Method and apparatus reducing electrical and thermal crosstalk of a laser array

a laser array and electrical and thermal crosstalk technology, applied in the field of lasers, can solve the problems of reducing the yield of manufacturers, affecting the operation performance of laser arrays, and limiting the capacity of optical communication systems, so as to achieve the effect of improving the yield of manufacturers and improving the operating performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Laser Array

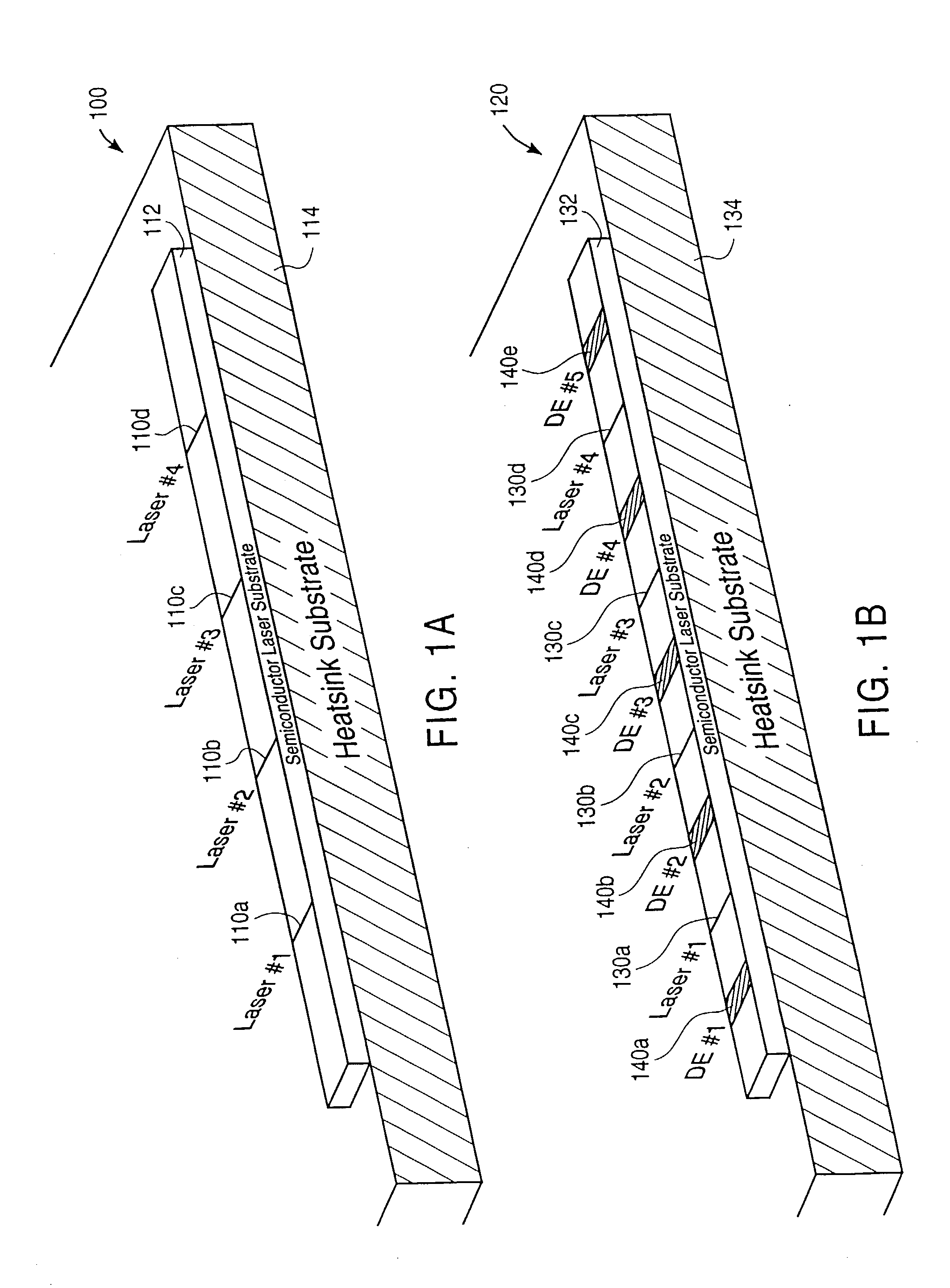

[0026]FIG. 1A is a diagram of a conventional laser array 100. As shown in FIG. 1A, laser array 100 includes four lasers 110a through 110d. The four-laser array (NL=4) is shown by way of example. Other laser arrays can include more or fewer lasers. Each laser 110 is a narrow multi-layer diode strip (e.g., typically a few microns in width) formed in the top few microns of a semiconductor laser substrate 112 that is, for example, approximately 100 microns in thickness. Laser substrate 112 sits on top of a heat sink substrate 114. Semiconductor laser substrate 112 is also referred to as a laser array bar. Lasers 110 are typically equally spaced apart (e.g., by approximately 0.25, 0.50, 0.75, or 1.0 mm).

