Preparation of defect-free polyacrylamide electrophoresis gels in plastic cassettes

a technology of polyacrylamide and electrophoresis gel, which is applied in the field of polyacrylamide gels, can solve the problems of apparent solute band distortion and band distortion, and achieve the effect of uniform pore siz

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

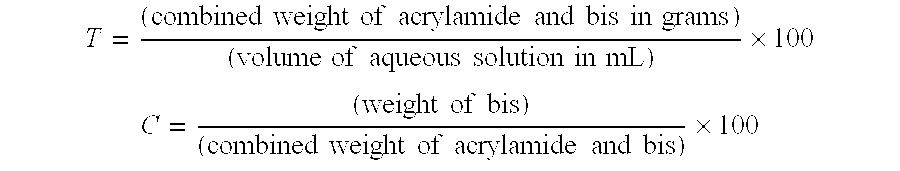

A gel-forming solution was prepared by combining the following components in an aqueous solution in the concentrations indicated: acrylamide / N,N′-methylene-bisacrylamide (T 12%, C=2.67%) 0.375 M tris-HCl (tris(hydroxymethyl)aminomethane hydrochloride), pH 8.6 0.067% TEMED 0.05% ammonium persulfate 6 mM sodium sulfite

The acrylamide / bisacrylamide mixture in the solution was allowed to polymerize at room temperature (approximately 20° C.) for 30-60 minutes to form a gel ready for electrophoresis.

example 2

The following solutions were prepared for use in forming resolving and stacking gels for a gel cassette constructed with one glass plate and one acrylic plastic plate. All percents are by weight unless otherwise indicated, and all solutions are aqueous solutions.

TABLE IResolving Gel:deionized H2O34.5mL1.5 M Tris-HCl, pH 8.825.0mL30% (37.5:1)40.0mLacrylamide / bisacrylamide10% ammonium persulfate500μLTEMED50μLStacking Gel:deionized H2O6.2mL1.5 M Tris-HCl, pH 6.82.5mL30% (37.5:1)1.3mLacrylamide / bisacrylamide10% ammonium persulfate50μLTEMED10μL

A stock solution of sodium sulfite (1 M aqueous) was also prepared, and added to the resolving and stacking gel solutions in different levels as follows: (1) No sodium sulfite added to either gel (2) 57.1 μL of stock solution added to both gel solutions to a final sodium sulfite concentration of 72.02 μg / mL (0.571 mM) in each solution (3) 571.4 μL of stock solution added to both gel solutions to a final sodium sulfite concentration of 720.2 ...

example 3

The following solutions were prepared for use as resolving and stacking gels for a gel cassette formed from two plates of uncoated polystyrene-acrylonitrile copolymer (SAN 880B TYRIL®, The Dow Chemical Company, Midland, Mich., USA). All percents are by weight unless otherwise indicated, and all solutions are aqueous solutions.

TABLE IIResolving Gel:deionized H2O34.5mL1.5 M Tris-HCl, pH 8.825.0mL30% (37.5:1)40.0mLacrylamide / bisacrylamide10% ammonium persulfate500μLTEMED50μLStacking Gel:deionized H2O6.2mL1.5 M Tris-HCl, pH 6.82.5mL30% (37.5:1)1.3mLacrylamide / bisacrylamide10% ammonium persulfate50μLTEMED10μL

A stock solution of 1 M aqueous sodium sulfite was also prepared and added to the resolving and stacking gel solutions in different levels as follows: (1) No sodium sulfite added to either gel (2) 57.1 μL of stock solution added to both gel solutions to a final sodium sulfite concentration of 72.02 μg / mL (0.571 mM) in each solution (3) 571.4 μL of stock solution added to both ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| weight ratio | aaaaa | aaaaa |

| transparent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com