Readily donned, powder-free elastomeric article

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

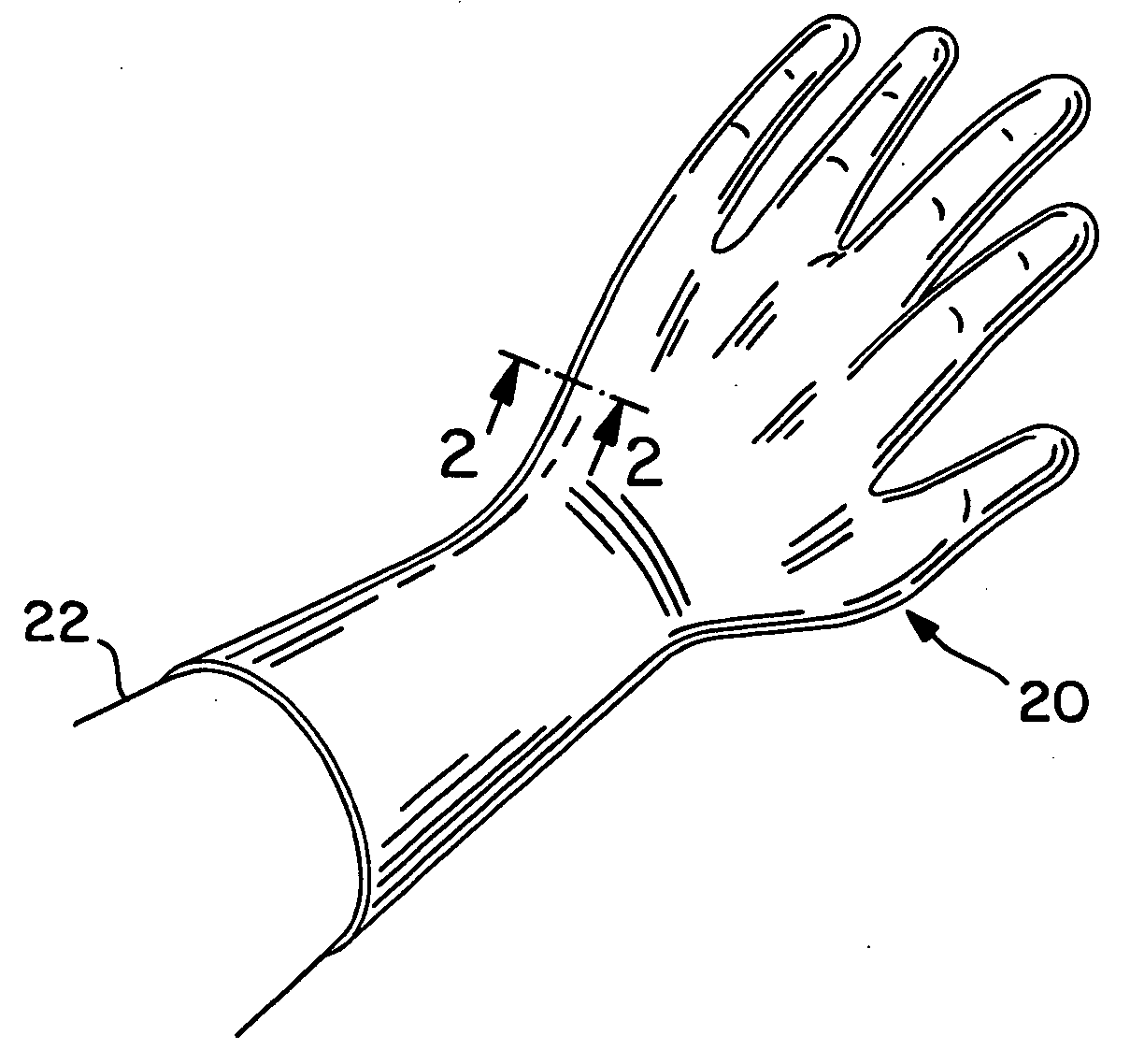

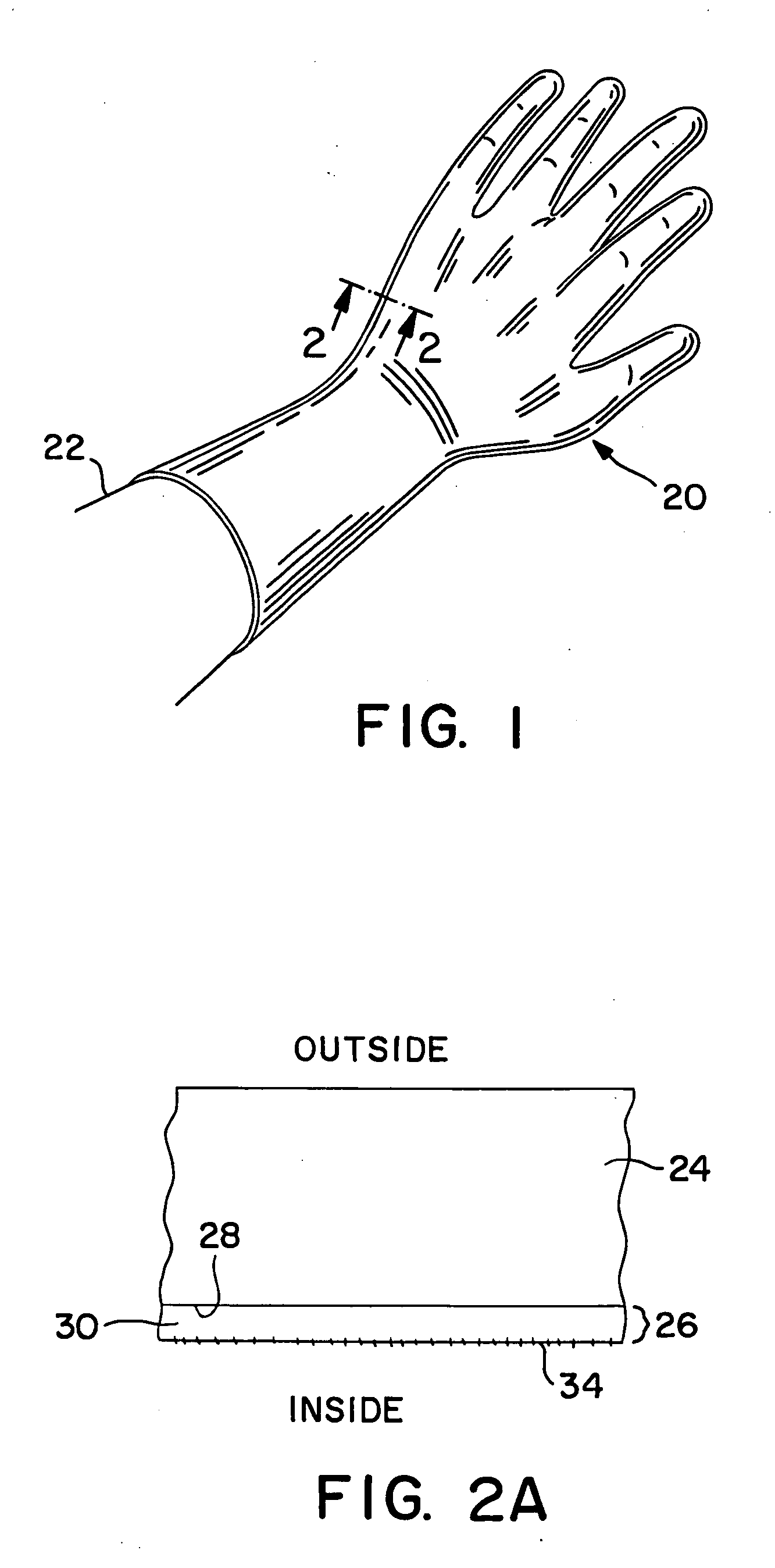

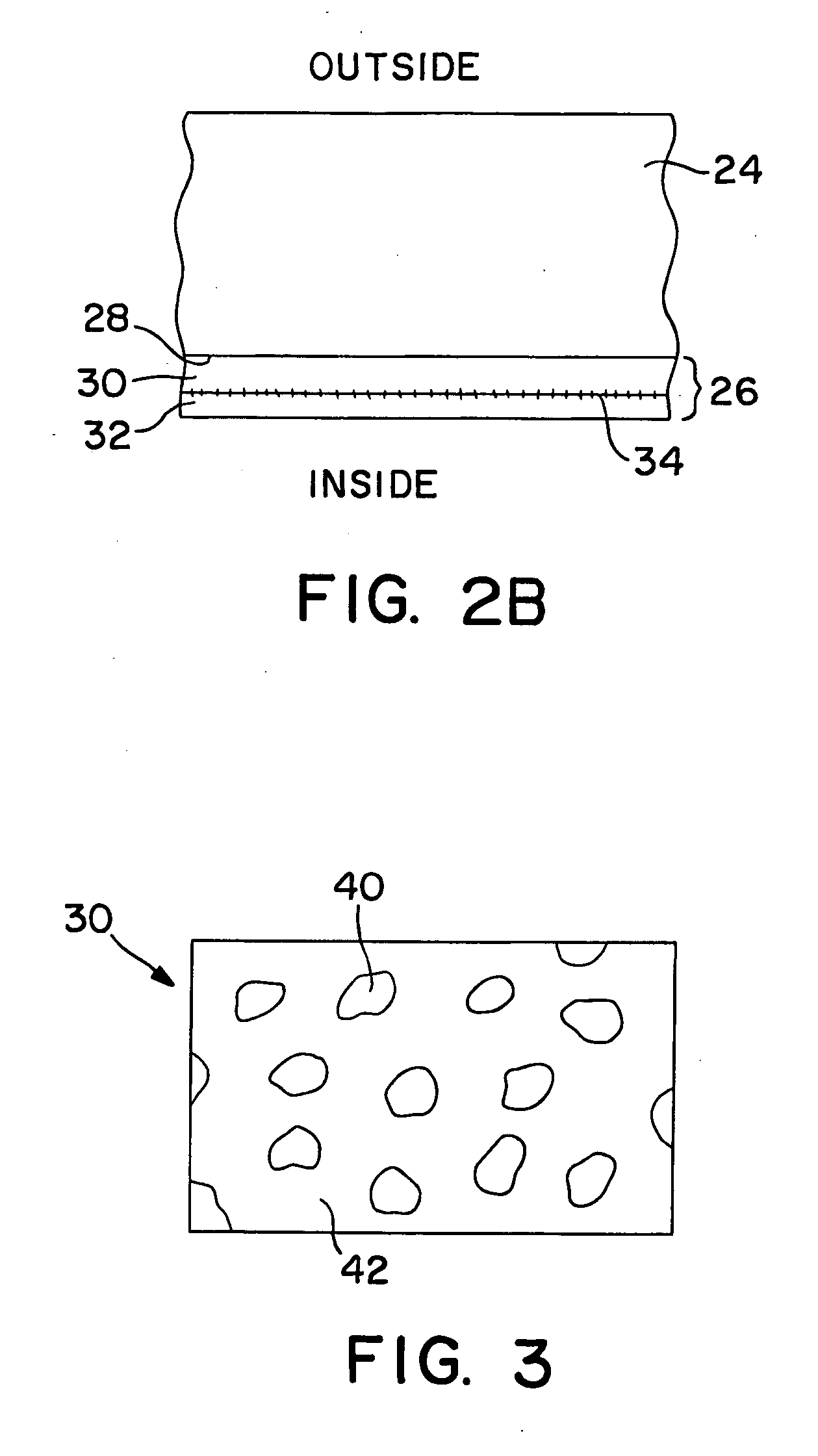

Image

Examples

example 1

[0037] A Glove was dip formed from S-EB-S block copolymer, as described above. While still on the former but after drying, the glove was dipped into a 4 percent by weight solution of VectorR 511 S-I-S block copolymer in toluene. The S-I-S solution on the glove was air dried to remove the solvent. The glove was dipped into a solution of 4905 grams of water, 70 grams of sodium hypochlorite (14 percent by weight in water), and sufficient hydrochloric acid to produce a solution having a pH of 2, for a period of about 15 minutes, and dried. The glove was then stripped from the former. It showed good dry donning characteristics without the use of any powder.

