Metal wire coated with a layer of metal material intended to reinforce elastomeric materials and methods for producing the same

a technology of elastomeric materials and metal wires, which is applied in the direction of vacuum evaporation coating, coating, manufacturing tools, etc., can solve the problems of excessive number of steps, unresolved, and excessive duration of the above-mentioned diffusion step, and achieves high quality, improved corrosion resistance, and suitable mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

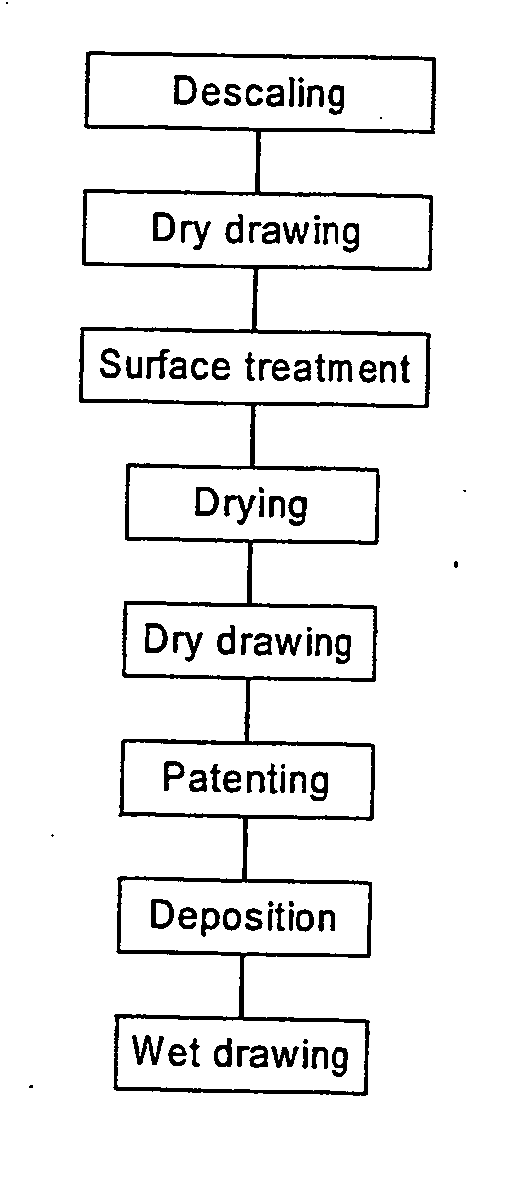

[0155] A steel wire rod, having a diameter of about 5.5 mm, was subjected to a descaling step and to a dry drawing—at the end of which the wire core having an initial diameter equal to about 1.4 mm was obtained—in a substantially continuous manner.

[0156] Subsequently, an electrolytically pickling of the core with sulfuric acid was carried out. In particular, the core was pickled by conveying the same in a sulfuric acid bath arranged downstream of the descaling position in a substantially continuous manner. The core was successively washed by conveying the core in water, said washing step being provided downstream of the pickling bath.

[0157] Successively, a patenting thermal treatment of the core, consisting of a heating step in a furnace at a temperature of about 950° C. and of a subsequent cooling step in air at a temperature of about 550° C., was carried out in a substantially continuous manner. The exit rate of the core from the furnace was equal to about 36 m / min.

[0158] Subse...

