Stirred-tank reactor system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

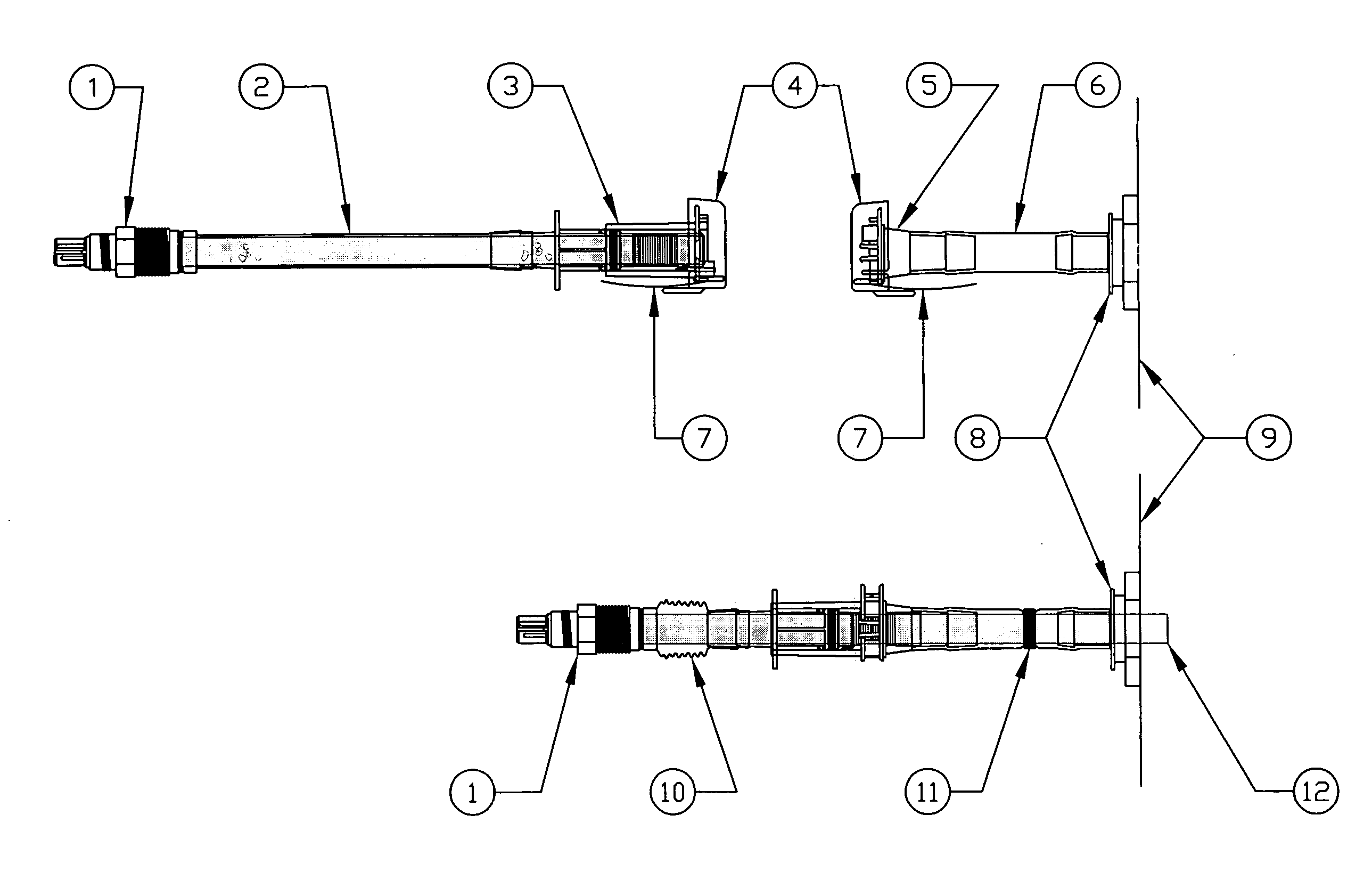

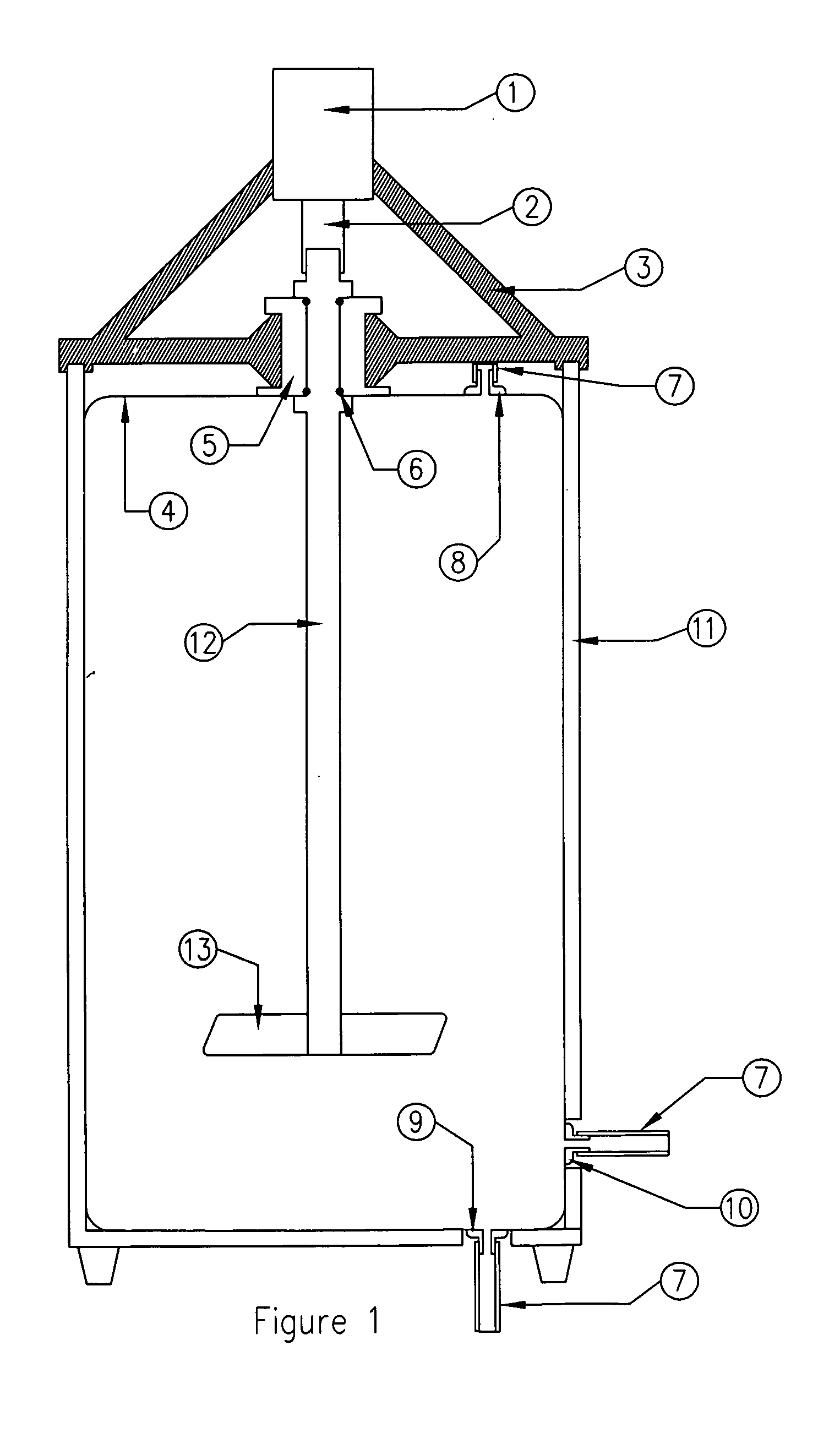

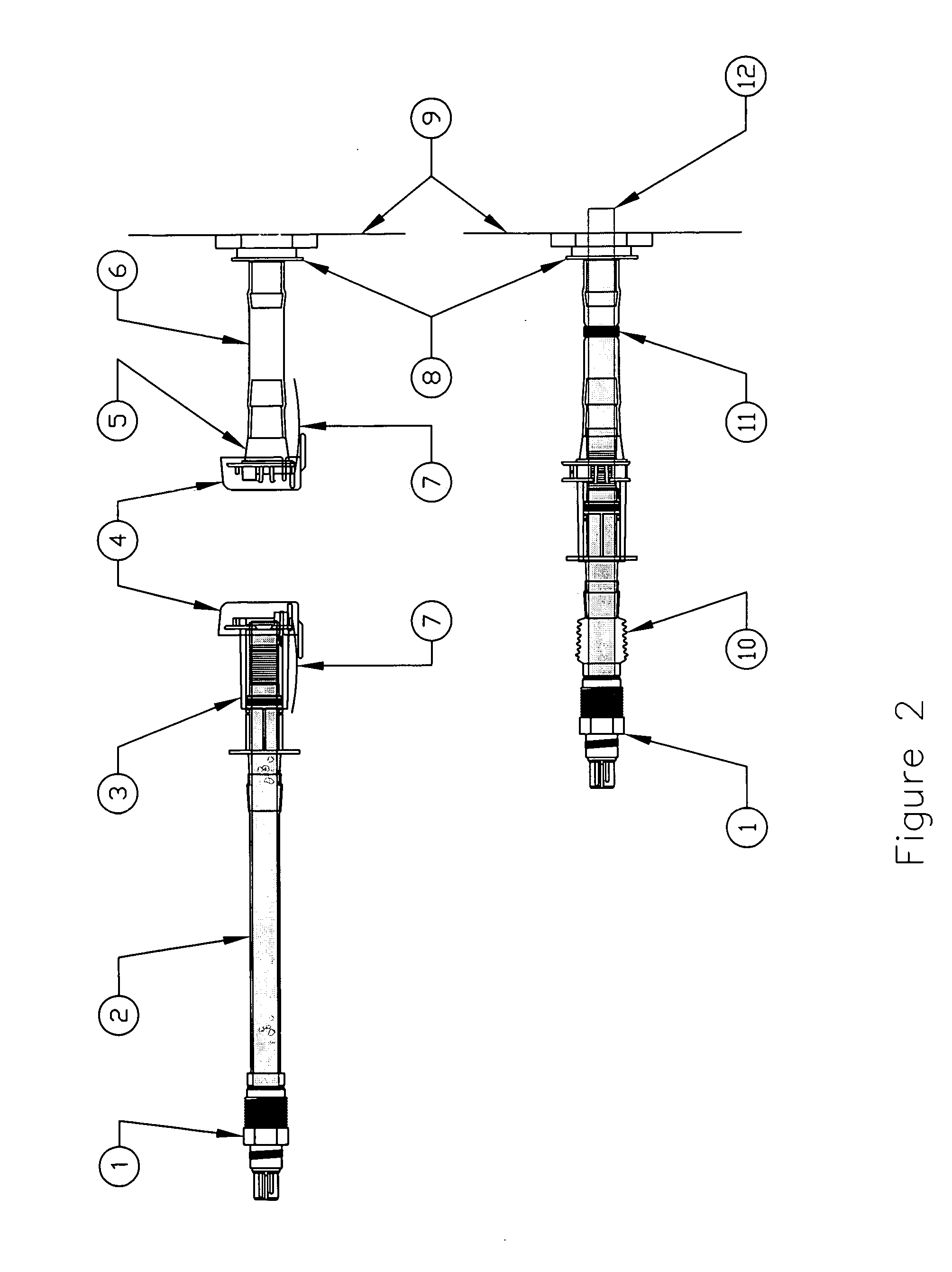

Image

Examples

Embodiment Construction

a) Definitions and General Parameters

[0018] The following definitions are set forth to illustrate and define the meaning and scope of the various terms used to describe the invention herein.

[0019] The term “flexible bag” refers to a container that holds a fluidic medium. The bag may include one or more layer(s) of flexible or semi-flexible waterproof material depending on size, strength and volume requirements. The inside surface of the bag is preferably smooth and provides a sterile environment (e.g., for culturing cells or other organism, for food production, etc.). The bag may include one or more openings, pouches (e.g., for inserting one or more probes, devices, etc.), ports (e.g., for the connection of one or more probes, devices, etc.) or the like. Furthermore, the bag provides a disposable alternative to a solid vessel in a conventional stirred-tank bioreactor. The flexible bag may further include a shaft, an impeller, a bearing and seals or o-rings, and may be entirely di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com