[0013] It is accordingly a primary objective of the present invention to provide an

improved method of facilitating the

urination by men from a standing position into a toilet, which

improved method uses only a disposable paper guide which relies on gravity and the

surface tension or intermolecular forces of the

urine stream itself to constrain the urine path onto the guide and downward into the toilet. Thus, this device is relatively inexpensive, may be easily and conveniently carried on the person or dispensed in a rest room and is of novel and simple construction.

[0014] It is a primary objective of the present invention to provide an

improved method of facilitating the

urination by humans, particularly males urinating from a standing position, into a toilet, which improved method uses a

toilet paper which can be used conventionally, but has been specially treated or processed to allow the additional use as a urinary aid. This

dual purpose toilet paper relies (1) on the

surface tension or intermolecular forces of the

urine stream itself to constrain the urine path onto the paper guide and subsequently downward into the toilet by gravity, and (2) relies on sufficient strength being provided to the wet

toilet paper guide to support the vertical urine column during

urination by either (a) keeping a narrow region of the paper essentially dry via certain treatments, thus reducing the

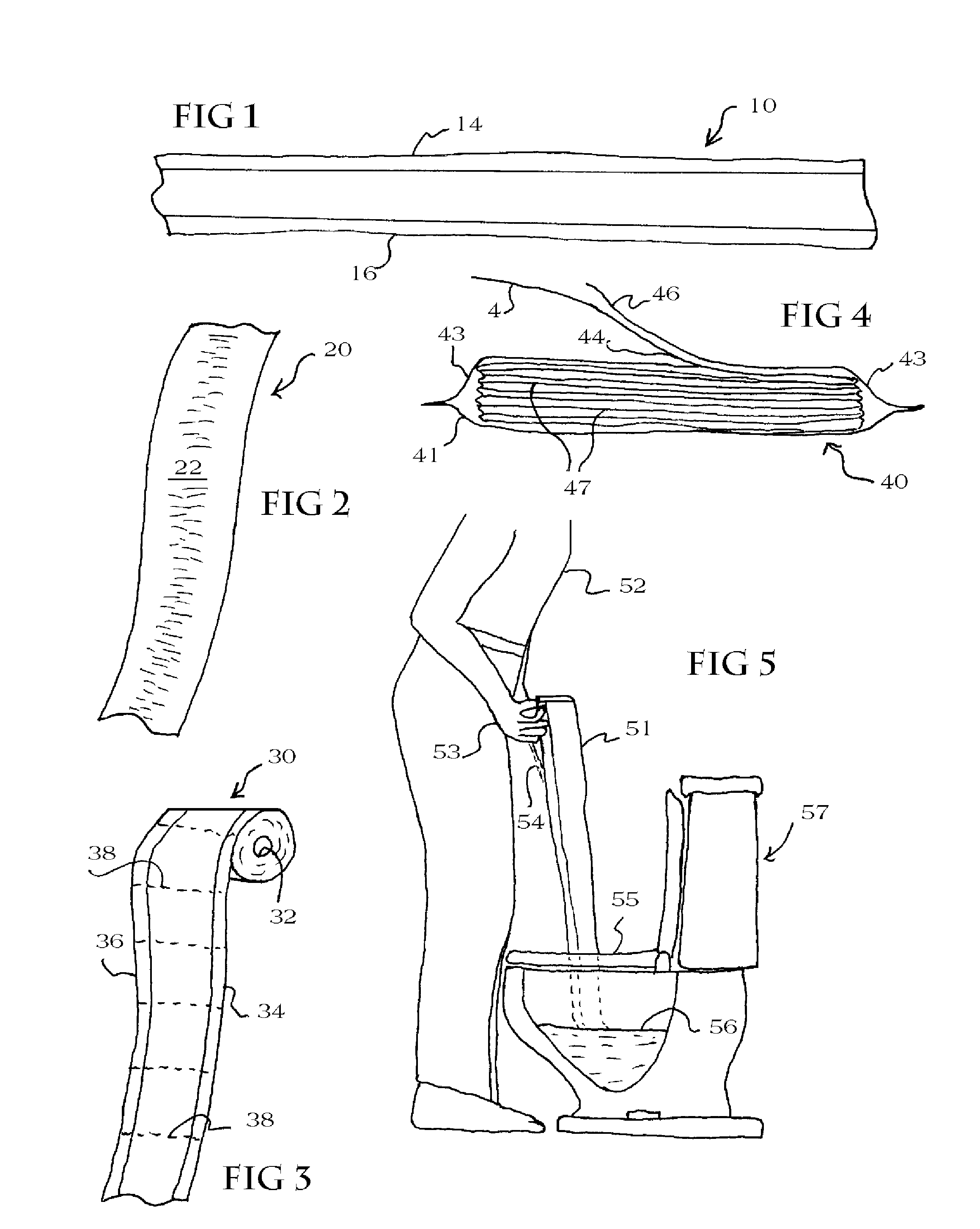

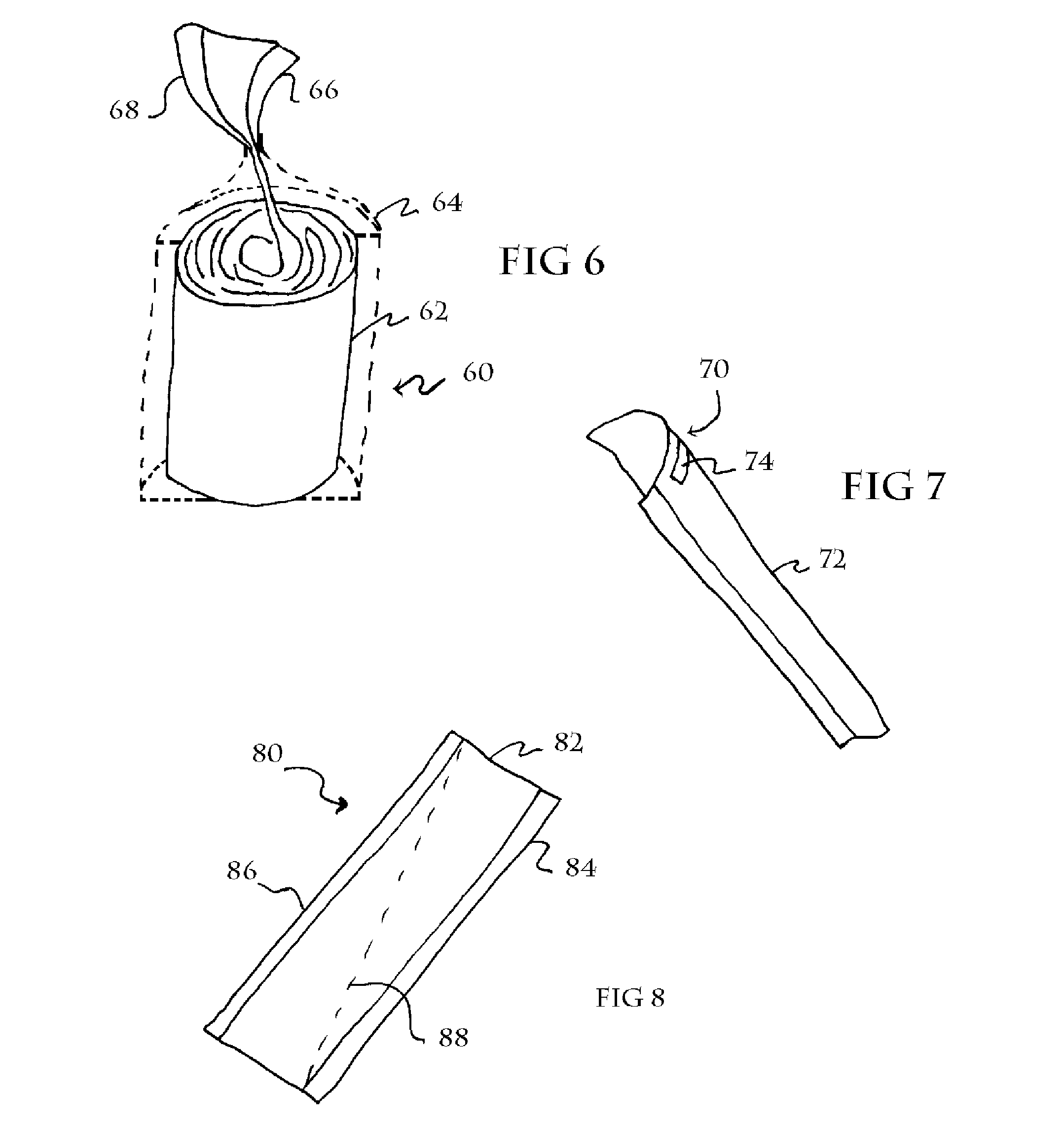

net weight of the urine column requiring support while retaining the dry tensile strength of the paper, and / or (b) strengthening the paper by the addition of a reinforcing region so it can support the full weight of the urine column. This product can be manufactured by very slight modifications to the present manufacturing processes for most conventional toilet papers and can be provided easily in every toilet using conventional toilet paper.

