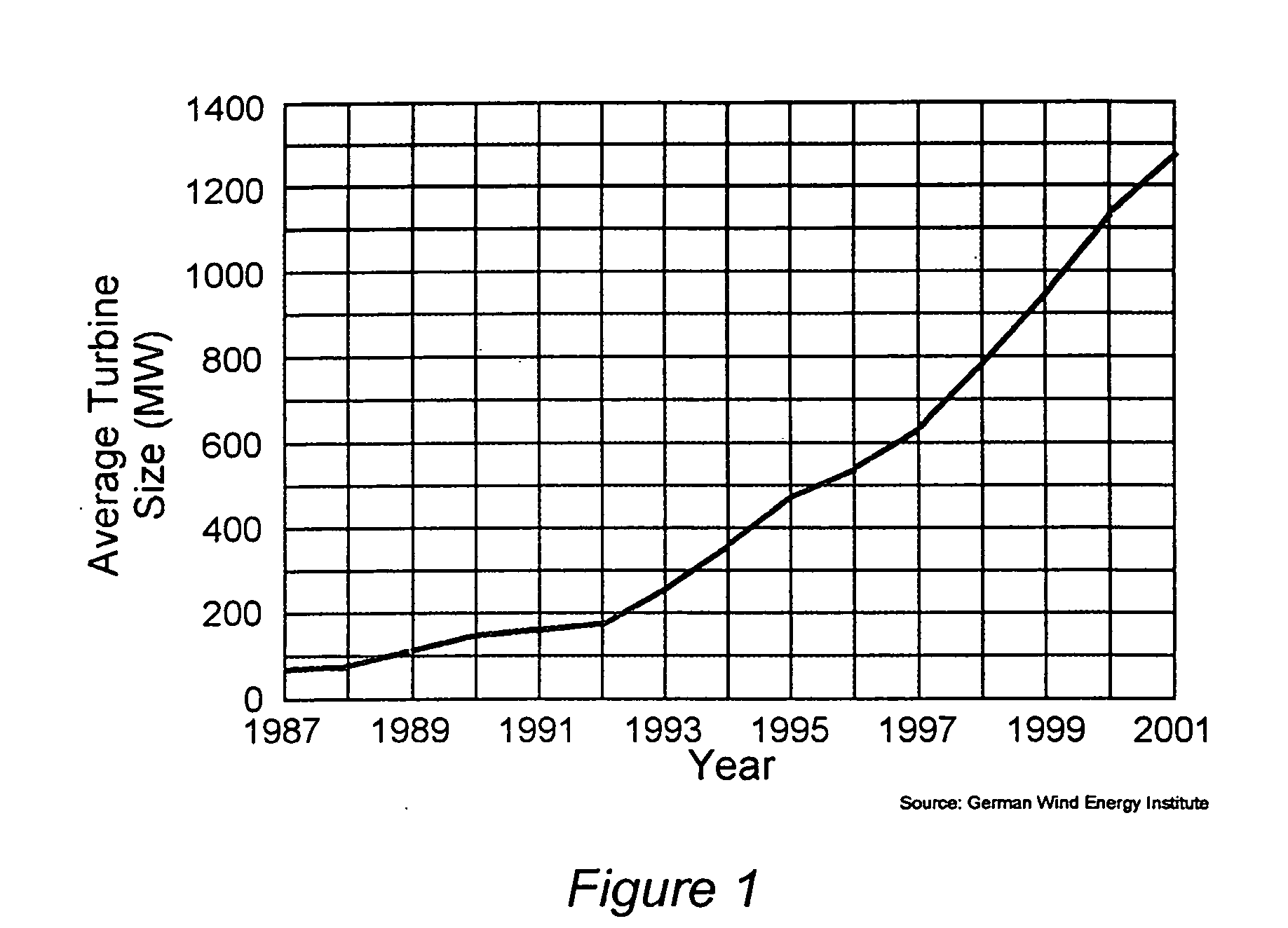

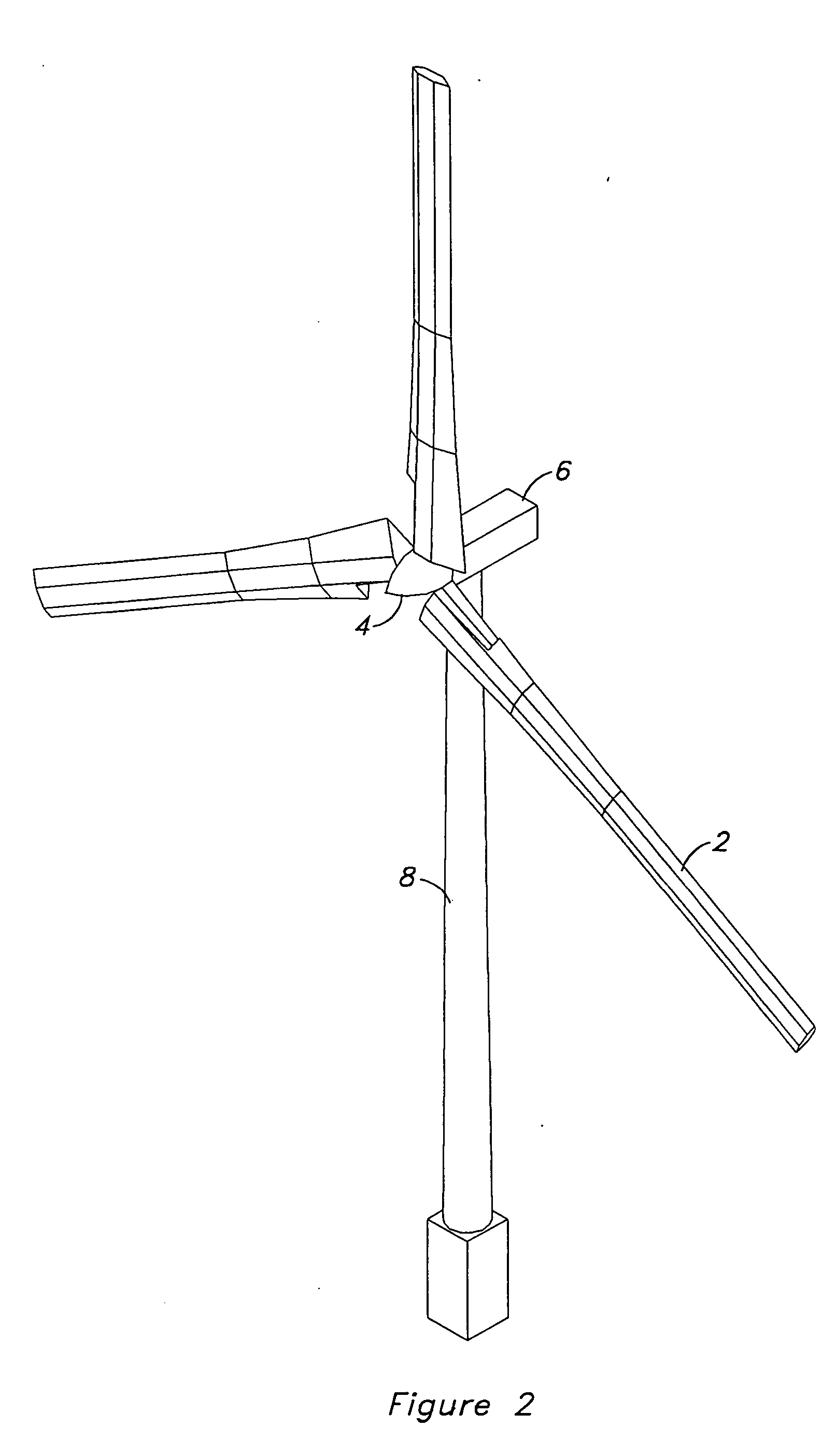

[0037]FIG. 2 shows a wind turbine according to the prior art. The turbine includes a set of blades 2, a hub 4 a nacelle 6, and a tower 8. Prior art turbines can include any number of blades 2, although three blades is the most common configuration. The blades 2 can be oriented upwind or downwind of the tower 8, although upwind is the most common and most efficient configuration. A yaw system is provided to allow rotation between the nacelle 6 and the tower 8 so that the nacelle 6 can be aligned with the wind direction. The rotor diameter is defined as two times the length of a blade 2 plus the diameter of the hub 4. Typical rotor diameters for commercially available wind turbines have grown significantly over the past 15 to 20 years. In the mid 1980s, state of the art commercially-available wind turbines had rotor diameters of approximately 20 meters and power ratings of approximately 100 kW. In 2001, the average size of wind turbines installed in Germany was 1284 kW, and the US mar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com