Method and system for precisely positioning a waist of a material-processing laser beam to process microstructures within a laser-processing site

a laser beam and microstructure technology, applied in the direction of photomechanical equipment, manufacturing tools, instruments, etc., can solve the problems of insufficient link cutting, small device affecting the geometry of links, and possible substrate damage, so as to improve focus control, reduce the effect of spot size and small geometry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

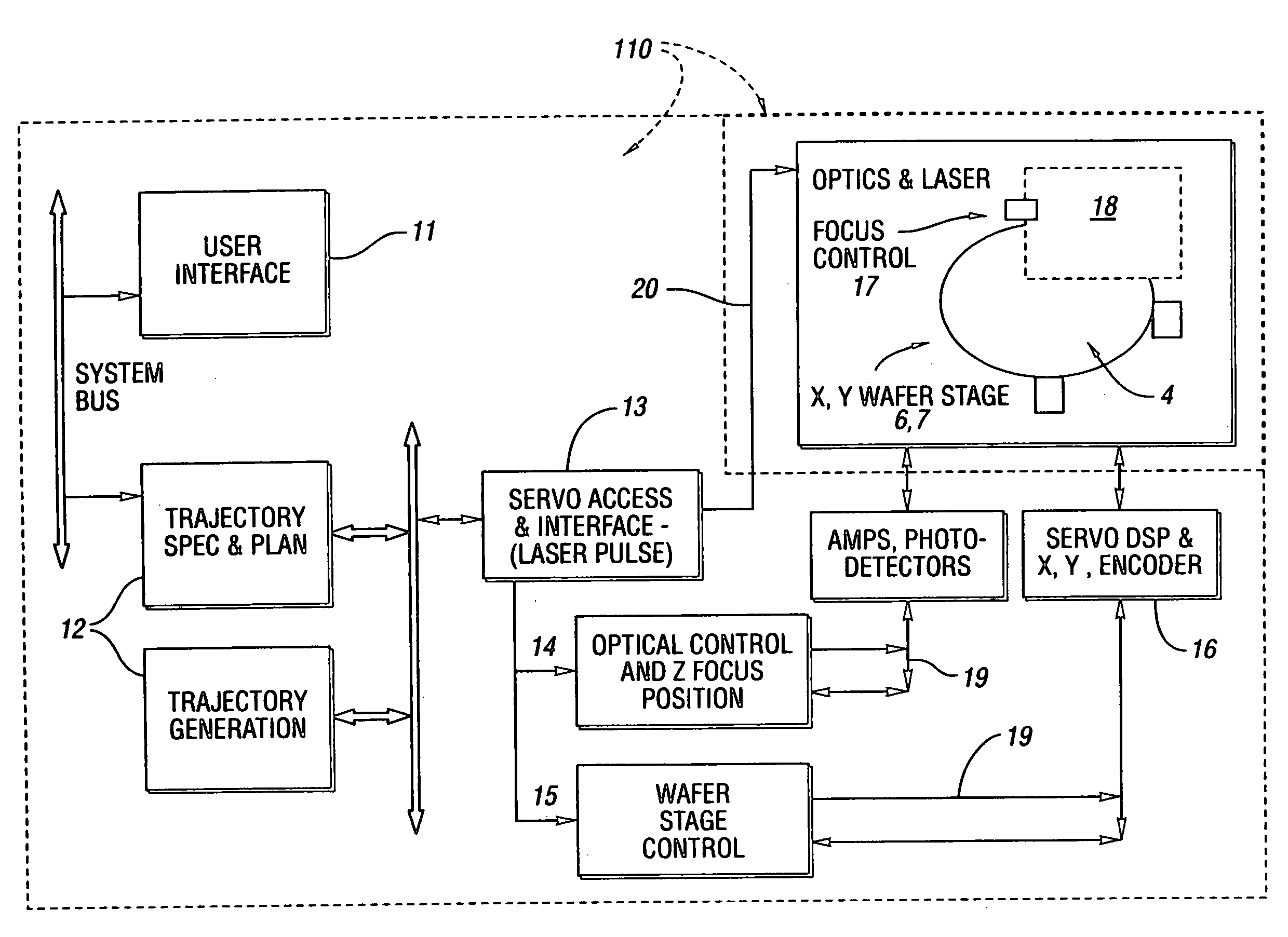

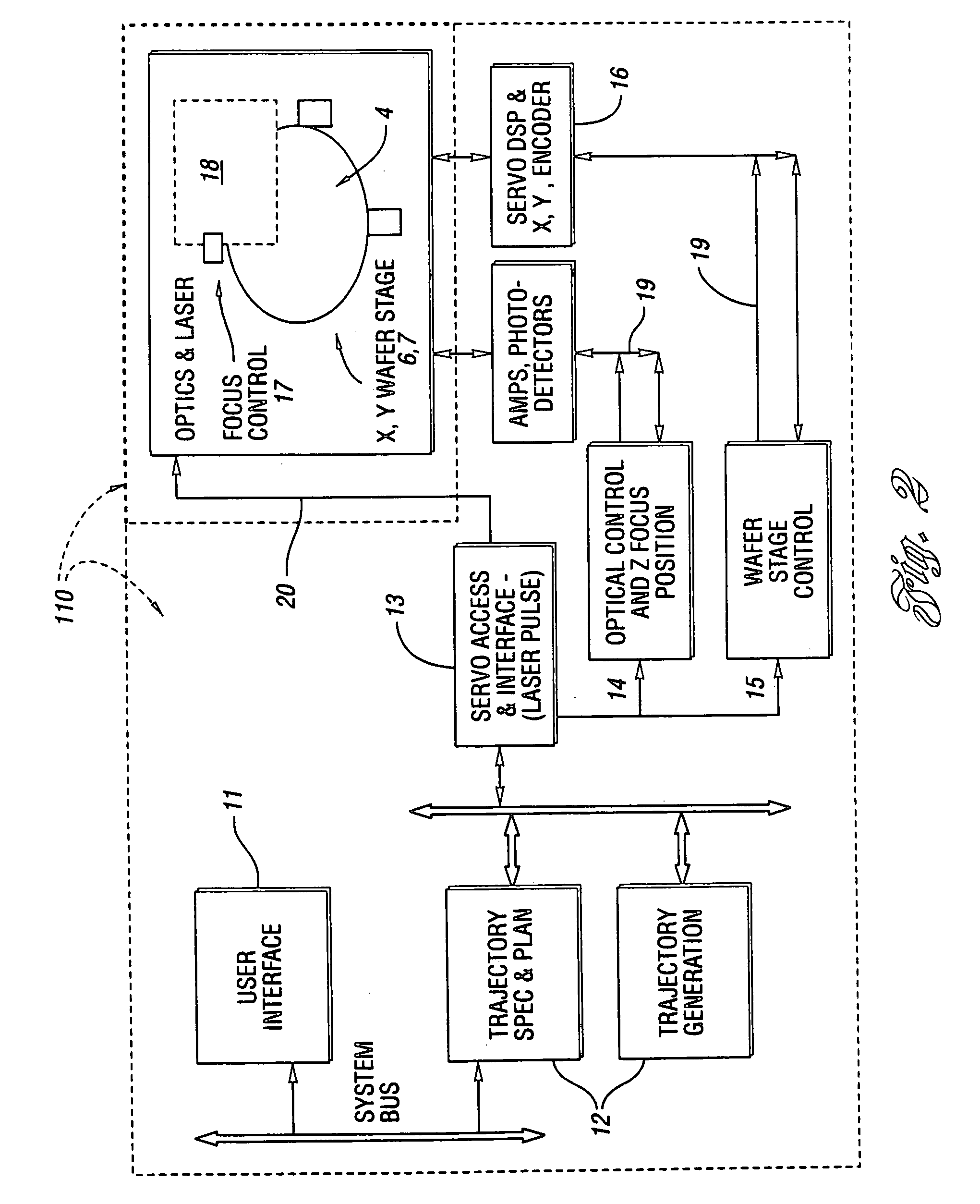

[0085] A preferred system of the present invention is shown in FIG. 2. A wafer 4 is positioned within the laser processing system 110 and database information from the user interface 11 is provided to identify the links (33 in FIG. 4) on the wafer which are to be ablated to repair defective memory cells.

