Silicon wafer and method for production of silicon wafer

a technology of silicon wafers and silicon wafers, which is applied in the direction of transportation and packaging, rigid containers, packaging, etc., can solve the problems of short life, short life, and reduced gettering ability, so as to prevent device malfunctions and prolong product life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

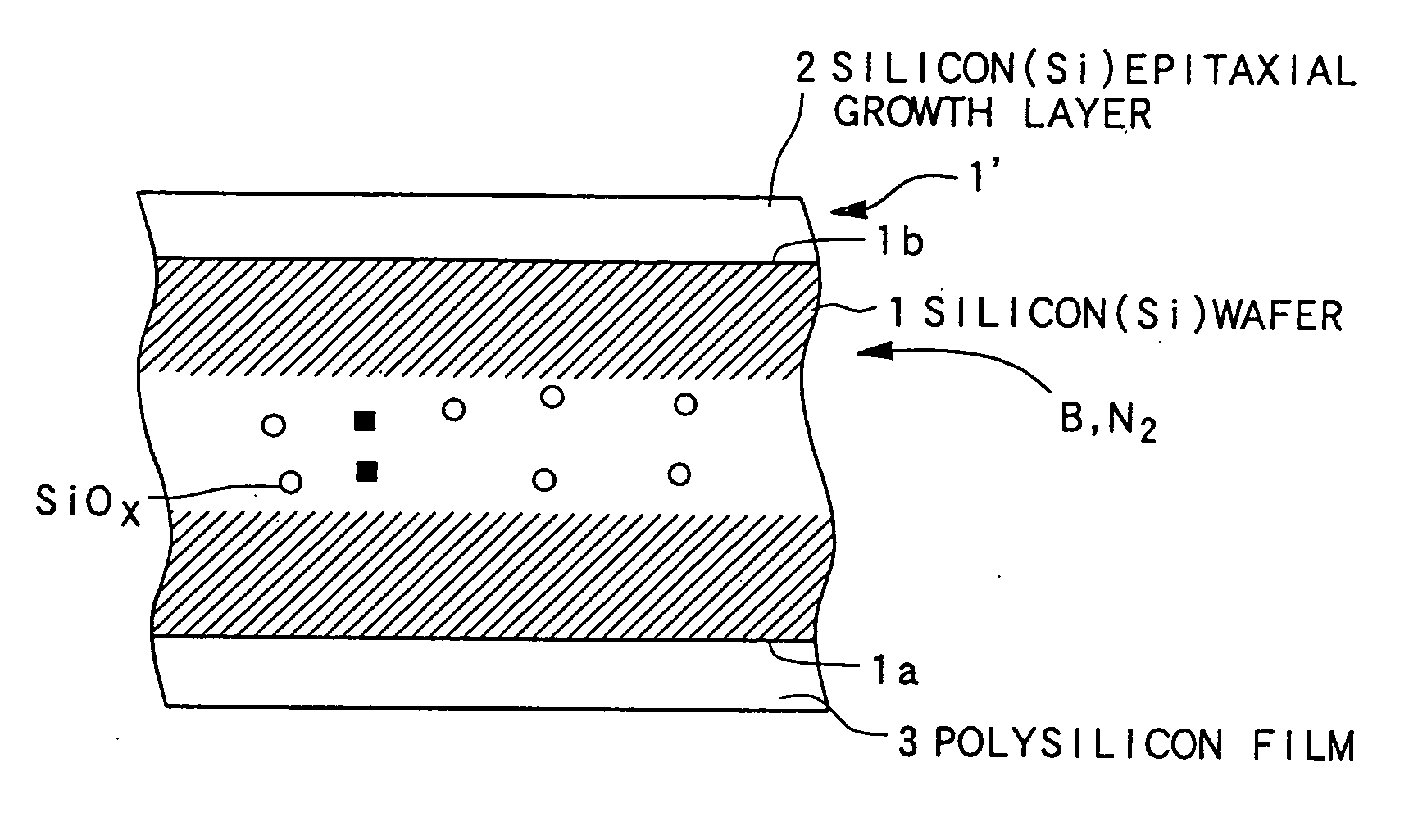

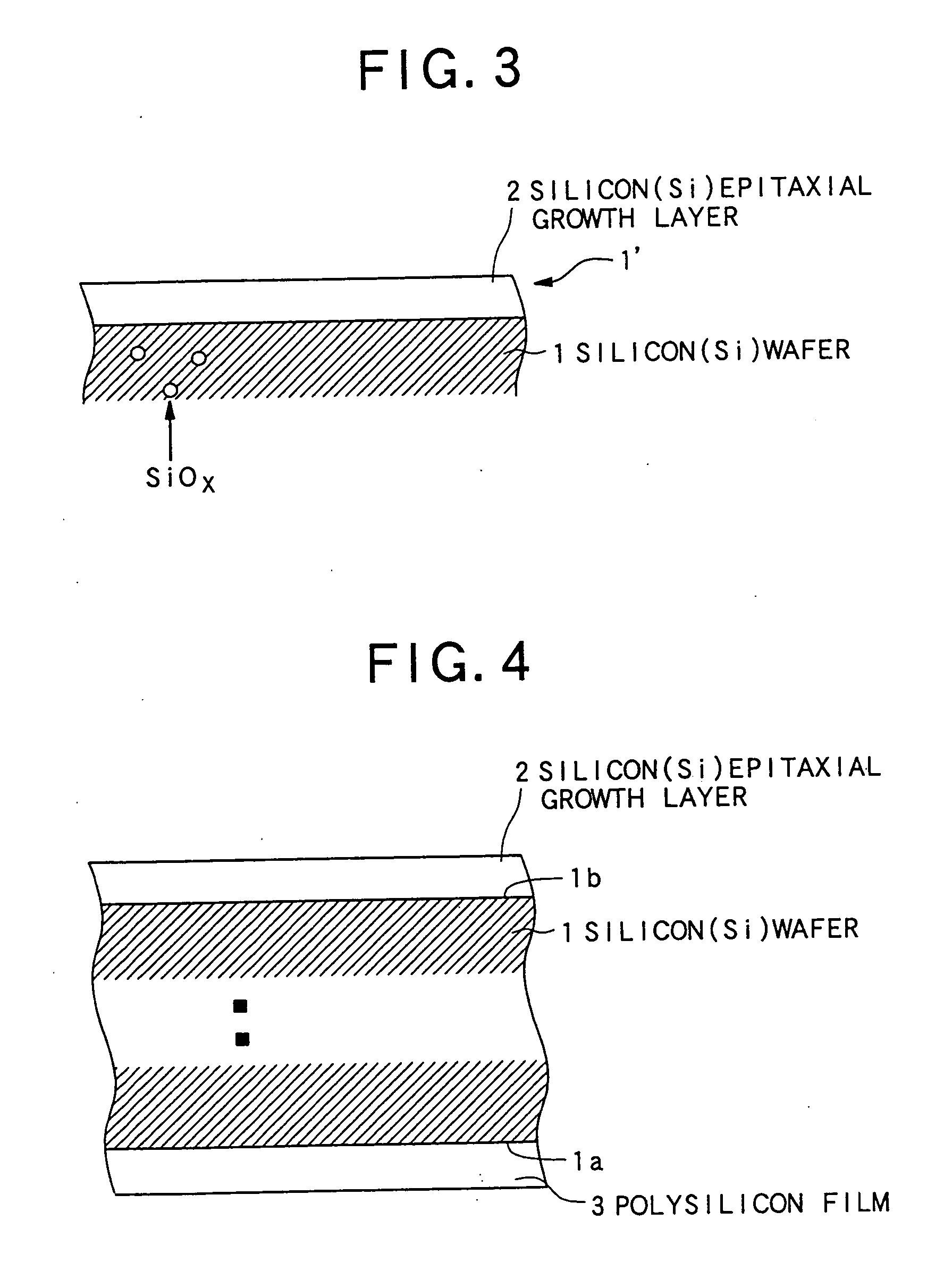

[0042] A semiconductor wafer and a method for manufacturing a semiconductor wafer according to embodiment of the present invention will be described in reference to the accompanying drawings.

[0043] In the embodiment described below, a silicon wafer is employed as the semiconductor wafer.

