Isoflavone-beta-D-glucan produced by Agaricus blazei in the submerged liquid culture and method of producing same

a technology of isoflavone-beta-d-glucan and liquid culture, which is applied in the field of isoflavone-beta-d-glucan produced by submerged liquid culture of agaricus blazei, can solve the problems of lowering immunity and liver function, commercialization of mushroom mycelium culture extracts, and adverse effects, and achieves no toxic effect on normal cells, and remarkable anti-cancer effect of low and medium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

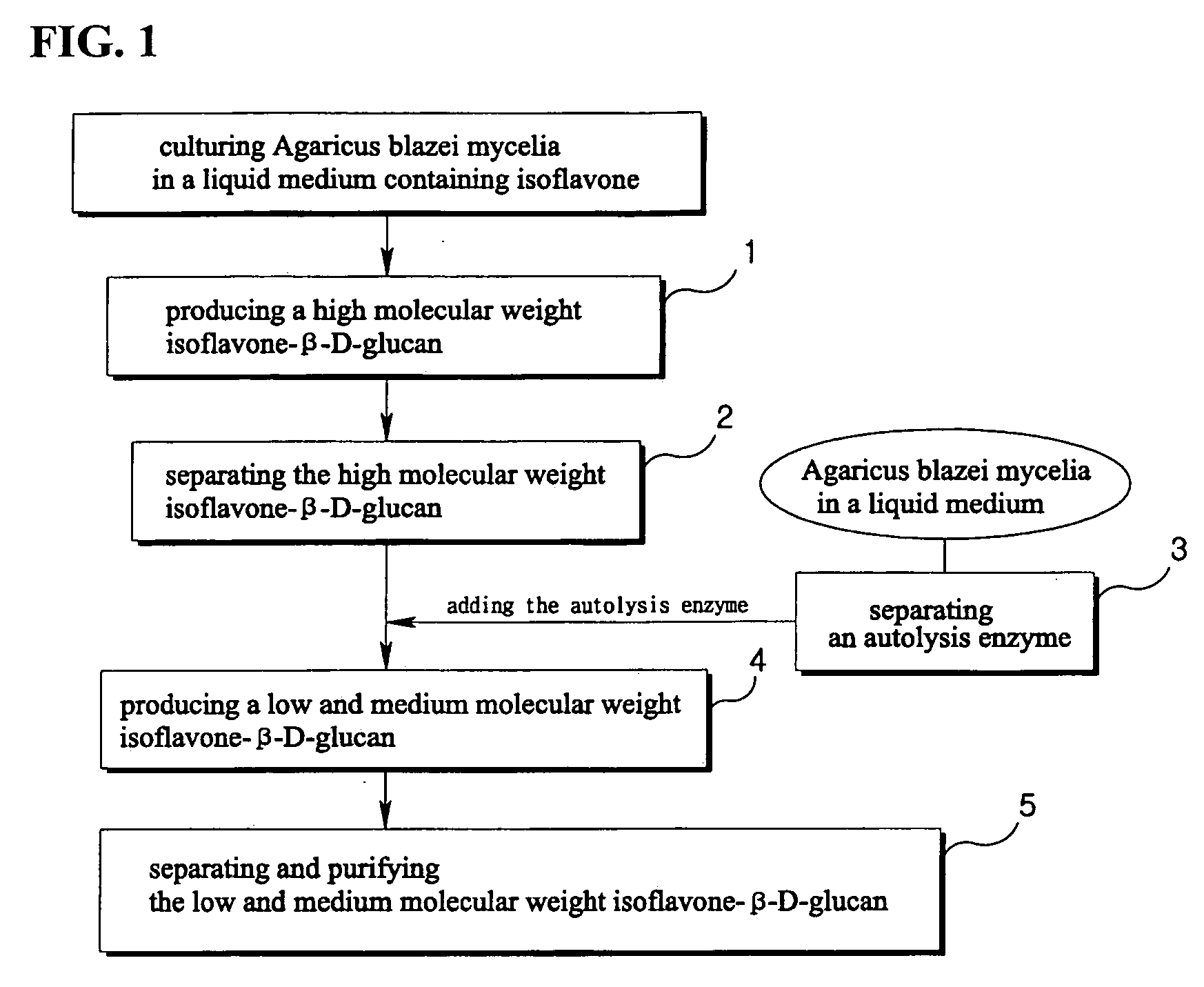

Production and Separation of High Molecular Weight Isoflavone-β-D-glucan

[0072] The culture medium contained soybean powder or natural source including soybean powder. Natural isoflavone separated from soybean or synthetic isoflavone may also be used. The liquid medium were added with brown sugar as carbon source and inorganic salts, and then autoclaved at 120° C. for 30 minutes.

[0073] AB mycelia were inoculated in the liquid culture medium containing isoflavone and cultured with aeration or stirring for 1 to 7 days to produce high molecular weight isoflavone-β-D-glucan. The molecular weight of the high molecular weight isoflavone-β-D-glucan was at least 30,000.

