Production method for sintered component made of stainless steel with high corrosion resistance

a technology of stainless steel and production method, which is applied in the field of production method of sintered components made of stainless steel with high corrosion resistance, can solve the problems that the perovskite composite oxide powder is not easily agglomerated, and achieve the effects of high corrosion resistance, increased corrosion resistance, and high corrosion resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

(Practical Example 1)

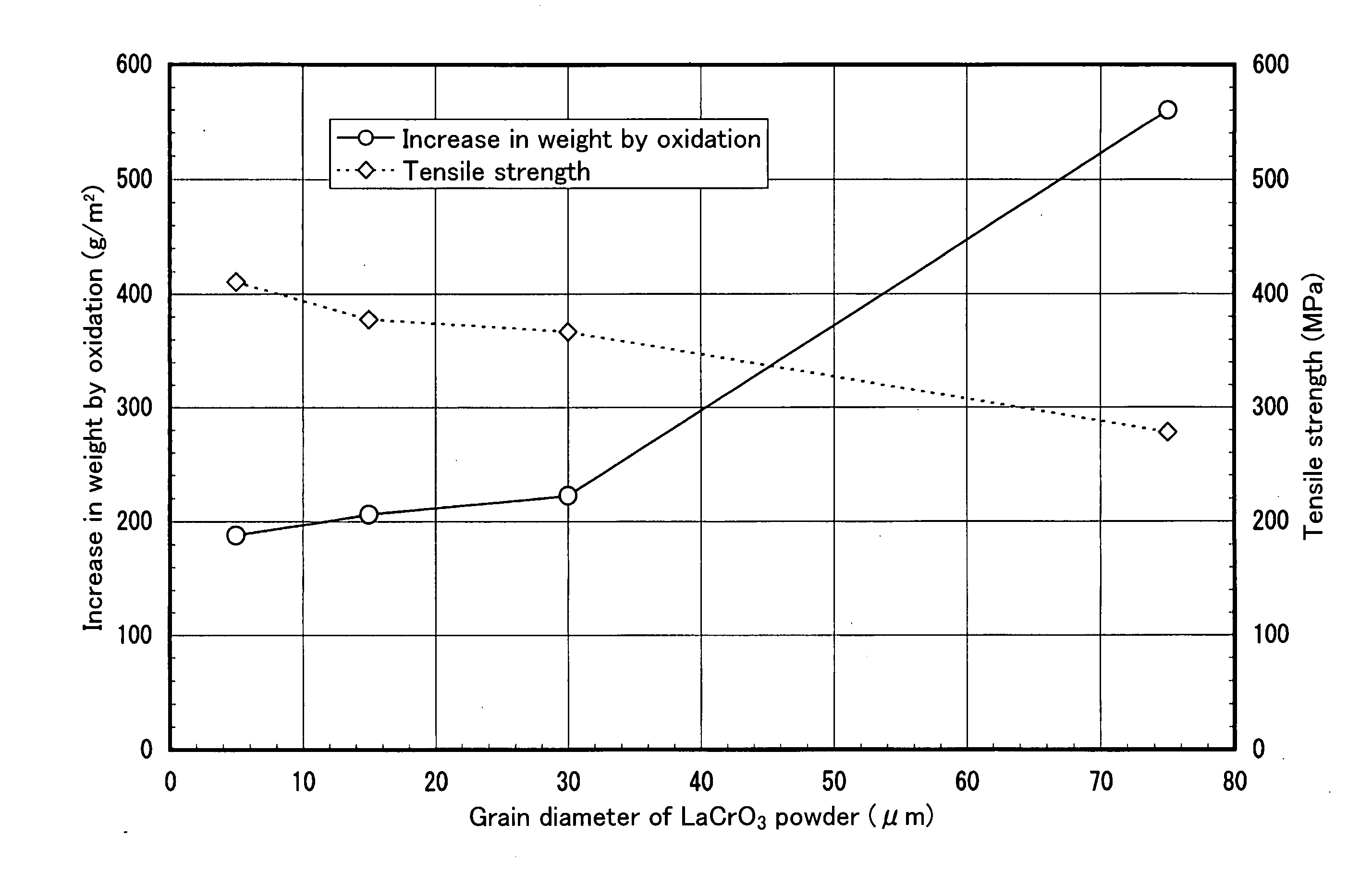

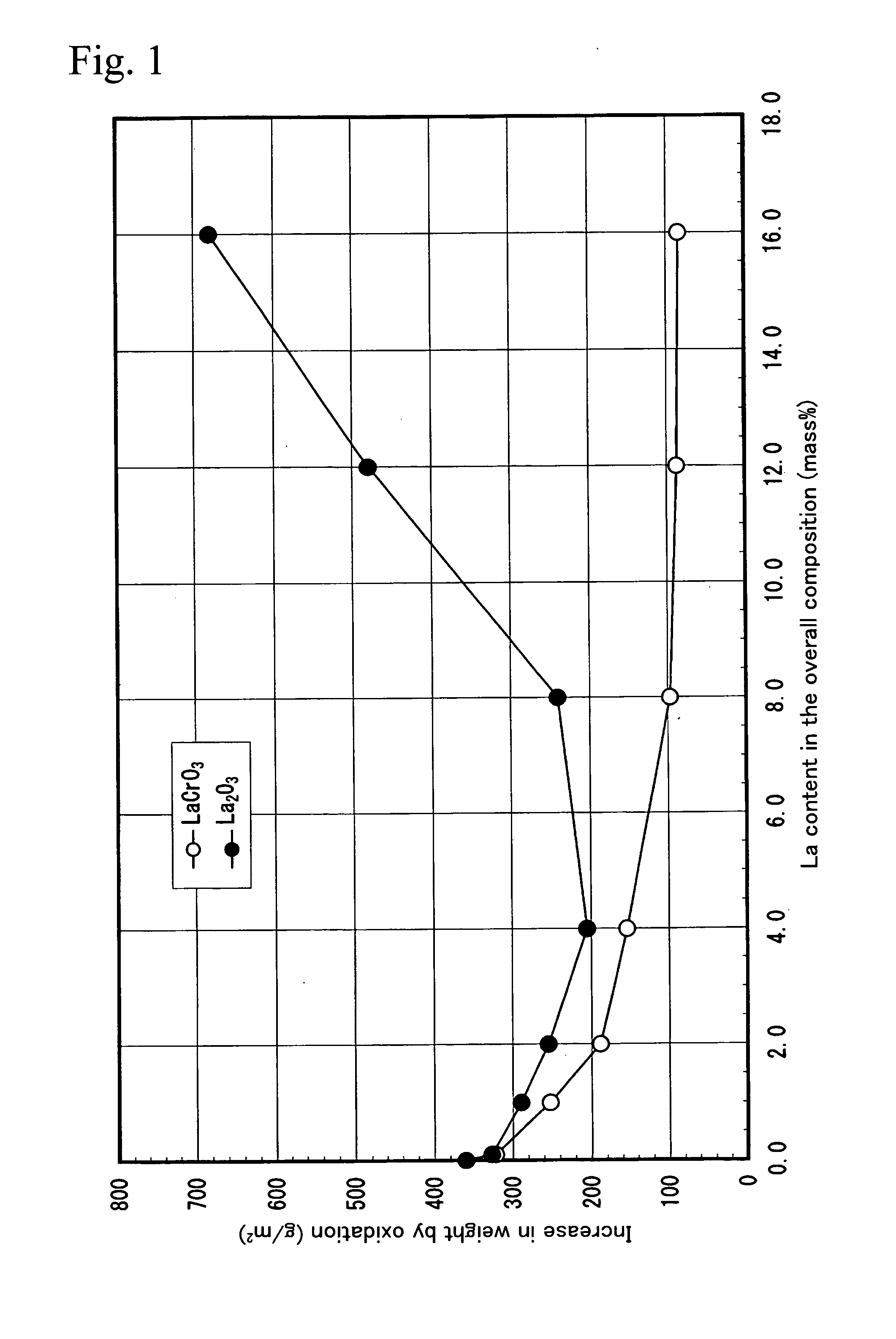

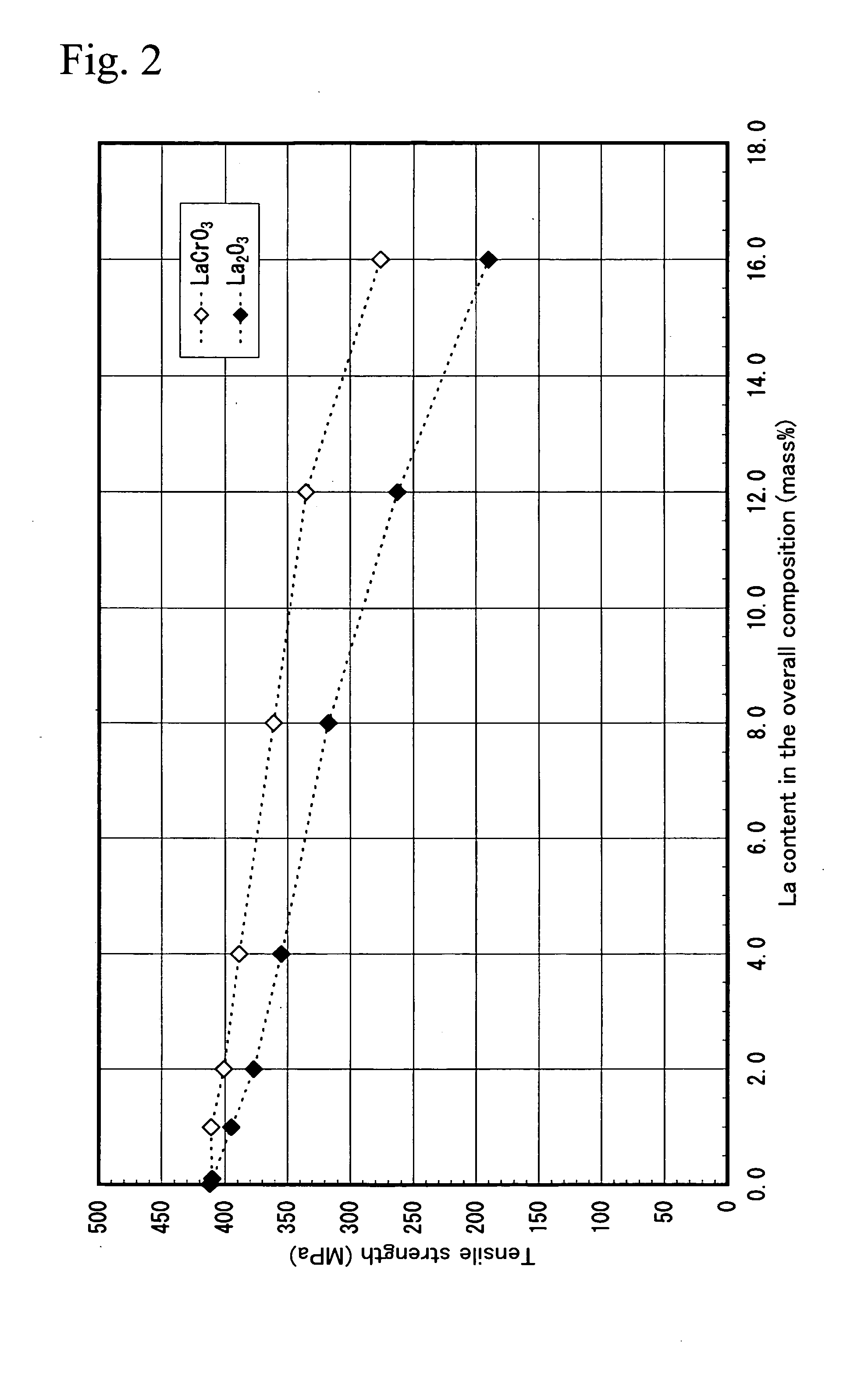

[0030] SUS310 powder which was defined by the JIS (Japan Industrial Standards) and was equal to 310 defined by the AISI (American Iron and Steel Institute) was prepared as a stainless steel powder forming a matrix, and LaCrO3 powder and La2O3 powder which had average grain diameters of 5 μm were prepared as a rare earth-oxygen composite powder. These powders were dispensed at a rate shown in Table 1, and were mixed, whereby a raw powder was obtained. The raw powder was compacted into a cylindrical shape (diameter: 10 mm, height: 10 mm) and to a square block having a square cross-section (width: 60 