Ultracryostat and frigidity supplying apparatus

a technology of supplying apparatus and insulating chamber, which is applied in the direction of indirect heat exchangers, domestic cooling devices, lighting and heating devices, etc., can solve the problems of large structural distortion, insufficient heat shields, and insufficient signal to noise ratios, so as to avoid heat flow back

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

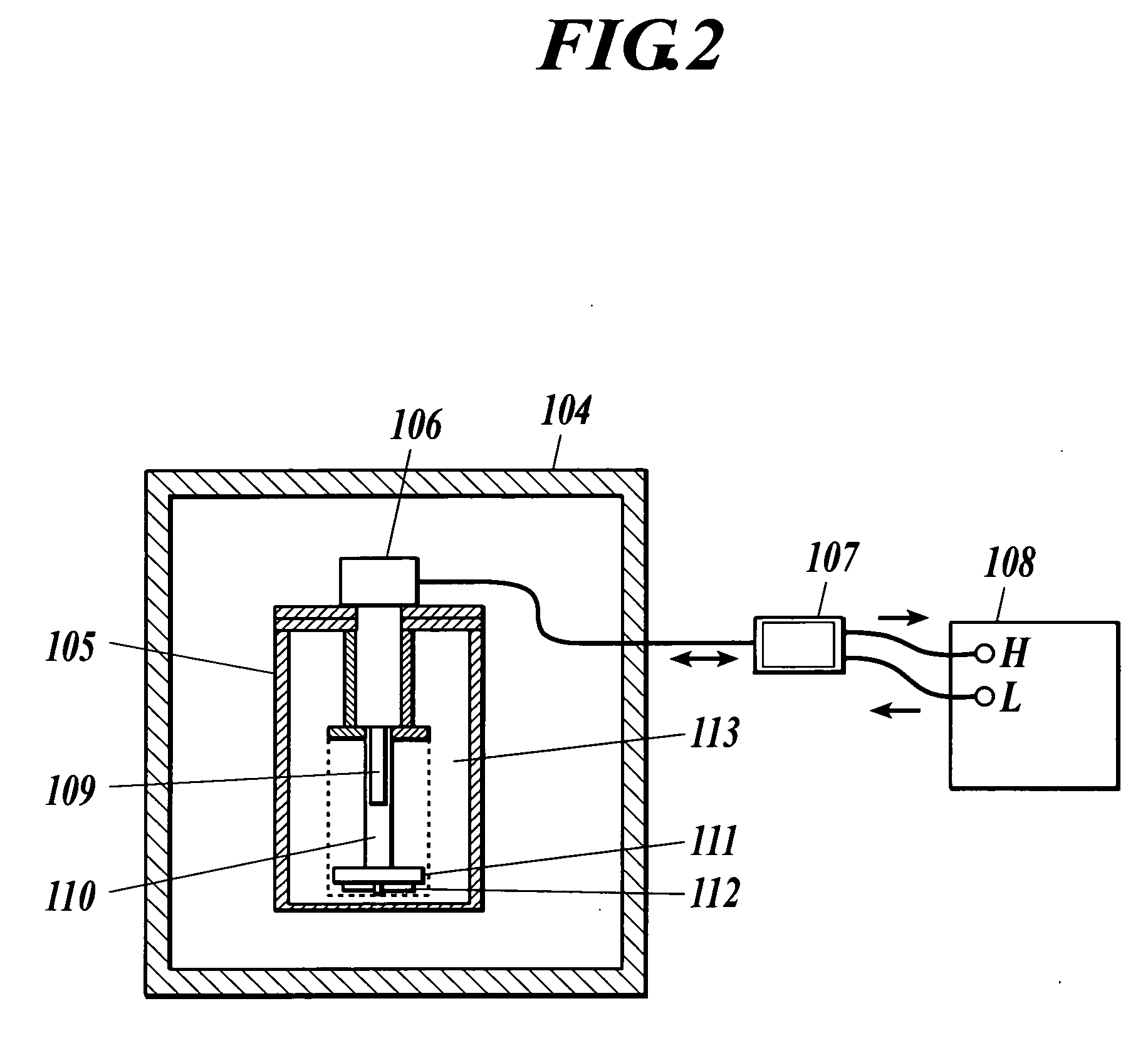

embodiment 1

[0034] The feature of the invention is that the heat pipe having thermally variable conductance, i.e. having variable thermal conductivity, connects the cryocooler as the frigidity generating member with the thermal anchor continued to the radiation shield of the cryostat which requires the frigidity.