[0074] Liquid culture of AB mycelia was extracted with boiling water at 100° C. for 10 hours, and the extract was autoclaved at 121° C. for 1 hour.

[0075] The extract of liquid culture of AB mycelia was treated with 80% ethanol to make precipitation and then centrifuged to remove supernatant. The precipitate was separated t...

example 2

Selection of Ethanol Fraction Having the Highest Content of High Molecular Weight Isoflavone-β-D-glucan

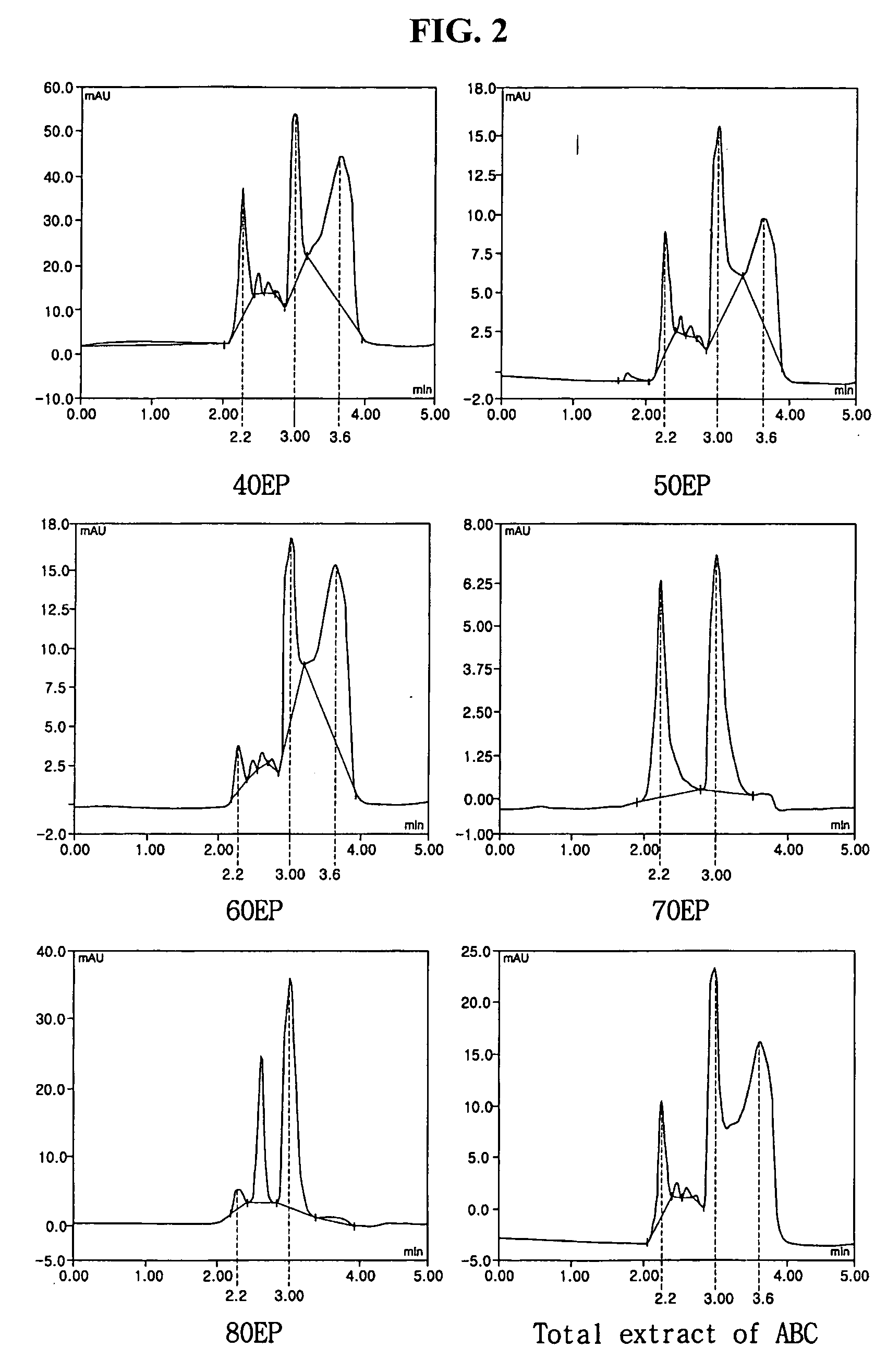

[0076] The extract of liquid culture of AB mycelia was suspended in ethanol to prepare 10 to 80% ethanol solution to induce precipitation. Each precipitate was separated and then applied to Biosep S-2000 column.

[0077]FIG. 2 is HPLC chromatograms of the extract of liquid culture of Agaricus blazei mycelia treated with various concentrations of ethanol solution (40, 50, 60, 70 and 80% ethanol) and then separated with Biosep S-2000 column. The chromatogram on the right side below represents the chromatogram of total extract of liquid culture of AB mycelia. In FIG. 2, horizontal axis represents time (minutes) and vertical axis represents length (mAU).