example 2

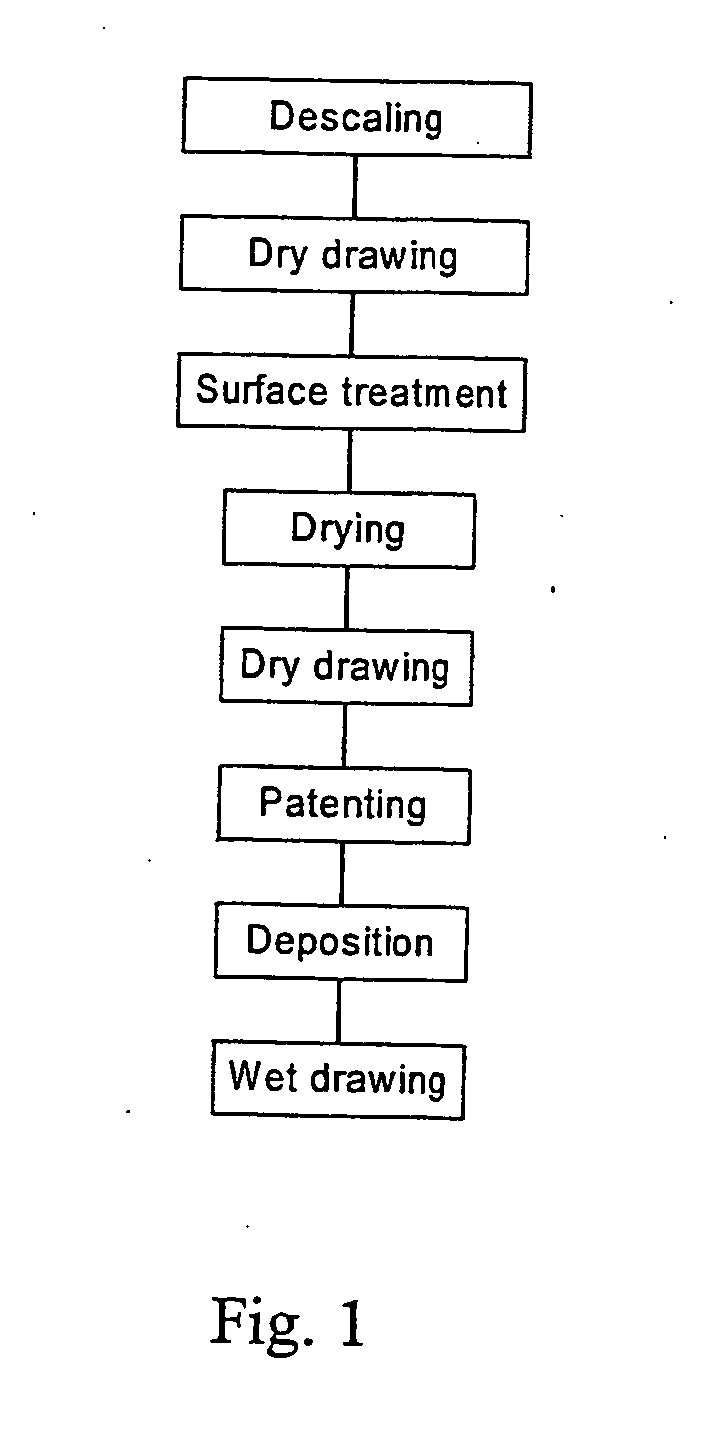

[0172] A steel wire rod, having a diameter of about 5.5 mm, was subjected to a descaling step as in Example 1.

[0173] After the descaling step, an electrolytically pickling of the wire rod with sulfuric acid and a subsequent washing in water were carried out as described in Example 1.

[0174] The rod so pickled and washed was dried and submitted to a dry drawing—at the end of which a wire core having an initial diameter equal to about 1.4 mm was obtained—in a substantially continuous manner.

[0175] Successively, a patenting thermal treatment, a deposition and a wet drawing step were carried out as described in Example 1.

[0176] A further stranding step of a plurality of steel wires coated with brass obtained as described above was provided to obtain a cord reinforcing elastomeric materials, such as for example the belt layers of a tire.

[0177] In a way known per se, cords produced in accordance with the method of the invention were incorporated in articles of elastomeric materials, s...

