Lithographic printing plate support, method of manufacturing the same, and presensitized plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0324] Hereinafter, the present invention is described in detail by way of examples. However, the present invention is not limited thereto.

Examples and Comparative Examples of First to Tenth Aspects of Invention

1-1. Preparation of Aluminum Melt

[0325] Aluminum Melts 1 to 7 containing various ingredients in the amounts shown in Table 1, with the balance being aluminum and inadvertent impurities, were prepared.

TABLE 1SiCuTiBMgMnZnAl meltFe (wt %)(wt %)(wt %)(wt %)(wt %)(wt %)(wt %)(wt %)10.060.030.0010.0050.0010.0010.0010.00120.280.050.0020.0100.0020.0010.0010.00130.280.080.0150.0100.0020.0010.0010.00140.280.080.0250.0100.0020.0010.0010.00150.280.080.0350.0100.0020.0010.0010.00160.280.080.0010.0050.0010.2500.0010.00170.280.200.0030.0300.0060.2500.9000.050

1-2. Manufacture of Lithographic Printing Plate Support

examples 57 and 58

, and Comparative Examples 21 to 24

[0489] Cleaning treatment was carried out on the aluminum melts obtained as described above, following which, as shown in Table 8, the respective melts were consecutively subjected to a filtration step, a continuous casting step, a cold rolling step, an intermediate annealing step, a finish cold rolling step, a graining treatment step and an anodizing treatment step by the methods described below, thereby obtaining lithographic printing plate supports.

(1) Filtration Step:

[0490] The aluminum melt was filtered using a filtration tank. The filter used in the filtration tank was a ceramic filter. A filtration step was not carried out in Comparative Examples 22 and 24.

(2) Continuous Casting Step:

