Method and apparatus for selective pre-dispersion of extracted ion beams in ion implantation systems

a selective pre-dispersion and ion beam technology, applied in electrical equipment, nuclear engineering, electric discharge tubes, etc., can solve the problem of limiting the effect of space charge expansion that results from the entire extracted beam, and achieve the effect of mitigating the space charge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

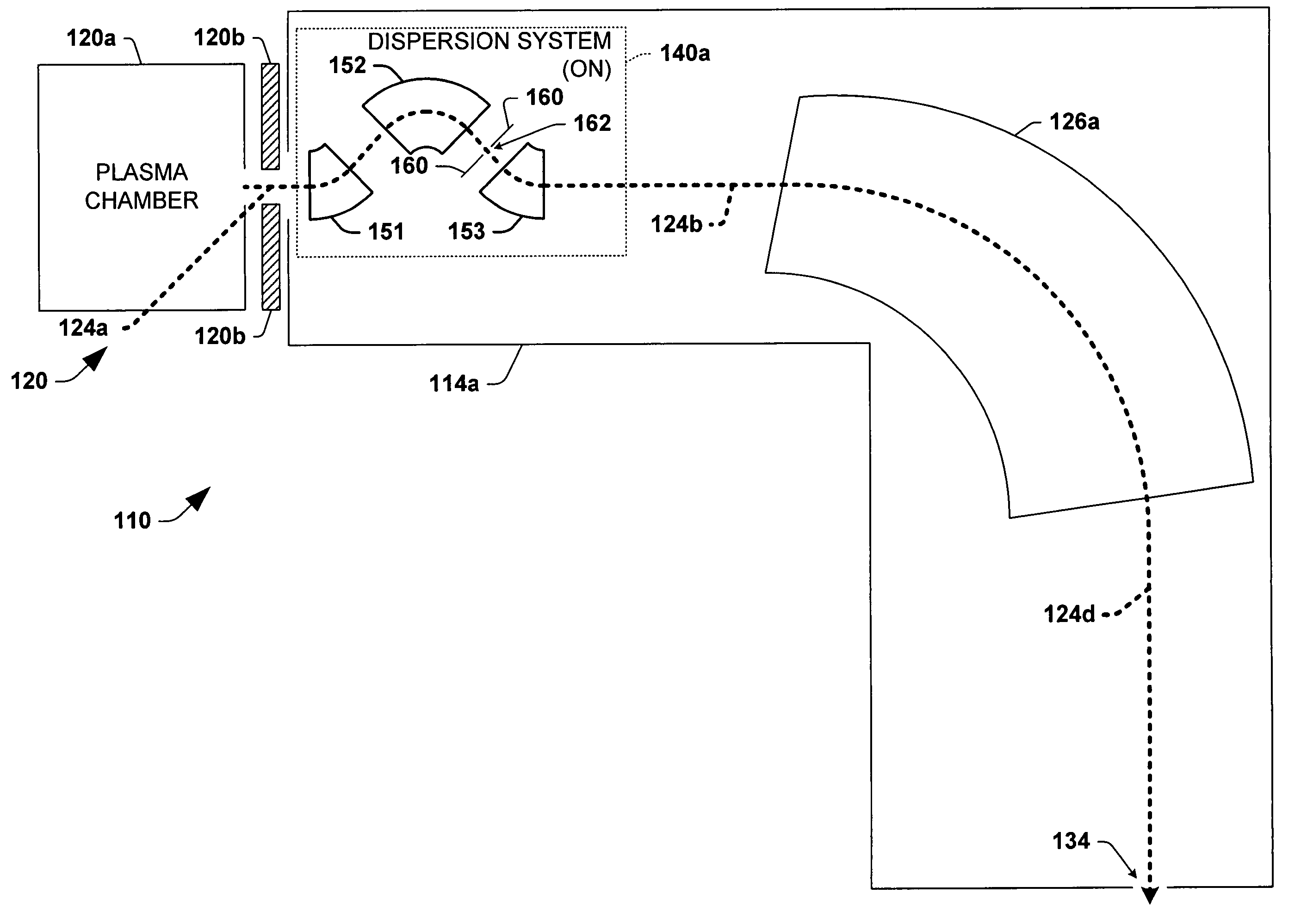

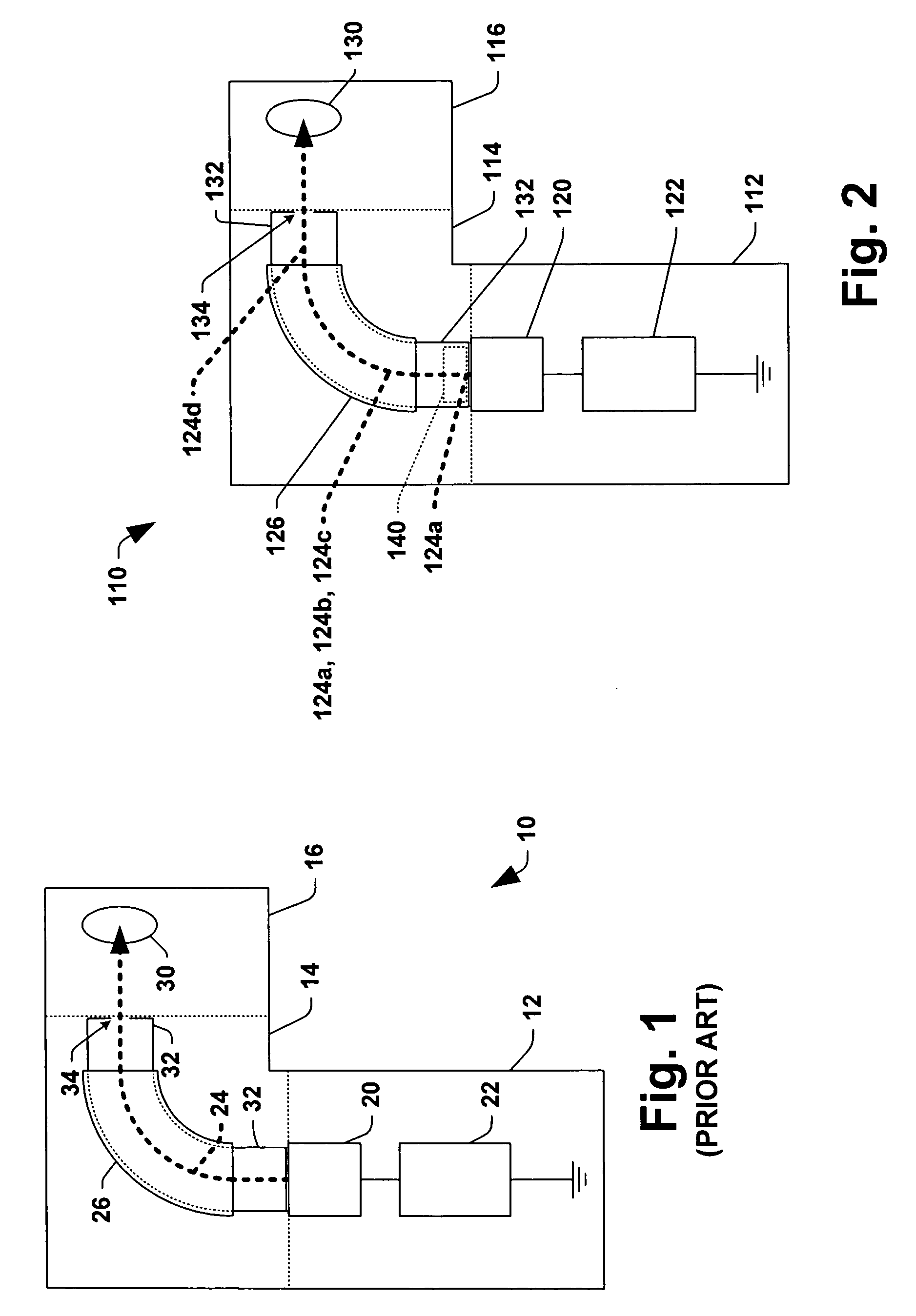