example 3

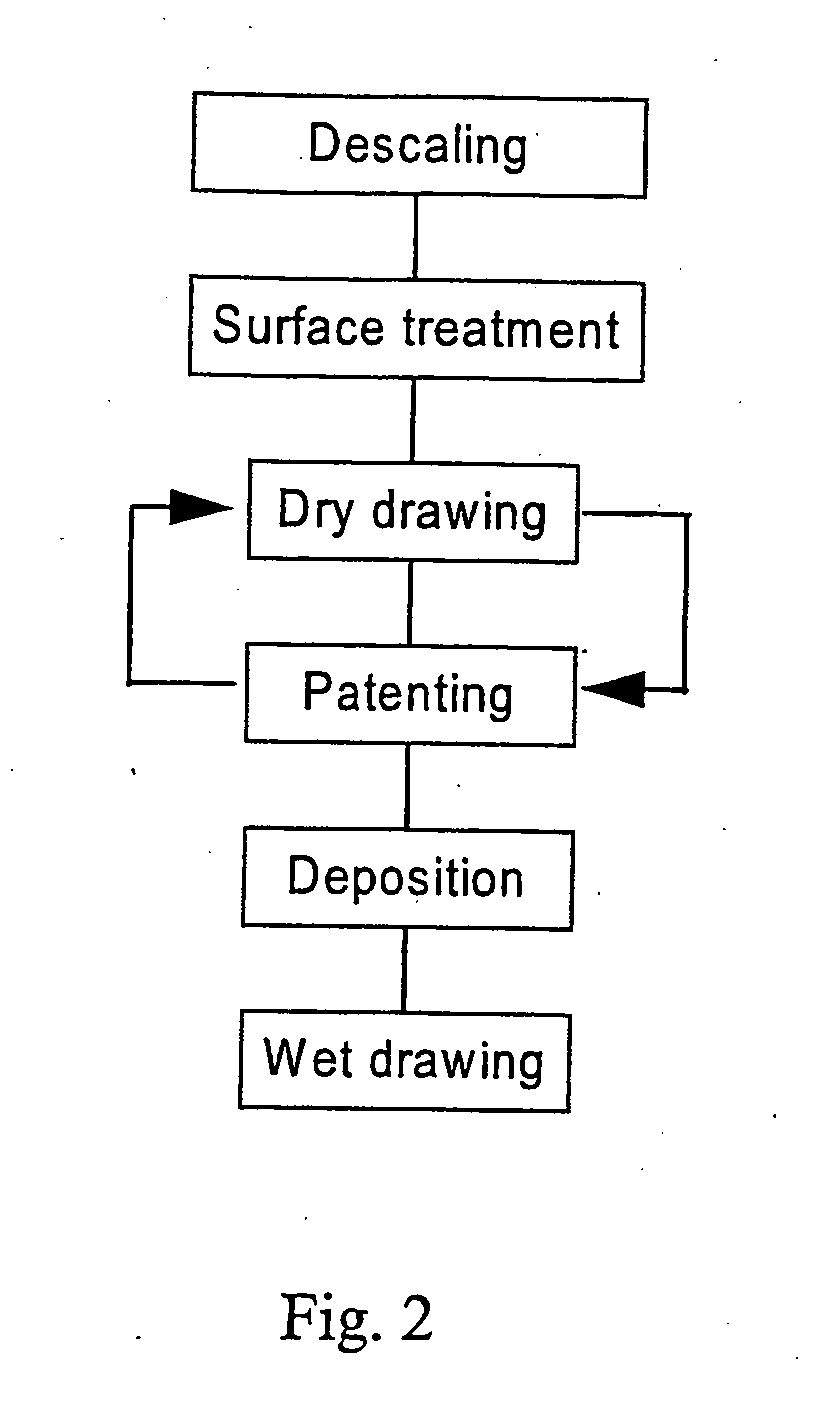

[0178] A core of steel wire having an initial diameter equal to about 1.4 mm was obtained as described in Example 1.

[0179] Subsequently, the steel core was superficially treated and patented as described in Example 1.

[0180] The exit rate of the core from the furnace was equal to about 36 m / min.

[0181] The steel core was fed into a first pre-chamber and then into a vacuum deposition chamber as described in Example 1, with the exception that the vacuum deposition chamber comprised a plurality of rectangular-shaped cathodes (45 cm×7 cm), consisting of brass having a copper content of 63.5% by weight and 36.5% by weight of zinc. The steel core was fed in a substantially continuous manner into such a vacuum deposition chamber at a speed of about 36 m / min and a brass coating layer having an initial thickness equal to about 1.5 μm was then deposited on the steel core in a substantially continuous manner by means of the magnetron sputtering technique.

[0182] For such a purpose, after a pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| speed | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com