Catalyst composition for production of rigid polyurethane foam and isocyanurate-modified rigid polysurethane foam and raw-material composition containing the same

a technology of rigid polyurethane foam and catalyst composition, which is applied in the direction of catalyst composition for production of rigid polyurethane foam and isocyanuratemodified rigid polyurethane foam and raw material composition containing the same, can solve the problems of deteriorating surface brittleness, insufficient adhesiveness to face materials, and reducing storage stability, so as to enhance the storage stability of raw material-blended composition, inhibit hydrolysis, and improve the hydrolysis of polyester polyol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

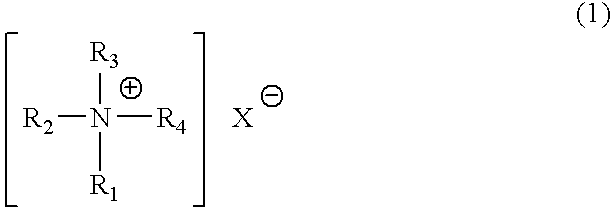

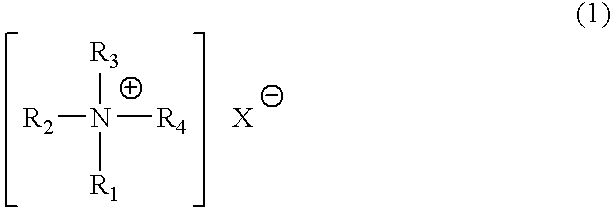

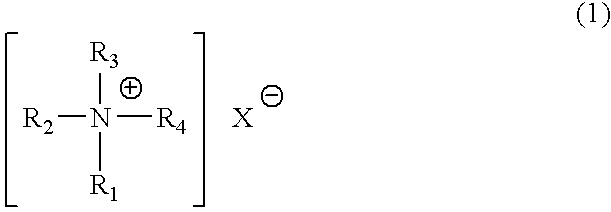

Method used

Image

Examples

preparation example 1

Production of Catalyst Al (Solution of 50% of tetraethylammonium acetate and 50% of ethylene glycol)

[0091] An aqueous tetraethylammonium hydroxide solution (1 mol) was charged into a flask and, while the solution was cooled so as to maintain it at room temperature, acetic acid (1 mol) was added thereto to obtain a tetraethylammonium acetate salt. Thereafter, ethylene glycol was added as a solvent so as to be a predetermined concentration and then water was removed by evaporation using an evaporator to obtain a solution of 50% of tetraethylammonium acetate and 50% of ethylene glycol.

preparation example 2

Production of Catalyst A2 (Solution of 50% of tetramethylammonium acetate and 50% of ethylene glycol)

[0092] A solution of 50% of tetramethylammonium acetate and 50% of ethylene glycol was obtained in the same manner as in Preparation Example 1 except that an aqueous tetramethylammonium hydroxide solution (1 mol) was used instead of the aqueous tetraethylammonium hydroxide solution.

preparation example 3

Production of Catalyst A3 (Solution of 50% of tetramethylammonium formate and 50% of ethylene glycol)

[0093] A solution of 50% of aqueous tetramethylammonium formate and 50% of ethylene glycol was obtained in the same manner as in Preparation Example 2 except that formic acid (1 mol) was used instead of acetic acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydrophobicity | aaaaa | aaaaa |

| Storage stability | aaaaa | aaaaa |

| Acid dissociation constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com