example 2

[0038] Example 1 was repeated, except that the chlorinating solution contained 4050 grams of water, 700 grams of sodium hypochlorite, and 250. grams of hydrochloric acid, and the immersion time was 1 minute. After drying and removing from the form, the glove showed good dry donning characteristics without the use of any powder.

example 3

[0039] Example 1 was repeated for a batch of 20 gloves, for the dip forming and S-I-S coating steps (but not for the chlorinating step, which was accomplished by a different approach as described subsequently). Before stripping the gloves from their forms, dry cornstarch powder was applied. The powdered gloves were loaded into a washing machine with 11.4 grams of Surfynol TGR mixed into 38 liters of water. The gloves were run in the washing machine for 15 minutes at low agitation and removed from the washer. The washer was then filled with a solution of 38 liters of clean water, 1994 grams of 7 percent chlorox bleach (2300 ppm chlorine), and 460 milliliters of 6N sulfuric acid, the solution having a pH of 2.2 at 18.9° C. The wet gloves were added with the S-I-S coating on the outside of the gloves and agitated for 15 minutes. The measured pH of the solution rose to 2.41 in 5 minutes, 2.64 after 10 minutes, and 2.68 after 15 minutes. After 15 minutes, the solution was neutralized wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Elongation | aaaaa | aaaaa |

| Elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com