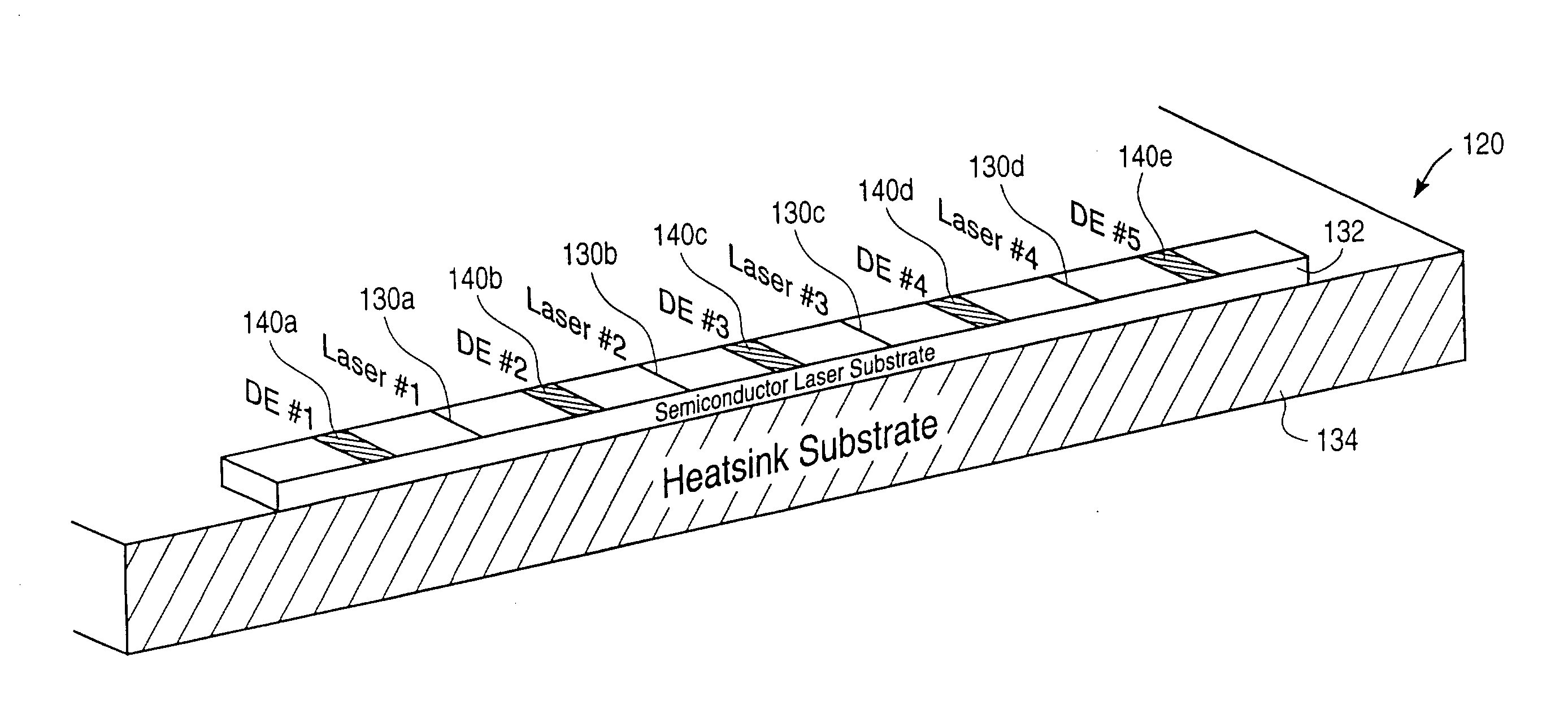

[0027]FIG. 1B is a diagram of a laser array 120 of the invention. As shown in FIG. 1B, laser array 120 also includes four lasers 130a through 130d that are dimensioned and evenly spaced similar to those in laser array 100. However, laser array 120 further includes five “dumm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com