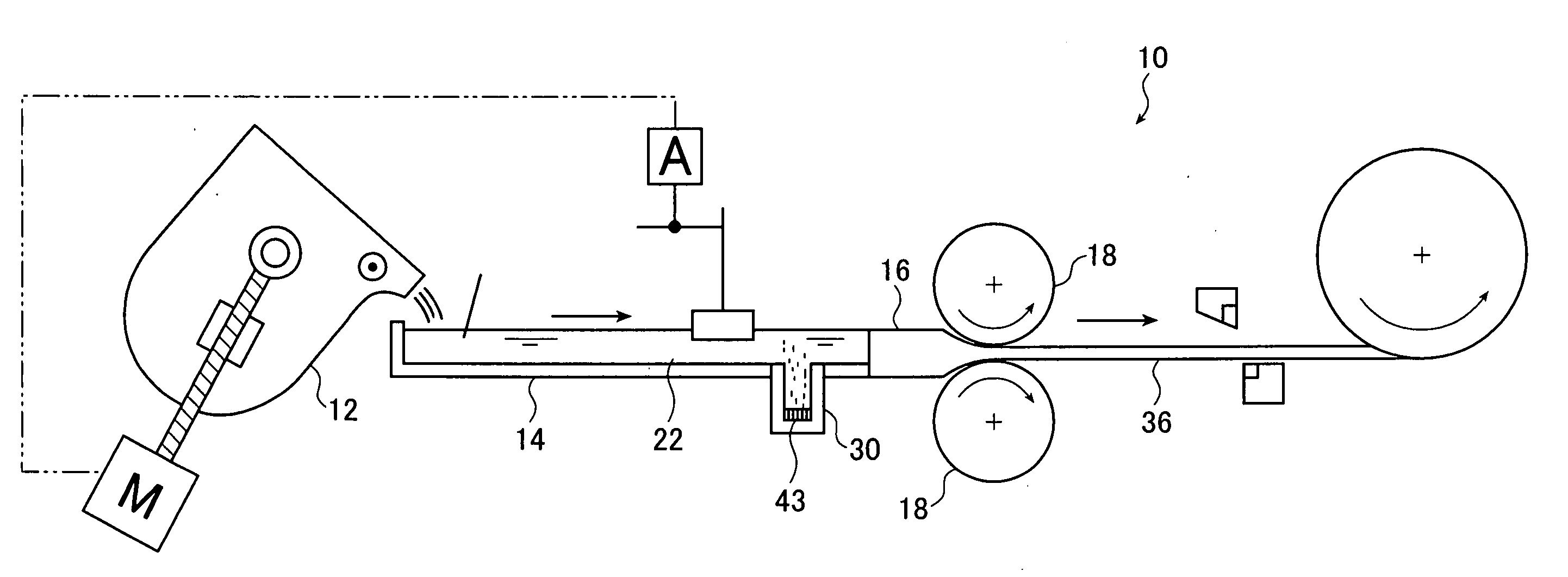

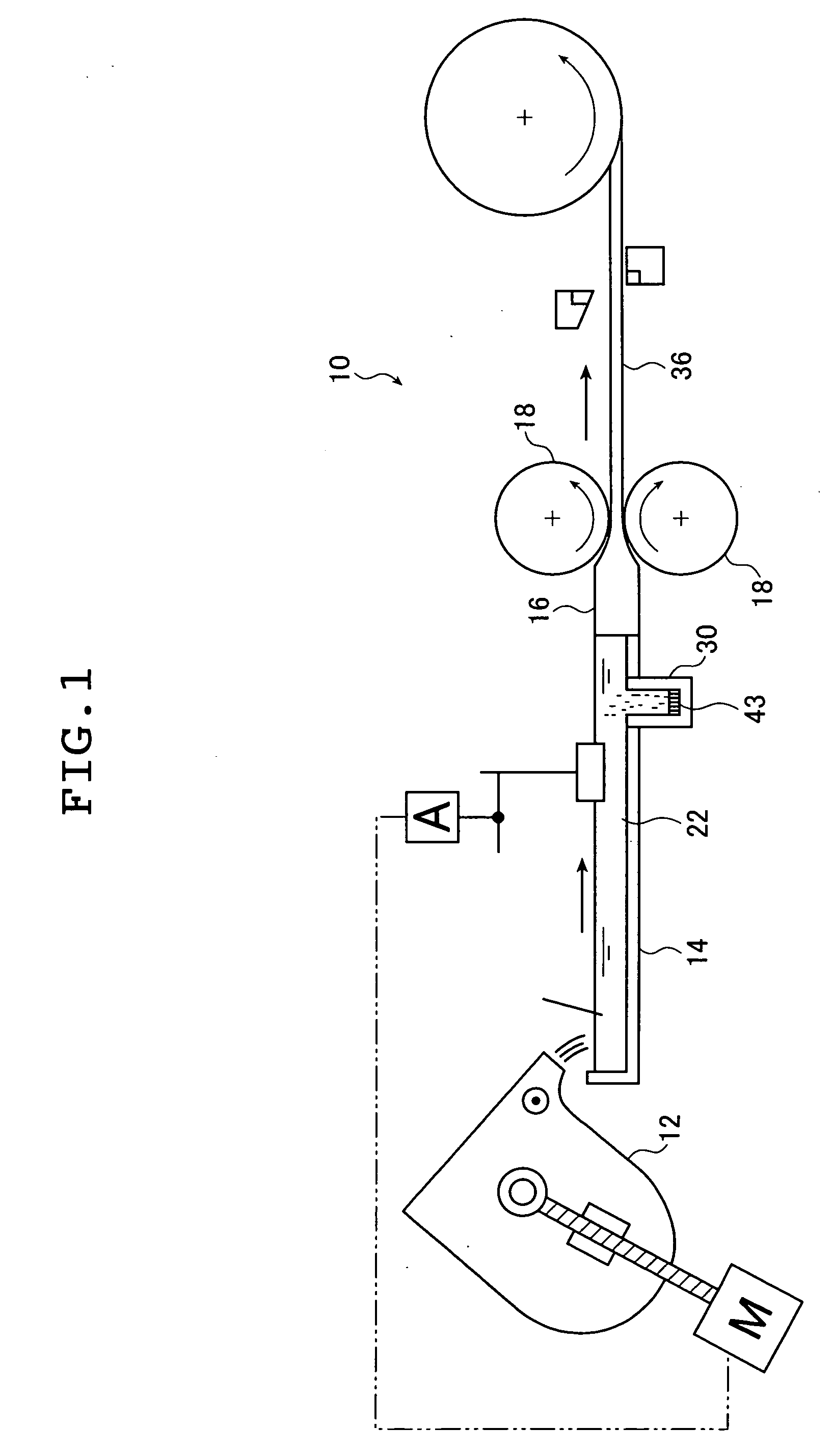

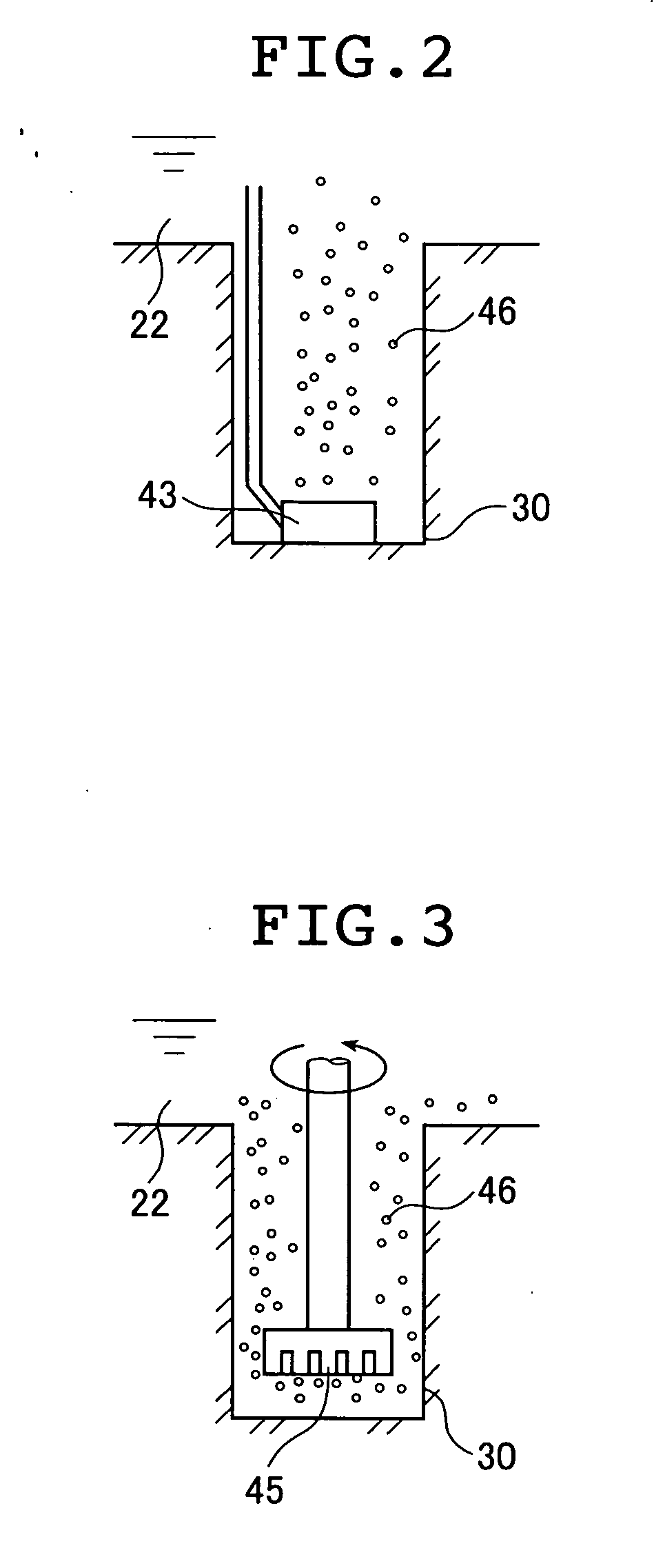

[0491] Aluminum alloy plates were continuously cast using the machine shown in FIG. 1. Casting was continued without interruption by feeding additional aluminum melt from a melting furnace (not shown) just before the melt in the holding furnace ran out. Mo...

examples 59 and 60

, and Comparative Examples 25 and 26

[0509] Cleaning treatment was carried out on the aluminum melts obtained as described above, following which, as shown in Table 9, the respective melts were consecutively subjected to a continuous casting step, a cold rolling step, an intermediate annealing step, a finish cold rolling step, a graining treatment step and an anodizing treatment step by the methods described below, thereby obtaining lithographic printing plate supports. A filtration step was not carried out prior to the continuous casting step.

(1) Continuous Casting Step:

[0510] Aluminum alloy plates were continuously cast using the machine shown in FIG. 1. More specifically, first, in a melt feeding step, the aluminum melt was fed from a melting furnace to a melt feed nozzle. Agitation was not carried out at this time. Next, in a casting step, the aluminum melt was fed between a pair of cooling rollers from the melt feel nozzle, then was rolled while being solidified by the pair o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com