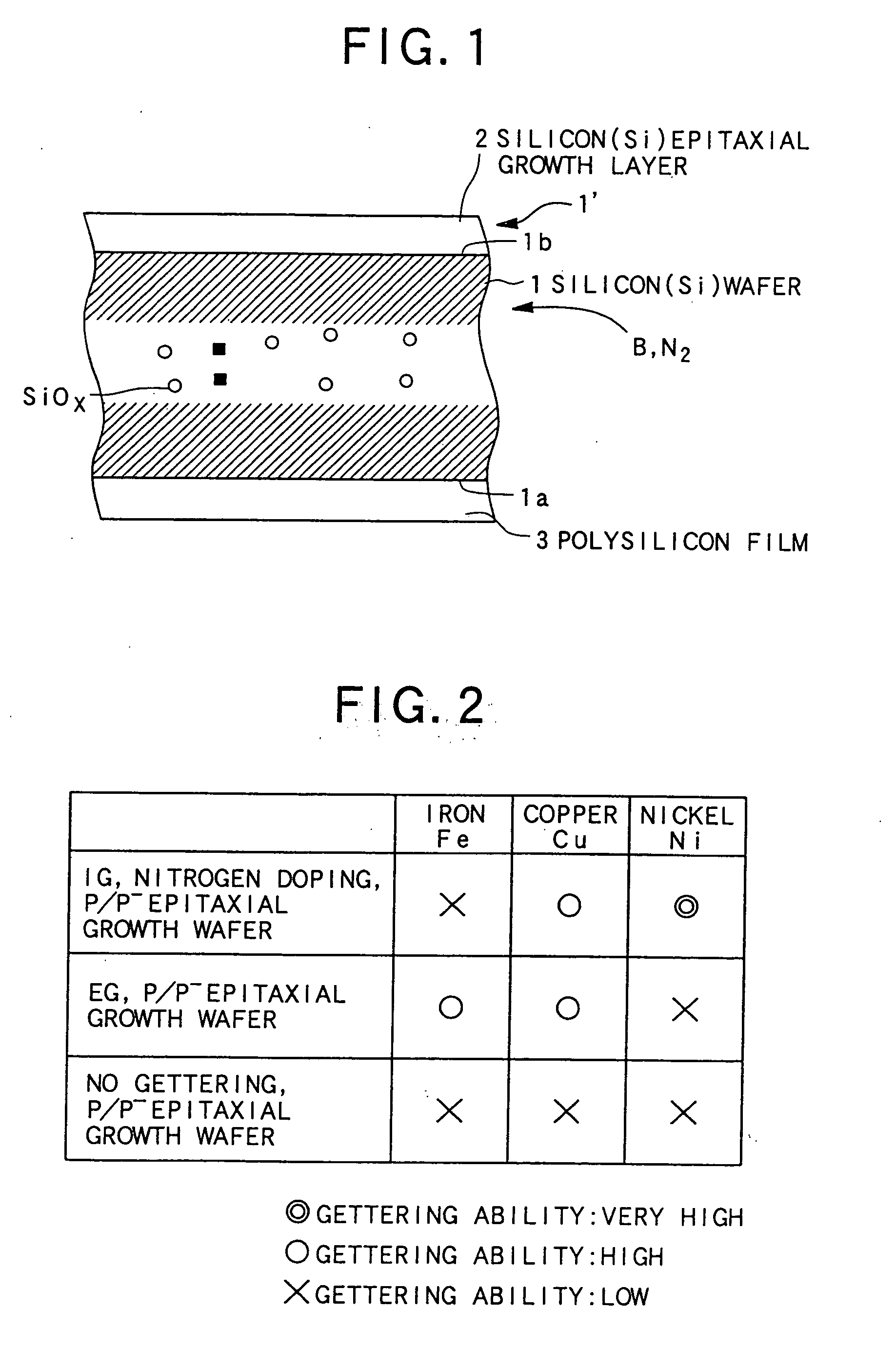

[0044] In view of the situation in which the gettering abilities is insufficient in both the IG additionally including the nitrogen doping process and the EG treatment, the present inventors have conducted the analysis on the basis of the assumption that the gettering abilities of the EG and the IG vary depending on the type of heavy metal ions. The results of the analysis are shown FIG. 2. Here, the silicon wafer that was analyzed was a p / p− silicon wafer 1′ doped with boron of a low concentration. The term “low concentration” is meant to be a concentration of boron within a range of approximately from 3×1014 / cm3 to 1×1016 / cm3 (1 Ω-cm to 15 Ω-cm).

[0045]FIG. 2 shows the results obtained by the ana...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com