Functional diaphragm coating material for protecting lithium metal negative electrode as well as preparation method and application thereof

A lithium metal negative electrode and coating material technology, which is applied in the direction of lithium batteries, battery pack components, electrical components, etc., can solve the problems of limited lithium ion diffusion rate, reduced battery Coulombic efficiency, and consumption of electrolyte, etc. Ion concentration, reducing space charge effects, slowing the effect of buildup formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

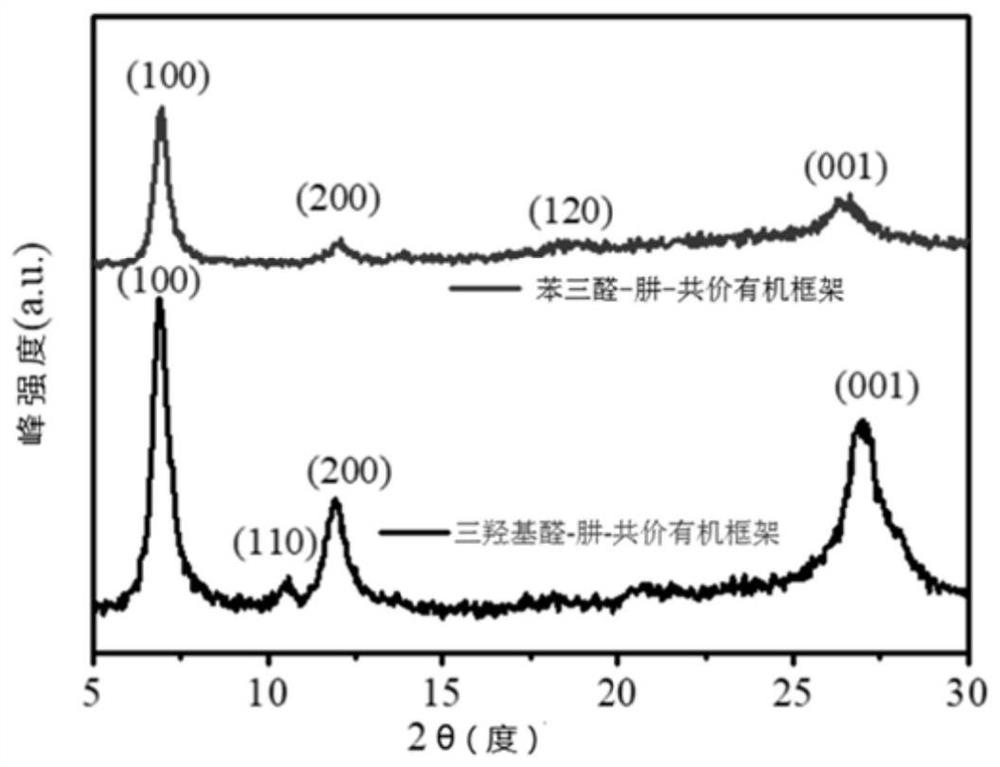

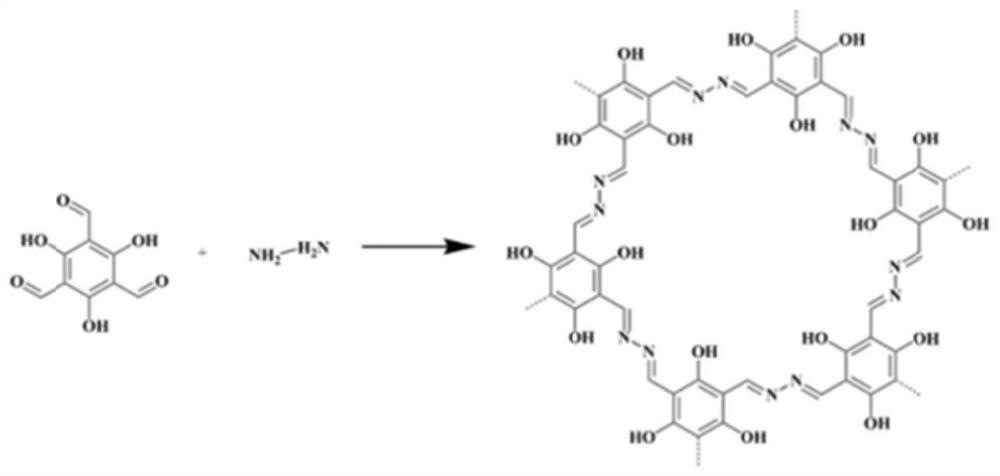

[0035] Preparation of a functional separator coating material-trihydroxyaldehyde-hydrazine-covalent organic framework:

[0036] Take 18 mg of 2,4,6-trihydroxy-1,3,5-benzenetricarbaldehyde and 64 μL of hydrazine hydrate (the molar ratio is 2:30), add 3 mL of methanol, 3 mL of tetrahydrofuran, and then add 6 mol / L acetic acid solution, the amount of acetic acid solution added is 10% of the total volume of the above mixture, and then argon gas is introduced and sealed, and the above mixed solution is placed in an oven at 120°C for 72 h, and the obtained reactants are respectively used in 1 , 4-dioxane, tetrahydrofuran and acetone for washing, that is, the red powder membrane coating material - trihydroxy aldehyde - hydrazine - covalent organic framework, such as figure 2 A schematic diagram of the reaction of a trihydroxyaldehyde-hydrazine-covalent organic framework is shown;

[0037] Such as figure 1 It is the SEM scanning image of trihydroxy aldehyde-hydrazine-covalent orga...

Embodiment 2

[0040] Preparation of a functional separator coating material-trihydroxyaldehyde-hydrazine-covalent organic framework:

[0041] Take 18 mg of 2,4,6-trihydroxy-1,3,5-benzenetricarbaldehyde and 85 μL of hydrazine hydrate (the molar ratio is 1:20), add 3 mL of methanol, 3 mL of tetrahydrofuran, and then add 6 mol / L acetic acid solution, the addition of acetic acid solution is 12% of the total volume of the above mixture, then pass through argon and seal it, place the above mixed solution in an oven at 120°C for 72 h, and use 1 , 4-dioxane, tetrahydrofuran and acetone for washing to obtain a red powder diaphragm coating material-trihydroxyaldehyde-hydrazine-covalent organic framework;

[0042] Mix 0.16 g of trihydroxyaldehyde-hydrazine-covalent organic framework, 0.06 g of 5% aqueous binder LA132, and 0.04 g of conductive agent carbon black (the mass ratio of the three is 4:2:1), and then drop 2.4 Prepare the slurry with n-propanol aqueous solution in mL, and coat it on one side o...

Embodiment 3

[0044] Preparation of a functional separator coating material-trihydroxyaldehyde-hydrazine-covalent organic framework:

[0045] Take 18 mg of 2,4,6-trihydroxy-1,3,5-benzenetricarbaldehyde and 71 μL of hydrazine hydrate (the molar ratio is 3:50), add 3 mL of methanol, 3 mL of tetrahydrofuran, and then add 6 mol / L acetic acid solution, the amount of acetic acid solution added is 15% of the total volume of the above mixture, then pass through argon and seal it, place the above mixed solution in an oven at 120°C for 72 h, and use 1 , 4-dioxane, tetrahydrofuran and acetone for washing to obtain a red powder diaphragm coating material-trihydroxyaldehyde-hydrazine-covalent organic framework;

[0046] Mix 0.20 g of trihydroxyaldehyde-hydrazine-covalent organic framework, 0.08 g of 5% aqueous binder LA132 and 0.04 g of conductive agent carbon black (the mass ratio of the three is 5:2:1), and then drop 2 Prepare the slurry with n-propanol aqueous solution in mL, and coat it on one sid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com