Contiguous capillary electrospray sources and analytical devices

a capillary electrospray and source technology, applied in the direction of centrifugal wheel fertilisers, separation processes, particle separator tube details, etc., can solve the problems of large dilution of eluting analytes, sensitivity suffers, and the limits of common detection techniques are particularly eviden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

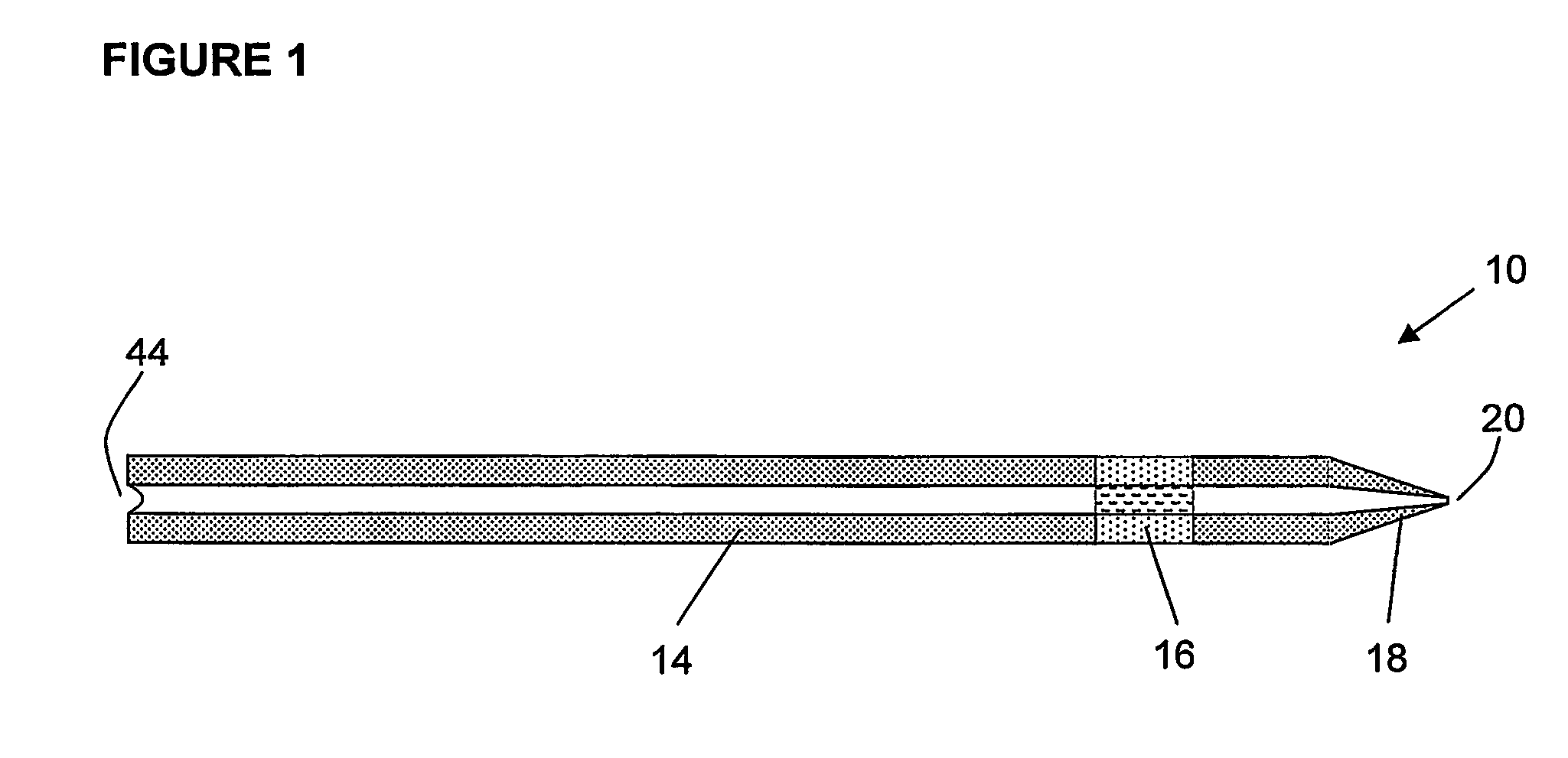

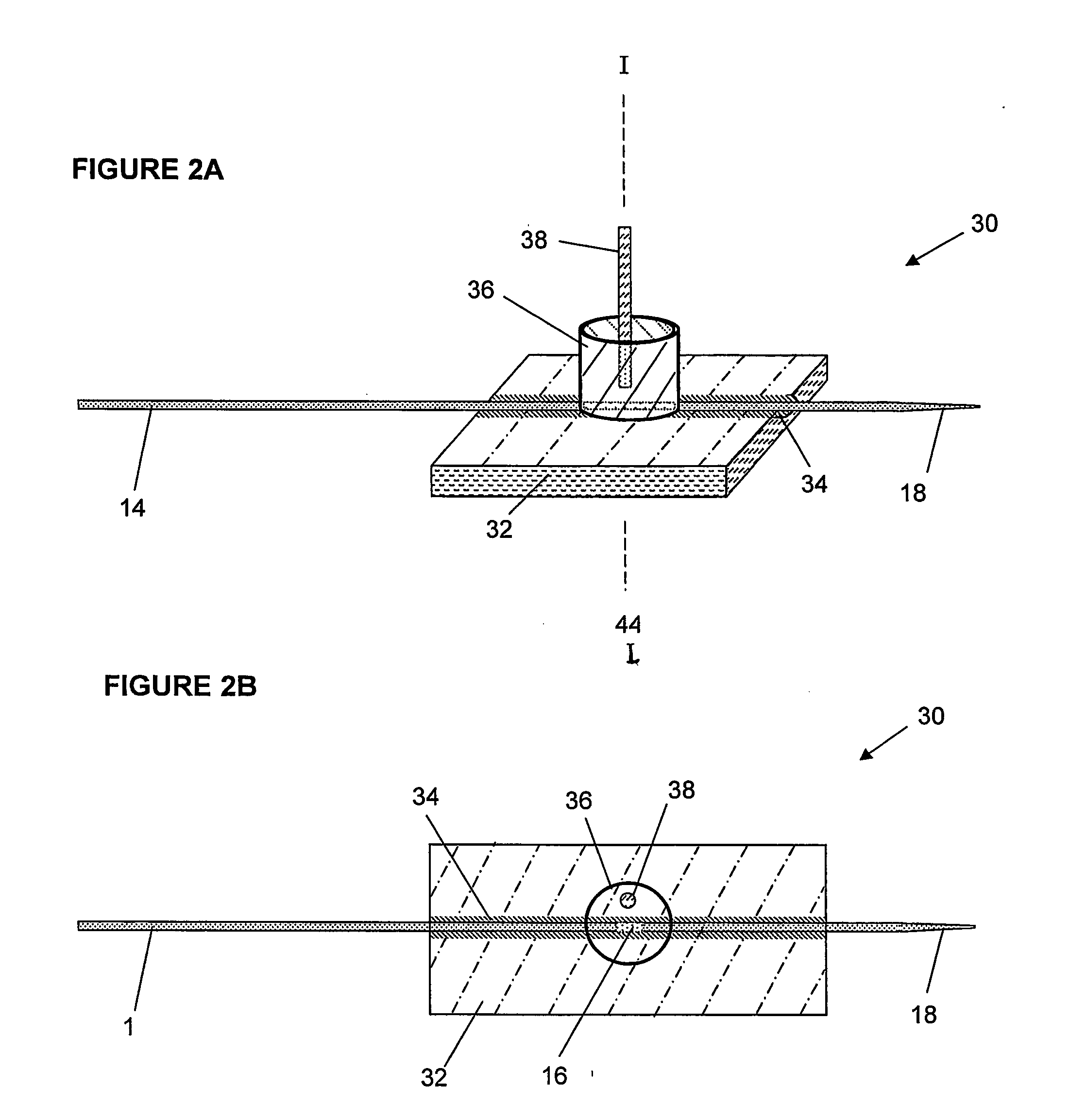