[0035] That is, by using the heat pipe which can switch frigidity transporting effect, frigidity conducts from the cryocooler to the thermal anchor when the cryocooler is ON, and heat does not conduct from the cryocooler to the thermal anchor when the cryocooler is OFF.

[0036] Here, for the following explanation, the frigidity designates an absorption of heat and has opposite meaning of heat diffusion or heat flow. Further, a high pressure supplying pipe and gas compressor and the like included in the cryocooler are omitted.

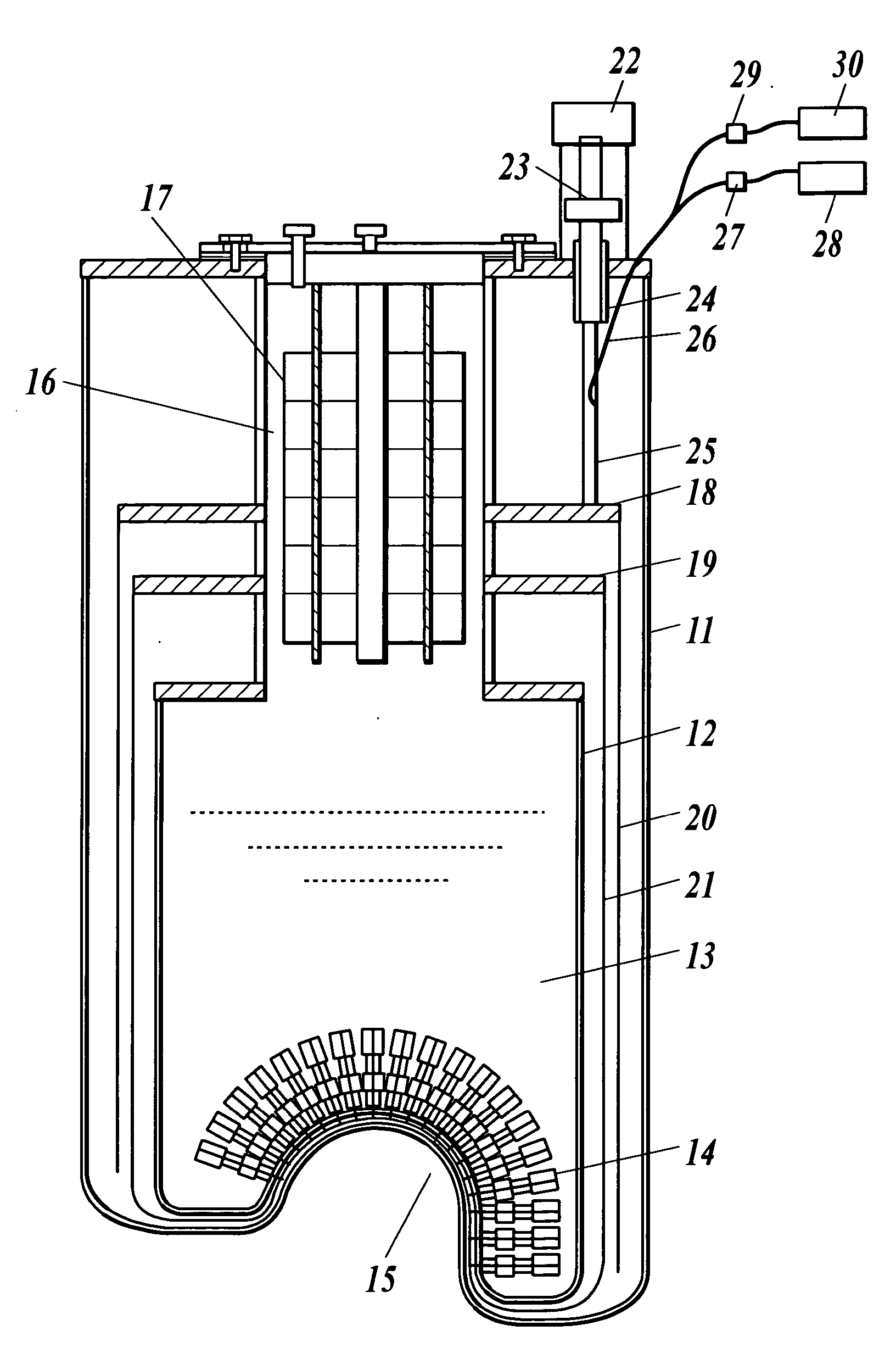

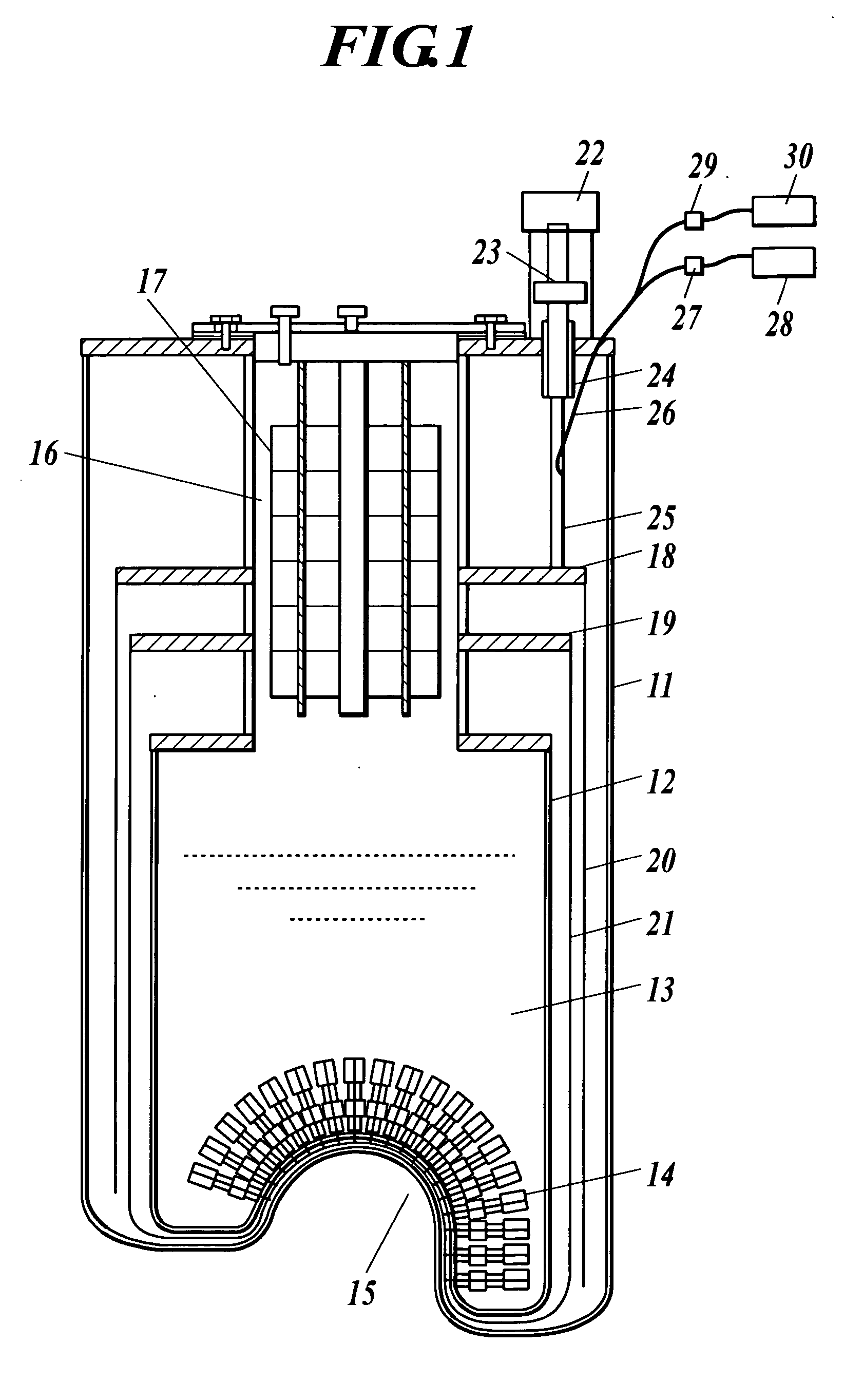

[0037]FIG. 1 is a whole constitution of the ultracryostat of the invention, and shows an embodiment in which the cryocooler is connected to the cryostat through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com