Method for fabrication of semiconductor device

a semiconductor device and fabrication method technology, applied in semiconductor devices, semiconductor/solid-state device details, electrical equipment, etc., can solve the problems of increasing the cost of mask sets required for each new process technology, increasing the cost of product development, and reducing manufacturing flexibility. , to achieve the effect of saving mask costs, saving silicon, and increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0100] The present invention is now described with reference to FIGS. 1-25, it being appreciated that the figures illustrate the subjects matter not to scale or to measure.

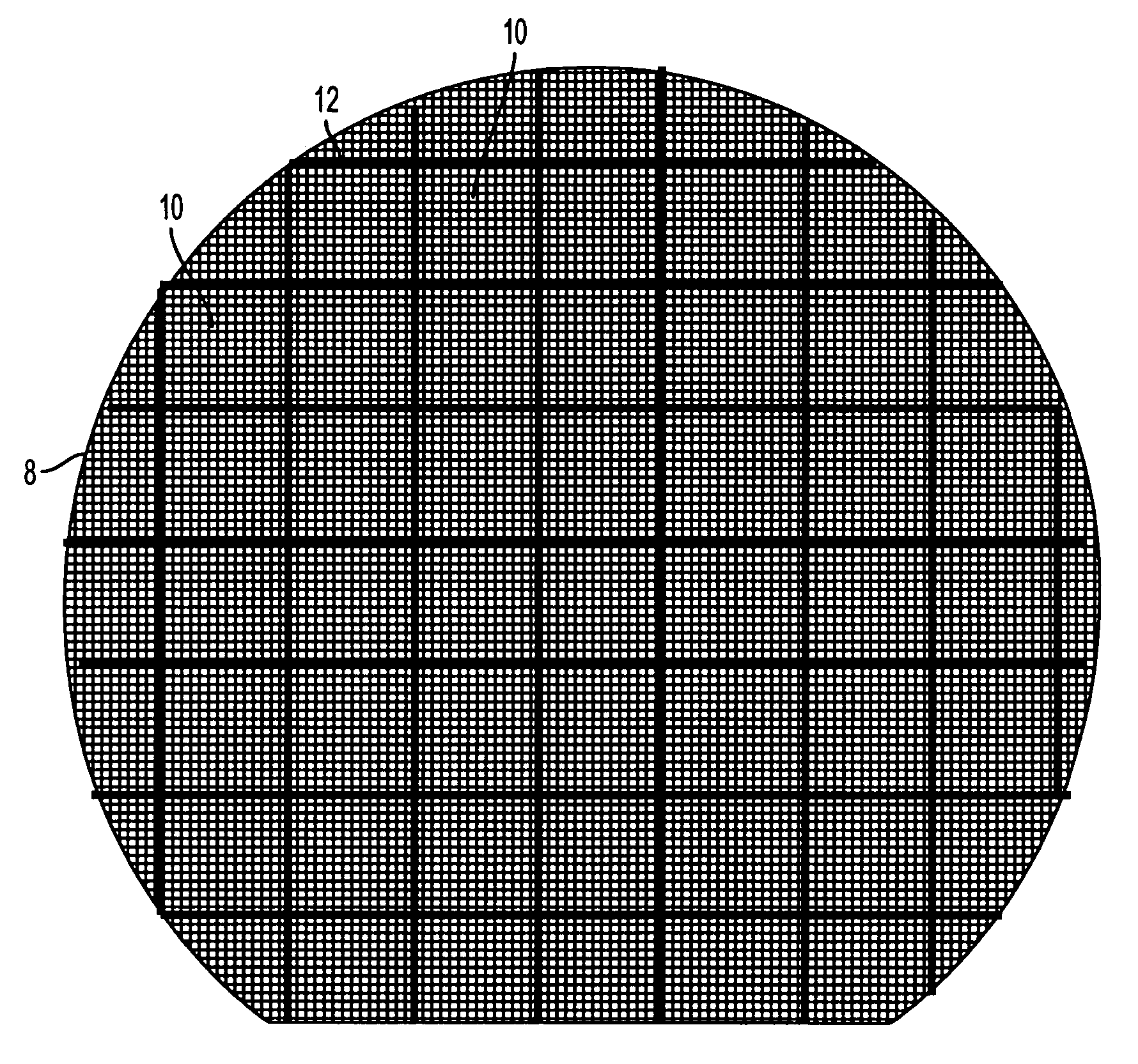

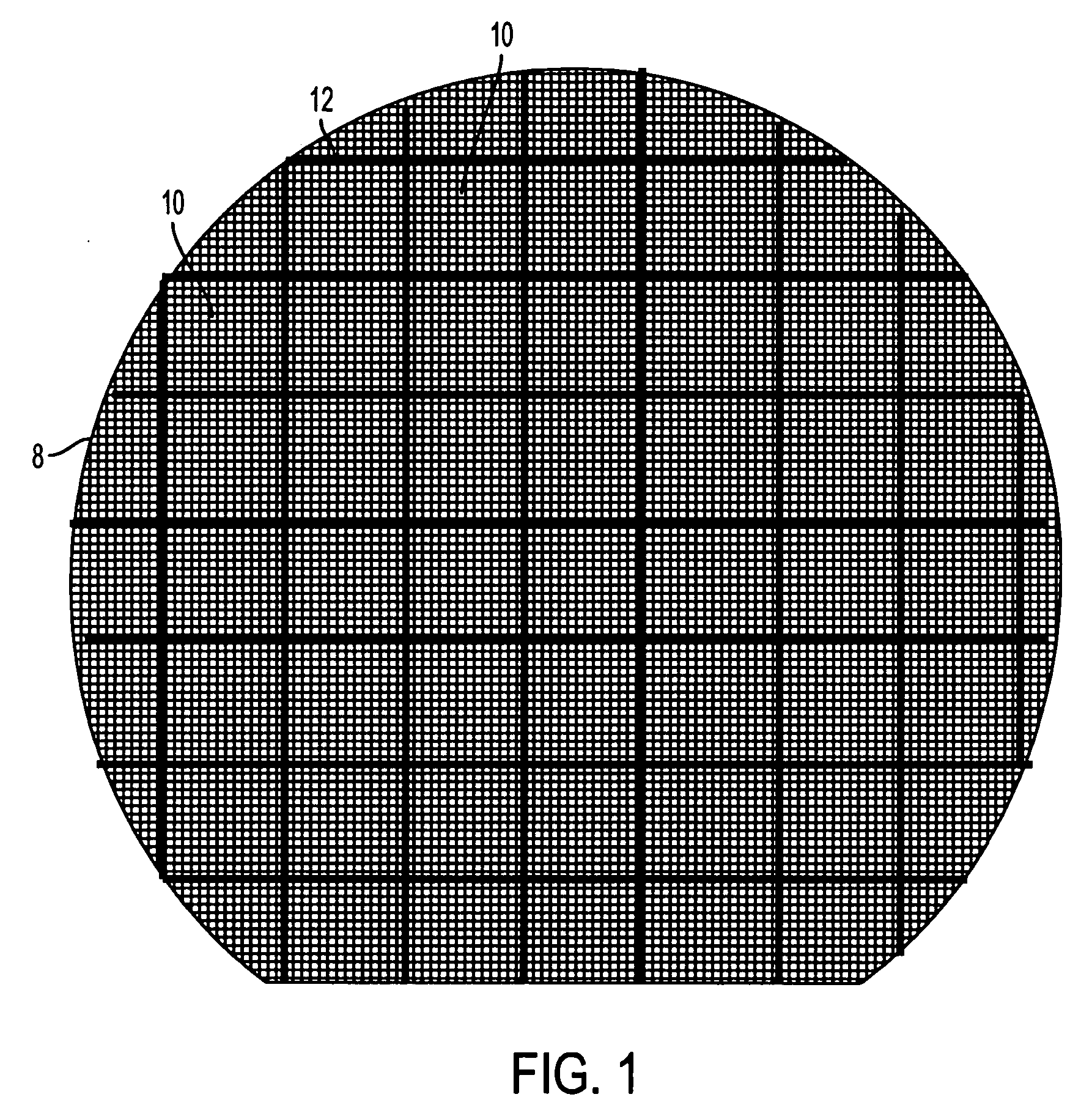

[0101] The current method of semiconductor fabrication is on lithography step for each layer. The dominating lithography technique of submicron process is called step and repeat. The layer pattern will be drawn into mask also called reticle. Such reticle may be projected over an area of about 20 mm×20 mm by the lithography tool called Stepper. Then the Stepper steps the wafer so the reticle would be projecting the same pattern on area next to it and so for. FIG. 1 illustrates a wafer 8 with marks 12 of reticle projections 10. With an 8-inch wafer, over 50 copies of the reticle will be typically stepped on one such wafer.