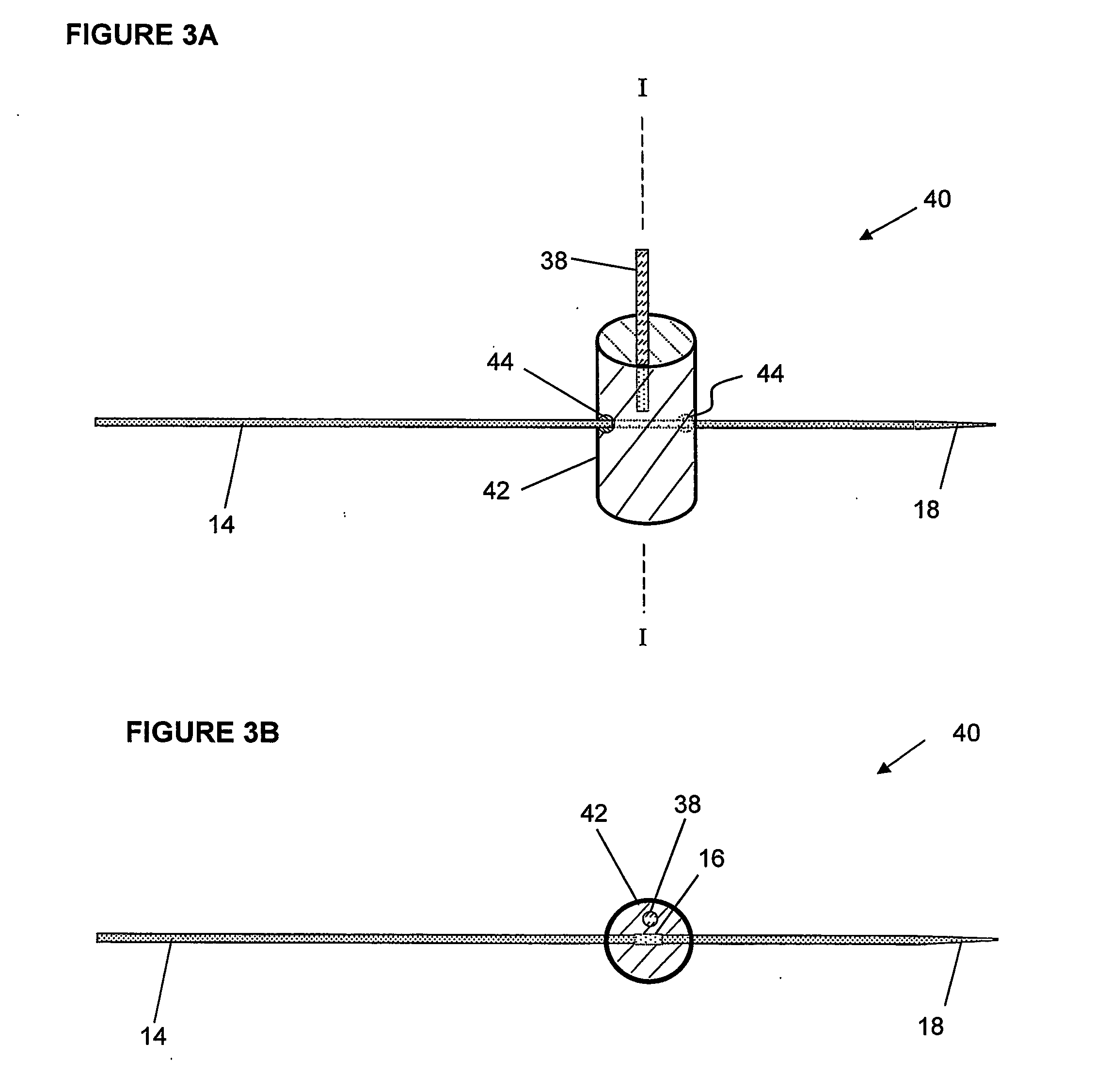

[0081] Contiguous capillaries. The following procedure describes the fabrication the contiguous capillary electrospray sources prepared from commercially available polyimide-coated fused silica capillaries (Polymicro Technologies, Phoenix, Ariz.). A spray tip was prepared by heating the capillary (75 cm long, 360 μm o.d., 50 μm i.d.) near the spray tip end with a microtorch and pulling it to draw down the inside diameter of the capillary to approximately 25 um. The polyimide coating was partially removed from a 3˜4 mm section of the capillary at a distance of 5 cm from the spray tip, to provide a partially (⅓) circum-etched capillary. The capillary was trimmed to a total length of 60 cm, and was mounted on an electrospray assembly as shown in FIGS. 2A and 2B. The assembly was constructed from a 4.5 cm×1.5 cm acrylic plastic substrate with a channel milled along its length having a depth that was slightly larger than the capillary diameter, and a 1.5 cm×1 cm i.d. acrylic plastic rese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com