mm, depth: 10 mm, height: 10 mm), in order to set the green density to be 6.7 g / cm3, obtained green compacts were sintered in a hydrogen atmosphere at a sintering temperature of 1250° C. for 1 hour, whereby samples shown by sample Nos. 1 to 12 were produced.

[0031] In the samples having the cylindrical shape, each sample was set in a crucible made of aluminum per test ...

example 2

(Practical Example 2)

[0038] LaCrO3 powder and La2O3 powder used in the Practical Example 1 were added to the stainless steel powder shown in the Table 2, in order to set the La content in the overall composition to 2 mass %, whereby a mixed raw powder was obtained. Test pieces were produced by using the raw powder in the same process of Practical Example 1, and oxidation testing was performed. The results are also shown in Table 2 and are shown in FIG. 3 as a graph. Additionally, SUS304 (JIS) is a steel type equal to 304 defined by the AISI, and SUS430 (JIS) is a steel type equal to 430 defined by the AISI.

TABLE 2rare earthcomposition rate (mass %)elementincreasestainless steelrare earth-oxygencontent inin weightpowdercomposite powderthe overallbysamplesteeladditionadditioncompositionoxidationnumbertypeamounttypeamount(mass %)(g / m2)04SUS310balanceLaCrO33.442.0018811SUS310balanceLa2O32.352.0025416SUS304balanceLaCrO33.442.0033517SUS304balanceLa2O34.692.0040718SUS430balanceLaCrO33.44...

example 3

(Practical Example 3)

[0040] Perovskite composite oxide powder having an average grain diameter of 5 μm shown in Table 3 was added to the stainless steel powder (SUS310 powder), in order to set rare earth metal element content in the overall composition to 2 mass %, and these powders were mixed, whereby a mixed raw powder was obtained. Test pieces were produced by using the raw powder in the same process of Practical Example 1, and oxidation testing was performed. The results are also shown in Table 3 and are shown in FIG. 4 as a graph.

TABLE 3rare earthcomposition rate (mass %)elementincreasestainless steelrare earth-oxygencontent inin weightpowdercomposite powderthe overallbysamplesteeladditionadditioncompositionoxidationnumbertypeamounttypeamount(mass %)(g / m2)04SUS310balanceLaCrO33.442.0018811SUS310balanceYCrO34.252.0019516SUS304balanceCeCrO33.432.0019617SUS304balanceLaFeO33.502.0021018SUS430balanceLaNiO33.532.0019919SUS430balanceLa2O32.352.00254

[0041] As shown in the Table 3 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grain diameter | aaaaa | aaaaa |

| grain diameters | aaaaa | aaaaa |

| green density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com