Separator and fuel cell using thereof

a fuel cell and separator technology, applied in the direction of cell components, cell component details, electrochemical generators, etc., can solve the problems of inability to obtain desired power generation performance, difficulty in obtaining fluid passages having desired depths and widths, and inability to uniformly react gas streams, etc., to achieve long use life, reduce costs, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

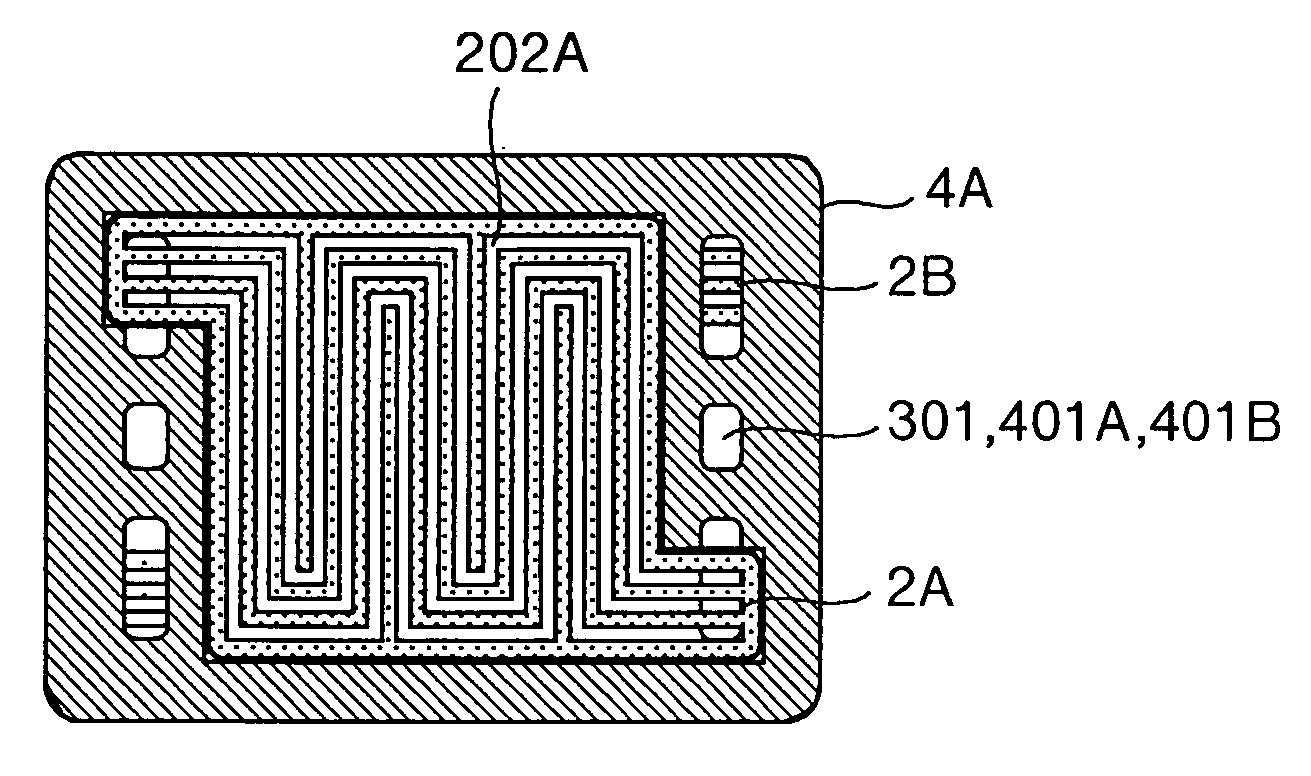

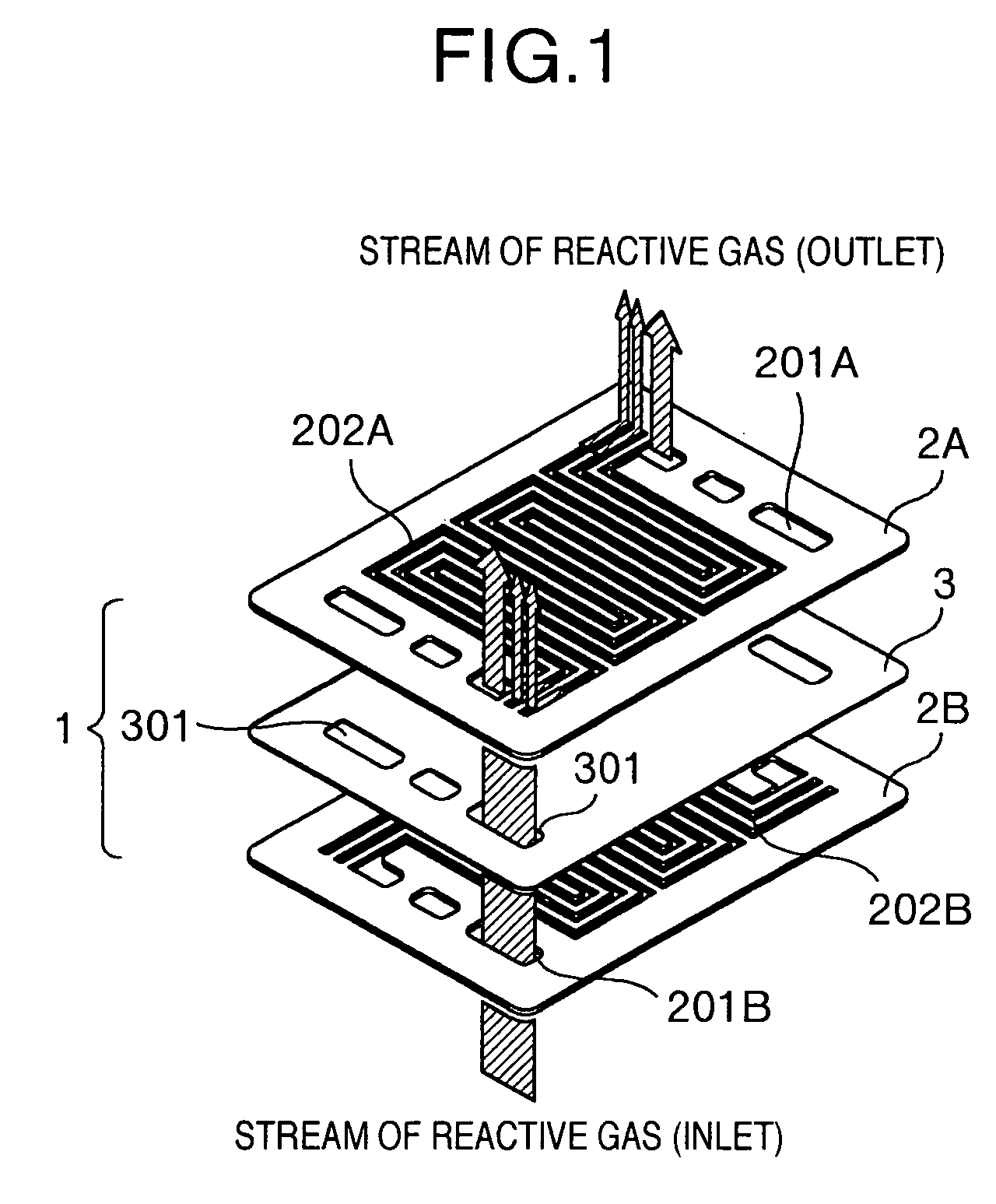

[0049] Explanation will be made of a power generation cell in an embodiment 1 of the present invention with reference to the drawings. Referring to FIG. 1 which shows a basic configuration of a separator according to the present invention, the single separator 1 is composed of covered metal panel 3 formed therein with manifolds 301, and passage boards 2A, 2B superposed over opposite surfaces of the covered metal panel 3 and formed therein with meandering through-channels for distributing reactive gas and cooling medium from the manifolds 301. The passage boards 2A, 2B are formed therein with meandering channels 202 which pierce therethrough and are also formed therein with a plurality of manifolds 201A, 201B as required.

