Ferroelectric thin film, method of manufacturing the same, ferroelectric memory device and ferroelectric piezoelectric device

a technology of ferroelectric memory and ferroelectric piezoelectric device, which is applied in the direction of basic electric elements, semiconductor devices, electrical apparatus, etc., can solve the problems of not being able to secure the b>10/b>-year guarantee generally required for semiconductors, and not being put into commercial use as ferroelectric memory devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

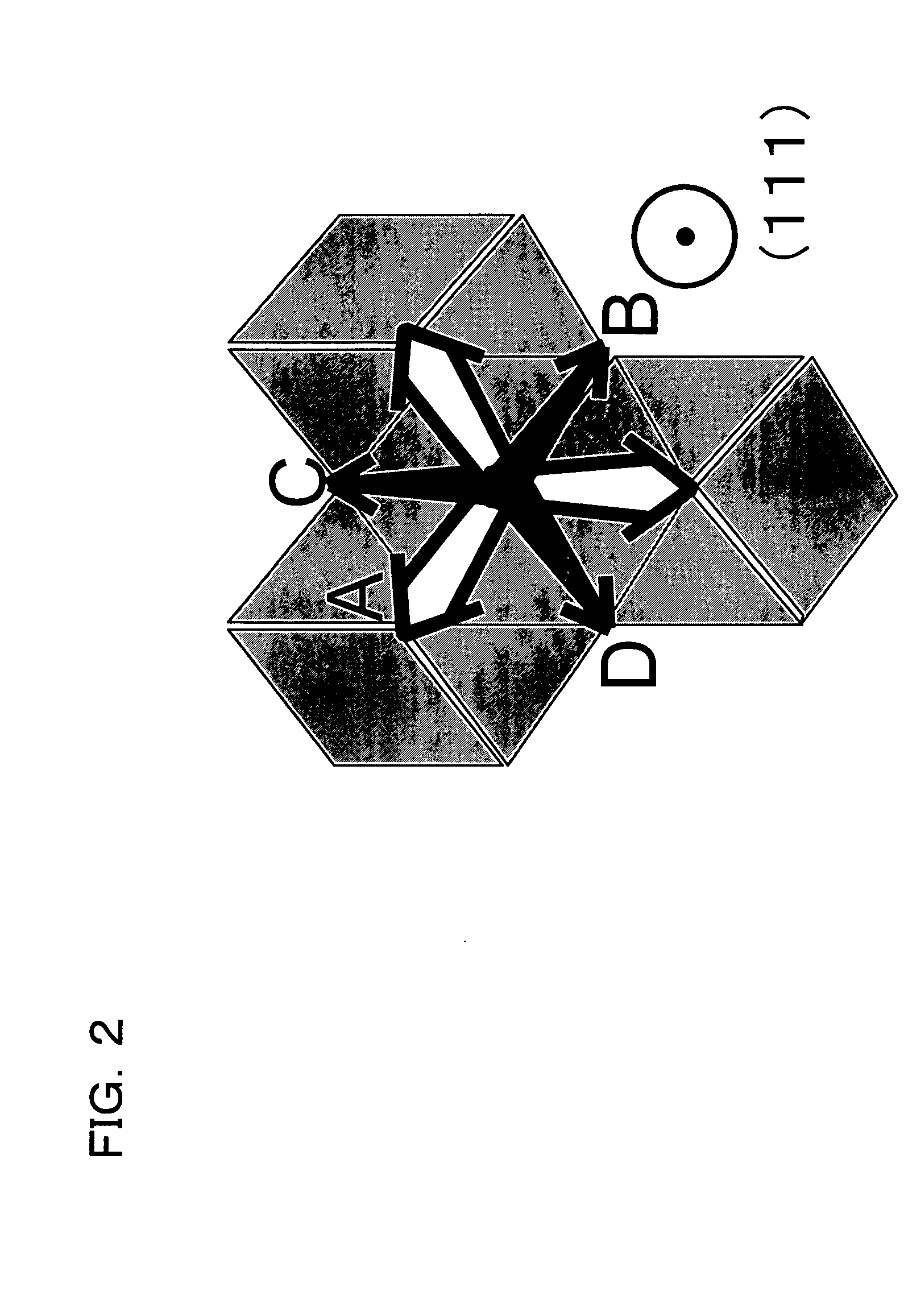

[0053]FIG. 3 shows an orientation plane suitable for device applications determined for PZT having a tetragonal structure. In FIG. 3, bulk values are used as the lattice constant, polarization axis direction (90° domain necessarily exists with the 180° domain), and polarization. The state in which the polarization axes infinitely exist in a rotated state in the film plane is shown by using six directions for convenience of illustration. As candidates for the orientation planes, orientation planes with high existence probability selected from JCPDS were used. In FIG. 3, the multiplicity means the degree in which the polarization axes completely overlap when determining the orientation plane suitable for device applications using the above parameters. In the case where two or more polarization axes remain, the higher the multiplicity, the higher the existence probability. The polarization axis with higher multiplicity effectively contributes to polarization with higher probability.

[0...

example 2

[0060] In this example, a PbZr0.4Ti0.6O3 ferroelectric thin film was formed.

[0061] A conventional method uses a solution containing Pb in an excess amount of about 20%. This aims at preventing volatilization of Pb and reducing the crystallization temperature. However, since the state of the excess Pb in the resulting thin film is unknown, the amount of excess Pb should be limited to the minimum.

[0062] A PbZr0.4Ti0.6O3 thin film with a thickness of 200 nm was formed according to a flow shown in FIG. 8 by using 10 wt % sol-gel solutions for forming PbZr0.4Ti0.6O3 (solvent: n-butanol) in which the amount of excess Pb was 0%, 5%, 10%, 15%, and 20%, and further adding 1 mol % of a 10 wt % sol-gel solution for forming PbSiO3 (solvent: n-butanol). FIG. 9 shows XRD patterns and surface morphology of the resulting thin films.

[0063] About 20% excess Pb is necessary in a conventional method. However, it was found that crystallization sufficiently proceeds with the addition of 5% excess Pb. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com