[0015] Most conventional toilet papers are manufactured to be absorbent, soft and easily dispersed upon flushing. However, very little, if any, loss of

efficacy is evidenced if one or more narrow regions are treated on the extremities of the web to make such region

water resistant for a short period of time. This may be achieved by well known methods, for example, by using conventional

coating technology such as gravure or

offset printing to coat the paper with

water resistant materials such as fluorocarbons, silicones or other hydrophobic materials, by

coating the paper with slowly dissolving materials such as

starch, by

coating the paper with water blocking materials such as clay, or by reducing the rate of absorption and penetration of water by physical treatments, for example by

embossing or tightly compressing the fibers under pressure. Alternatively, a wound roll of toilet paper can be coated by dipping the edges of the roll in a quantity of treating liquid and after removal, permitting it to dry. These water resistant regions benefit the invention by reducing the total weight of the absorbed water of the suspended column and retaining the dry tensile strength in the treated portions. Since this treatment only retards the

wetting of said region, the paper retains the ability to be easily dispersed upon flushing. It is preferred that the treated paper have the ability to form a substantially continuous conductive path for the

urine stream so that the urine does not fall away from the paper and splash in the toilet.

[0016] Additional strength can be added to conventional toilet papers by using a band of reinforcing material such as polymeric

adhesive binders, such as is taught in U.S. Pat. No. 4,117,187, by

embossing or compressing a band of the web while wet, or by other

processing or manufacturing technologies well known for strengthening such papers. The paper may also be strengthened sufficiently to function in this invention by simply strengthening the entire web, for example by using fibers of the desired length and denier to provide sufficient wet tensile strength to support the urine column, or through chemical treatments as is taught in U.S. Pat. No. 3,546,755. However, this also lengthens the time required for dispersal upon flushing. This time may be reduced by restricting reinforcing materials, such as is taught in U.S. Pat. No. 4,755,421, to a

narrow band running along the length of the paper. Alternatively, in the case of two-ply papers, one of the

layers may be separately treated or manufactured to be slightly stronger or

water repellent, leaving the other layer unchanged. In the case where the layer is made to be water resistant, there is an additional benefit in that the water resistant layer protects the user's fingers from contact with liquids while the absorbent layer still functions normally during ordinary use.