[0078] As shown in FIG. 2, the high molecular weight isoflavone-β-D-glucan, obtained by treating 80% ethanol to the liquid culture of AB mycelia to induce precipitation, hereinafter referred to ‘80 EP (80% ethanol precipitate)’, shows s...

example 3

Separation and Fractionation of Autolysis Enzyme

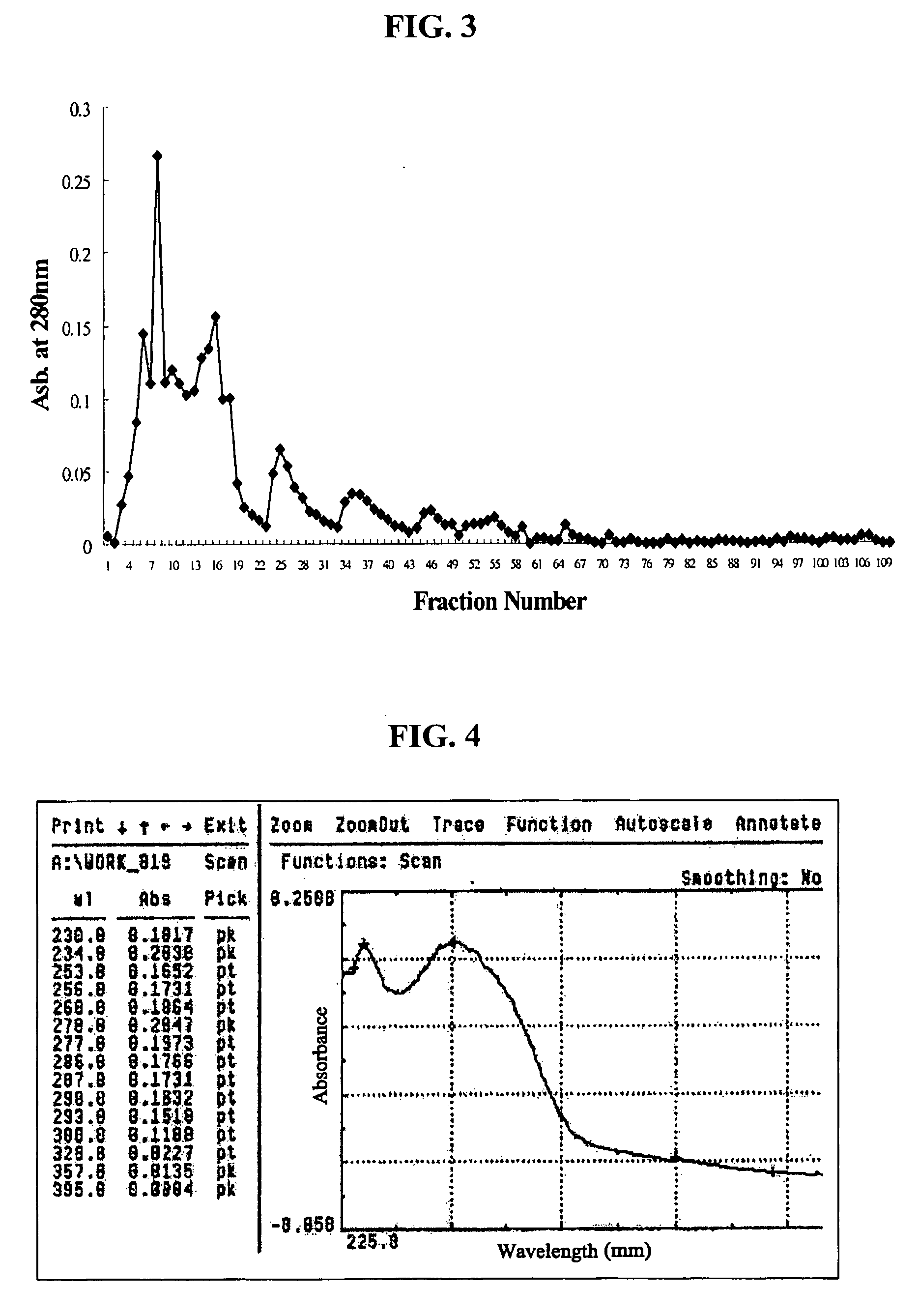

[0080] The separation of autolysis enzyme was carried out by filtrating the liquid culture of AB mycelia at reduced pressure. TCA (trichloroacetic acid) was added to the filtrate to the concentration of 10% and the mixture was placed at 4° C. for 24 hours. The resultant was centrifuged at 4° C. and 10,000 rpm for 15 minutes to obtain the precipitate.

[0081] The precipitate was further fractionated by DEAE (diethylaminoethyl) column chromatography and each fraction was determined its UV absorbance at 280 nm.

[0082]FIG. 3 shows fractionation of the precipitate of the liquid culture of Agaricus blazei mycelia by DEAE column chromatography. In FIG. 3, horizontal axis represents number of each fraction and vertical axis represents UV absorbance at 280 nm. As shown in FIG. 3, UV absorbance of each fraction was monitored and eight fractions were obtained showing UV absorbance at 280 nm. Fraction #2 (tube #8) showed the maximum UV absorbance....

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| pH | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com