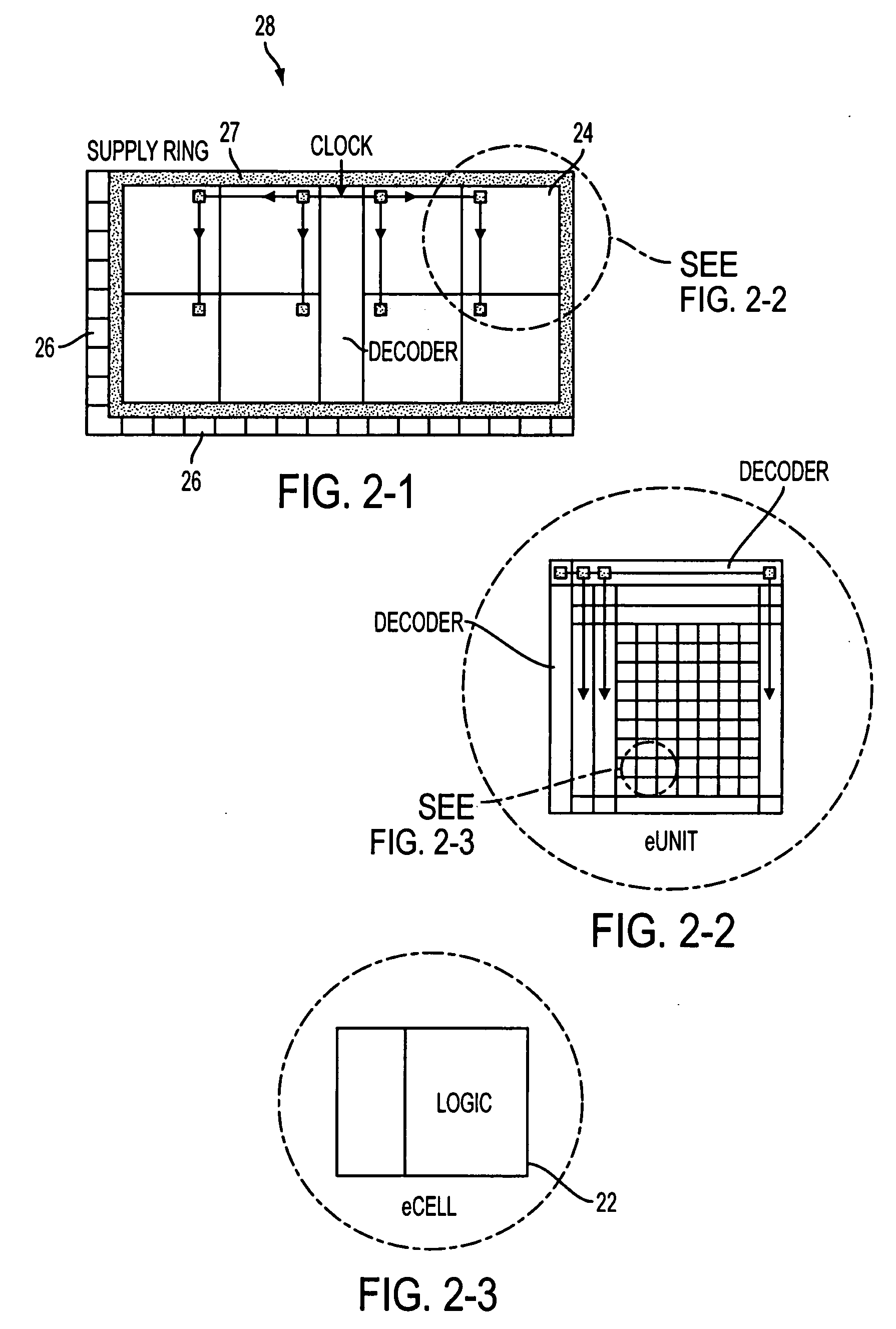

[0102] The current invention suggests the use of a much less common lithography technique called direct-write using e-Beam. Such could be done, for example, with direct-write e-Beam—Leica ZBA32 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com