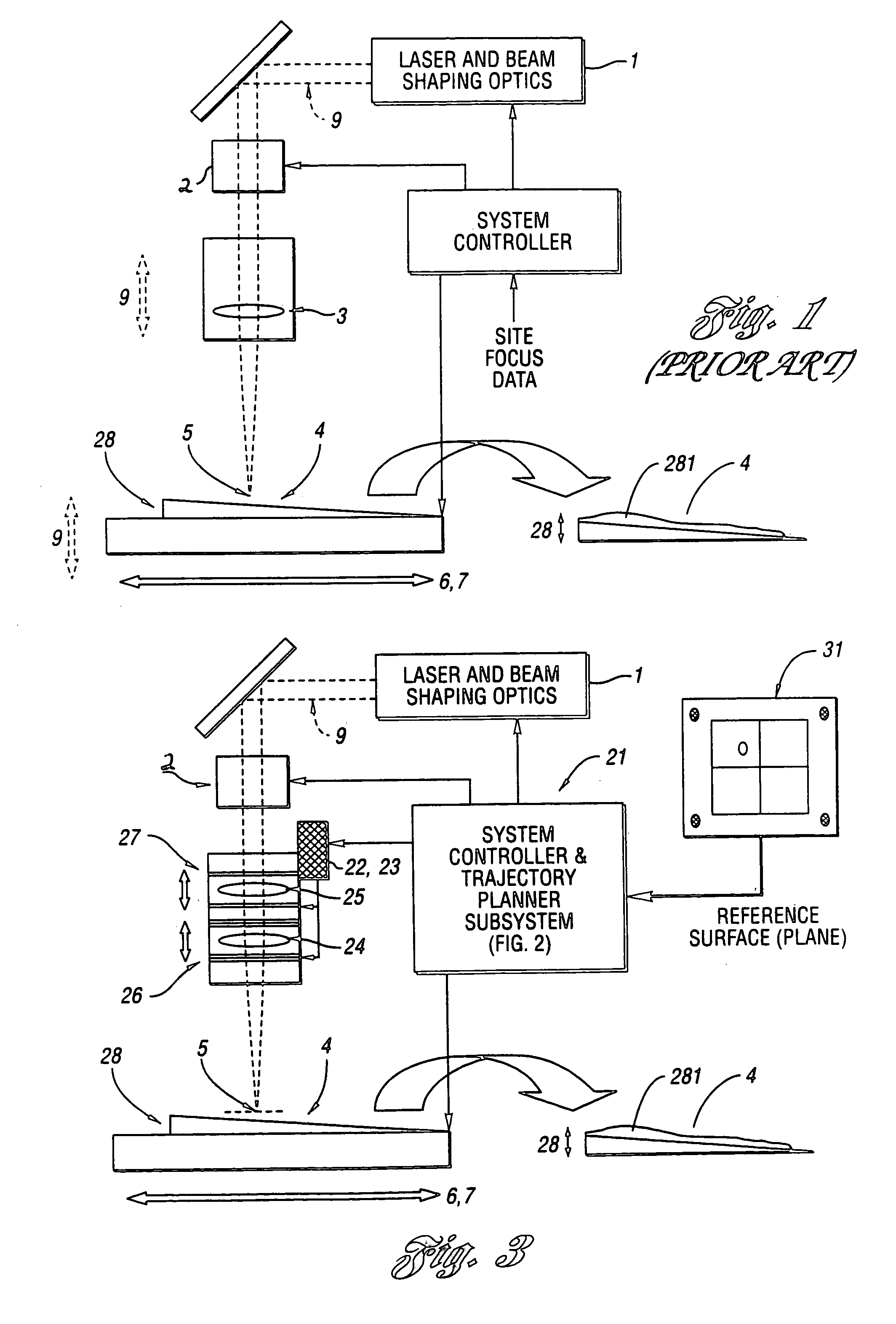

[0086] Referring to FIG. 3, wafers exhibit wedge 28 (i.e. a plane that is tilted with respect to the focal plane) and non-planar topology 281 which requires compensation. The wedge 28 and local curvature 281 are exaggerated in scale for the purpose of illustration. Based upon the specified locations of the defective cells regions are identified on the wafer (33 in FIG. 4) in reference height data is to be obtained. Such locations may be “bare wafer” regions that have little surface texture or other suitably defined regions that are generally selected to match the imaging and processing capabilities of the measurement sensor. Typically depth information will be obtained using a “dept...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Acceleration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com