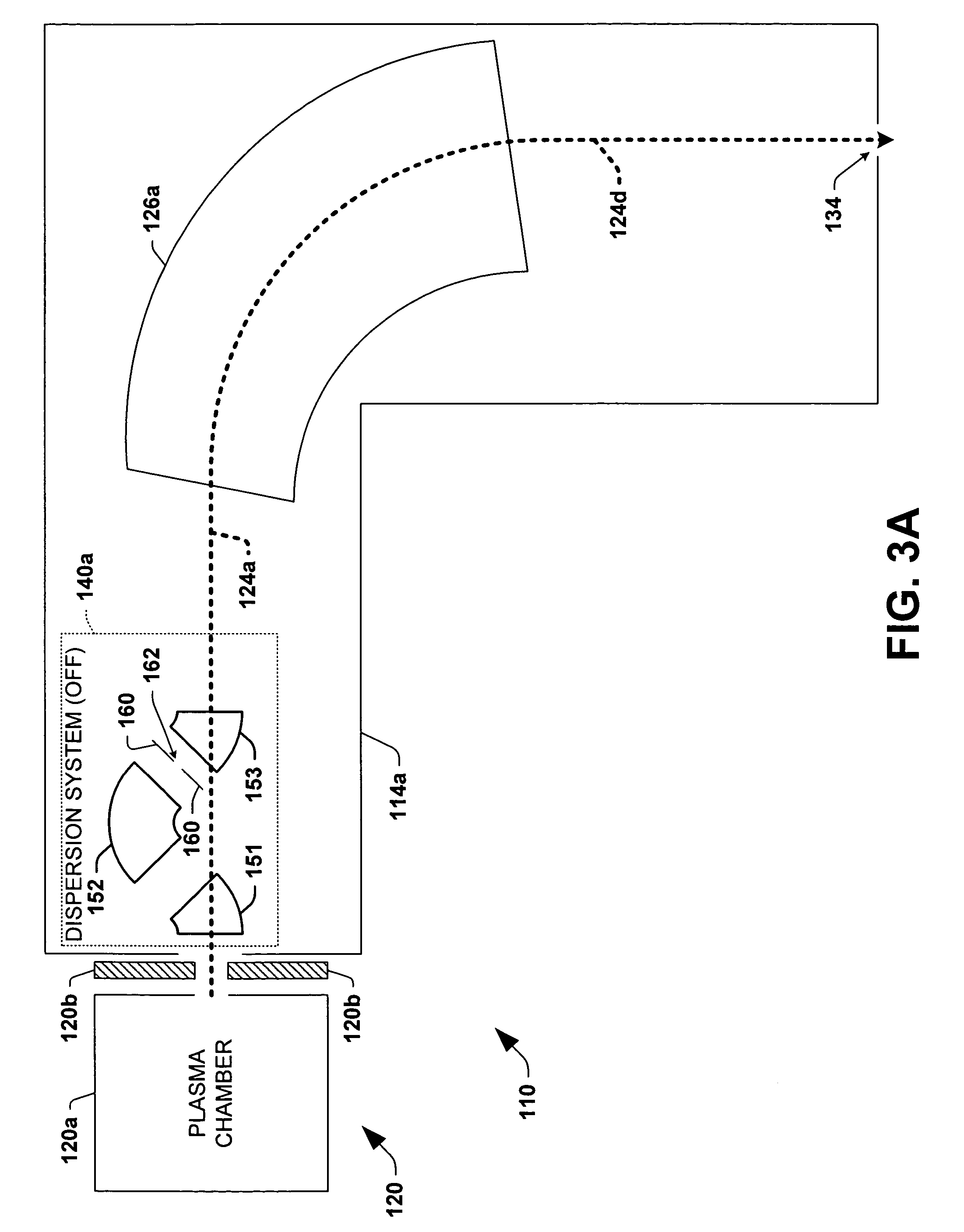

[0026] The present invention will now be described with reference to the drawings wherein like reference numerals are used to refer to like elements throughout, and wherein the illustrated structures are not necessarily drawn to scale. The present invention provides ion implantation systems and beamline assemblies therefor, having dispersion systems that selectively pre-disperse low energy beams prior to a main mass analyzer to facilitate beam transfer without beam blowup, and also to allow passage of higher energy beams directly to the main mass analyzer. Several examples of low energy implantation systems and beamline assemblies therefor are hereinafter presented in order to illustrate the various aspects of the invention. However, it will be appreciated that the invention may be advantageously employed in ion implanter systems apart from those illustrated and described herein, including high energy implanters having acceleration components.

[0027]FIG. 2 illustrates an exemplary i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com