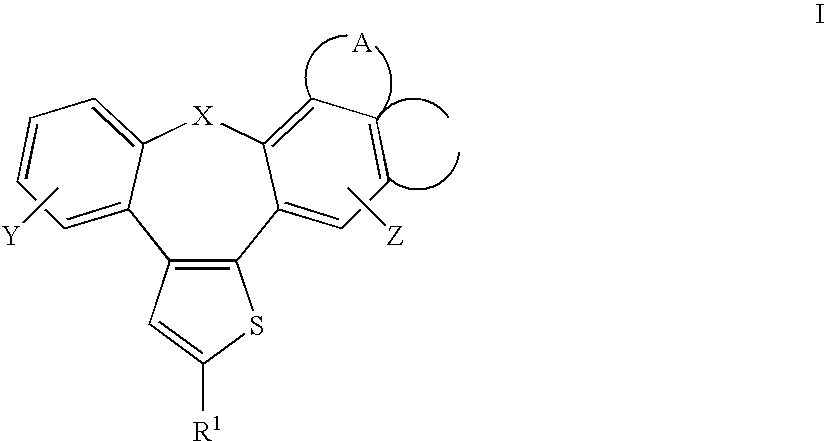

1-or 3-thia-benznaphthoazulenes as inhibitors of tumour necrosis factor production and intermediates for the preparation thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

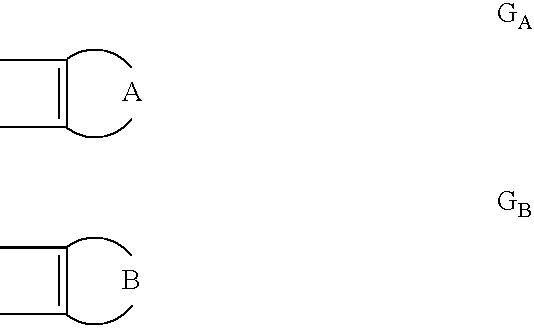

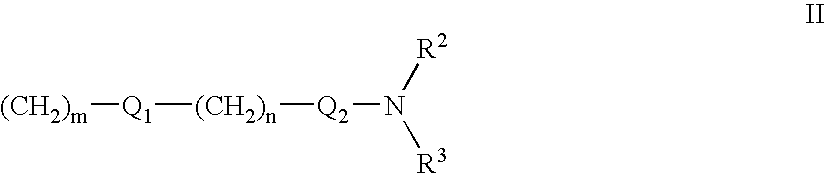

Method used

Image

Examples

example 1

8-Oxa-1-thia-benzo[e]naphtho[3,2-h]azulene-2-carboxylic acid ethyl ester (48; Table 1)

[0097] Ethyl-2-mercaptoacetate (0.005 mole) and triethyl amine (1.0 ml) were added to a pyridine solution of the compound 41 (0.005 mole in 10 ml) and the mixture was refluxed under stirring for 3 hours. Then pyridine was removed under reduced pressure. Water and ethyl acetate were added to the residue, the layers were separated and the aqueous layer was twice more extracted with ethyl acetate. The organic layer was dried on sodium sulfate and evaporated. There remained a crude product, which was purified by recrystallization or column chromatography to give a pure product in the form of a white solid.

[0098] According to the above process, starting from compounds 42-47 there were prepared and isolated: [0099] 1,8-dithia-benzo[e]naphtho[3,2-h]azulene-2-carboxylic acid ethyl ester; [0100] 3,10-dithia-benzo[e]naphtho[1,2-h]azulene-2-carboxylic acid ethyl ester; [0101] 10-oxa-3-thia-benzo[e]naphtho[1...

example 2

(8-Oxa-1-thia-benzo[e]naphtho[3,2-h]azulene-2-yl)-methanol (55; Table 1)

[0105] An ether solution of ester 48 (1.5 mmole in 20 ml) was added dropwise to a suspension of LiAIH4 in ether (5.0 mmole in 10 ml). The reaction mixture was stirred at room temperature for 2 hours. After the completion of reaction the excess of LiAIH4 was decomposed by addition of ether and water. The obtained precipitate was filtered off and the filtrate was evaporated under reduced pressure. A crude product was purified by recrystallization to obtain a pure product in the form of white crystals.

[0106] According to the above process, starting from compounds 49-54 there were prepared and isolated: [0107] (1,8-dithia-benzo[e]naphtho[3,2-h]azulene-2-yl)-methanol; [0108] (3,10-dithia-benzo[e]naphtho[1,2-h]azulene-2-yl) -methanol; [0109] (10-oxa-3-thia-benzo[e]naphtho[1,2-h]azulene-2-yl)-methanol; [0110] (11-methoxy-8-oxa-1-thia-benzo[e]naphtho[3,2-h]azulene-2-yl)-methanol; [0111] (6,7,8,9-tetrahydro-10-oxa-3-th...

example 3

a) Dimethyl-[2-(8-oxa-1-thia-benzo[e]naphtho[3,2-h]azulene-2-ylmethoxy)-ethyl]-amine

[0114] To a solution of 2-dimethylaminoethyl chloride hydrochloride (3.0 mmole) in 50% sodium hydroxide (5 ml), a catalytic amount of benzyltriethylammonium chloride and a solution of alcohol 55 (0.3 mmole) in toluene (5 ml) were added. The reaction mixture was heated under reflux and vigorous stirring for 4 hours. Then it was cooled to room temperature, diluted with water and extracted with dichloromethane. After purifying by column chromatography, a yellow oily product was isolated.

[0115]1H NMR (ppm, CDCl3): 2.31 (s, 6H); 2.60 (t, 2H); 3.68 (t, 2H); 4.78 (s, 2H); 7.18-7.50 (m, 7H); 7.73 (s, 1H); 7.80 (m, 2H); 7.90 (s, 1H); MS (m / z): 402 (MH+).

b) Dimethyl-[3-(8-oxa-1-thia-benzo[e]naphtho[3,2-h]azulene-2-ylmethoxy)-propyl]-amine

[0116] By the reaction of alcohol 55 (0.2 mmole) and 3-dimethylaminopropyl chloride hydrochloride (2.0 mmole), a yellow oily product was obtained.

[0117]1H NMR (ppm, CDCl3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| humidity | aaaaa | aaaaa |

| humidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com