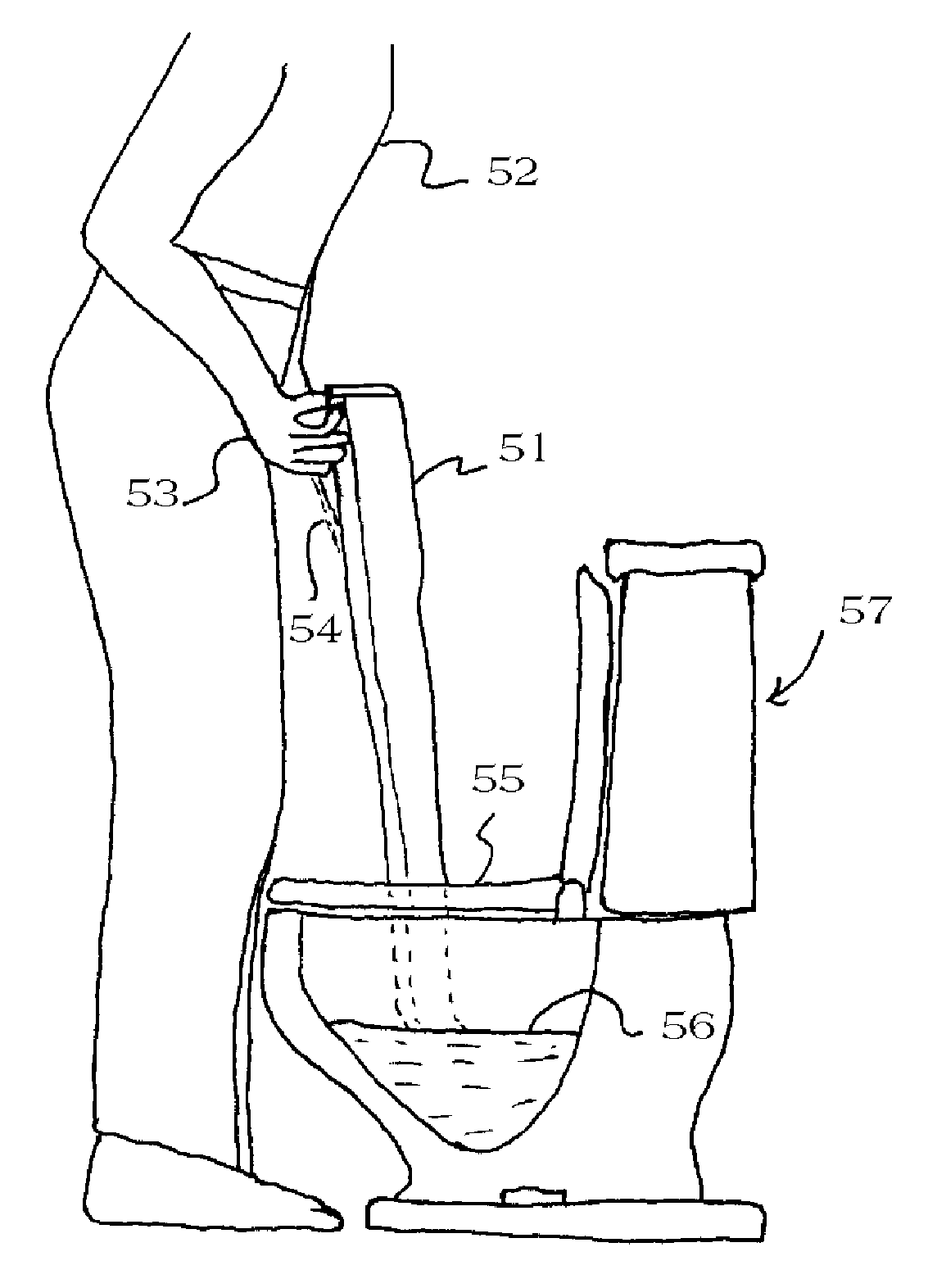

[0017] The urinary aid of the present invention must act both as a consolidator of the urine stream as well as a guide leading directly from, or in close proximity to, the

urethra and into, or in close proximity to, the water of the toilet bowl. For males, the aid is held a

short distance, e.g. about one inch, in front of and a

short distance above the downward directed

penis, or draped over the end of the

penis. The guide is of sufficient width to be held with the fingers in a semicircle in front of and above, or on each side of, the

penis. Upon urination, the urine almost immediately encounters the aid, preferably at an

oblique angle, which consolidates all of the ‘

satellite drops’ into one urine stream and accurately conducts the stream of urine down the aid into the toilet bowl, thereby eliminating both the splashing and

noise from the stream entering the toilet bowl. After use, the aid is dropped into the toilet and flushed. The fingers do not become wet, since the rate of transport of urine upward in the urinary aid via

capillary action is not sufficiently rapid. Females may also benefit from this urinary aid when seated on a toilet to reduce

noise in some settings or when used in conjunction with collection devices facilitating urination from a standing position, such as disclosed in U.S. Pat. No. 6,547,771 or U.S. Pat. No. 6,202,225. The result is to ensure that the toilet extremities, the surrounding area and the toilet seat will remain clean even if left in its lowered position.

[0018] The urinary aid according to the present invention could be easily substituted ubiquitously for ordinary toilet paper. The roll can be easily marked so as to identify it as being a paper suitable for use as described herein. The specially modified toilet paper of the present invention is of inexpensive manufacture, thereby making it eminently affordable and providing the broadest possible market. Finally, all of the aforesaid advantages and objectives of the present invention are achieved without incurring any substantial relative

disadvantage as the toilet paper can be used conventionally without loss of

efficacy.

Login to View More

Login to View More  Login to View More

Login to View More