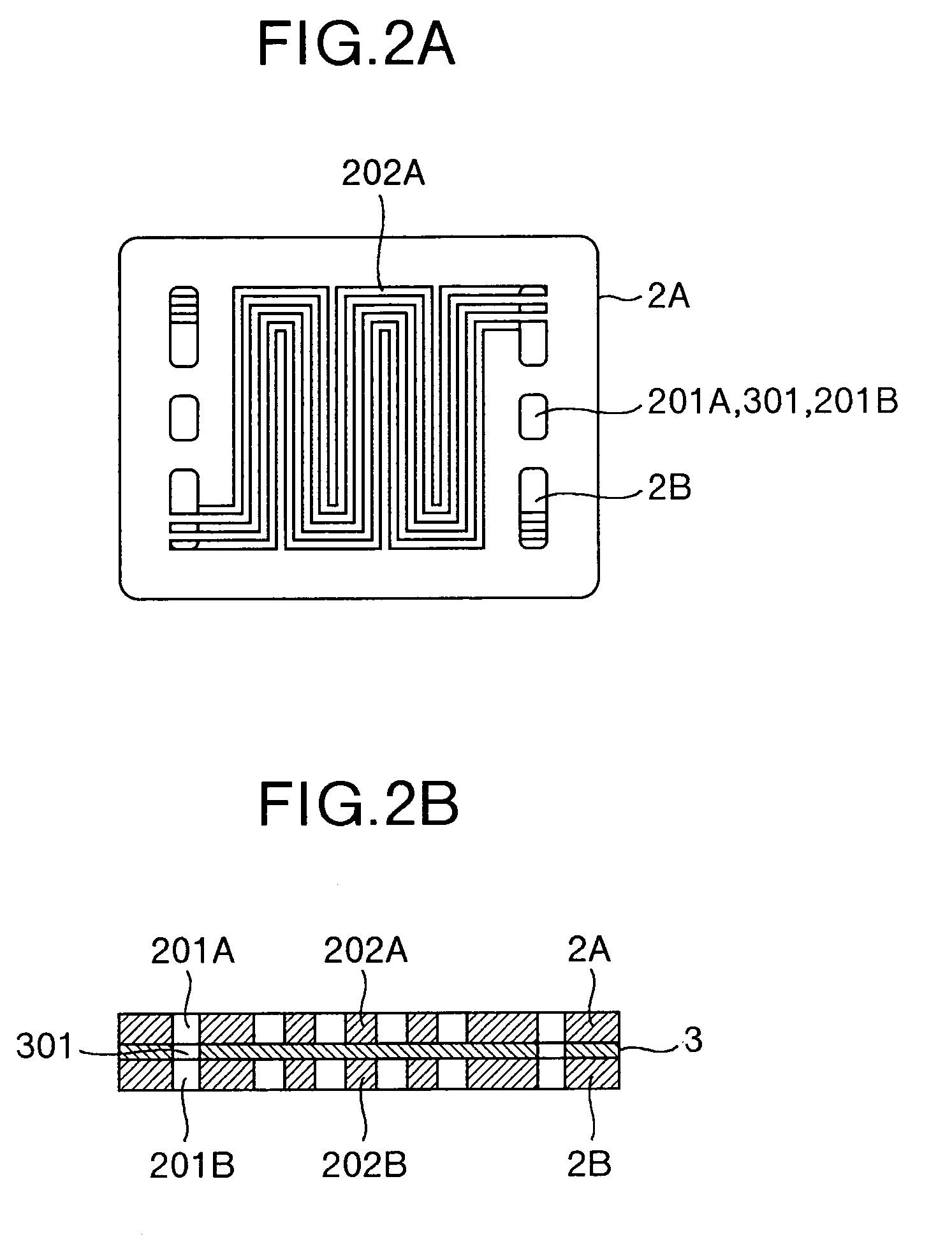

[0050] Referring to FIGS. 2A and 2B which show the covered metal panel 3 and the passage boards 2A, 2B which are superposed with each other, one upon another, interposing therebetween the covered metal panel 3, that is, FIG. 2A is a top plan view and FIG. 2B is a sc...

embodiment 2

[0061] Explanation will be hereinbelow made of an embodiment 2 of the present invention with reference to FIG. 5. In this embodiment, the passage boards 2 are made of conductive porous materials. If the passage boards 2 are made of porous material, the quantity of gas fed to the electrode by way of the passage board can be increased, and accordingly, there can be offered such an advantaged that the power generation voltage and the diffusion limit current can be enhanced. Referring to FIG. 5 which shows the separator 1 using the porous passage boards 2, since the passage boards 2 are made of porous materials, the reactive gas can flow though the porous materials, smoothly. Thus, the single passage board 2 as stated in the embodiment 1 cannot be used.

[0062] In this embodiment, by arranging the gaskets 4 around the passage boards 2, it is possible to restrain occurrence of cross-leakage of reaction gas from the anode to the cathode or from the cathode to the anode, leakage between the...

embodiment 3

[0065] Explanation will be hereinbelow made of an embodiment 3 with reference the accompanying drawings. In this embodiment, the covered metal panel 3 as used in the embodiment 1 or 2 is formed therein with slits 310 in a part corresponding to an electrode (the passage channels part of the passage board 2). Referring to FIG. 7 which shows a separator 1 having the covered metal panel 3 formed therein with the slits 310, the basic configuration of the separator in this embodiment is the same as that in the embodiment 1 shown in FIG. 1, except the covered metal panel 3. The part of the covered metal panel 3 in which the slits 310 are formed is a zone where the passage channels 202 corresponding to the electrode in the passage boards 2A, 2B which are mated with each another are superposed with each other. This configuration is shown in FIG. 8.

[0066] The two passage boards 2A, 2B which are superposed with each other are shown in the upper right part of the figure while the covered metal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com