Hydrogen generation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

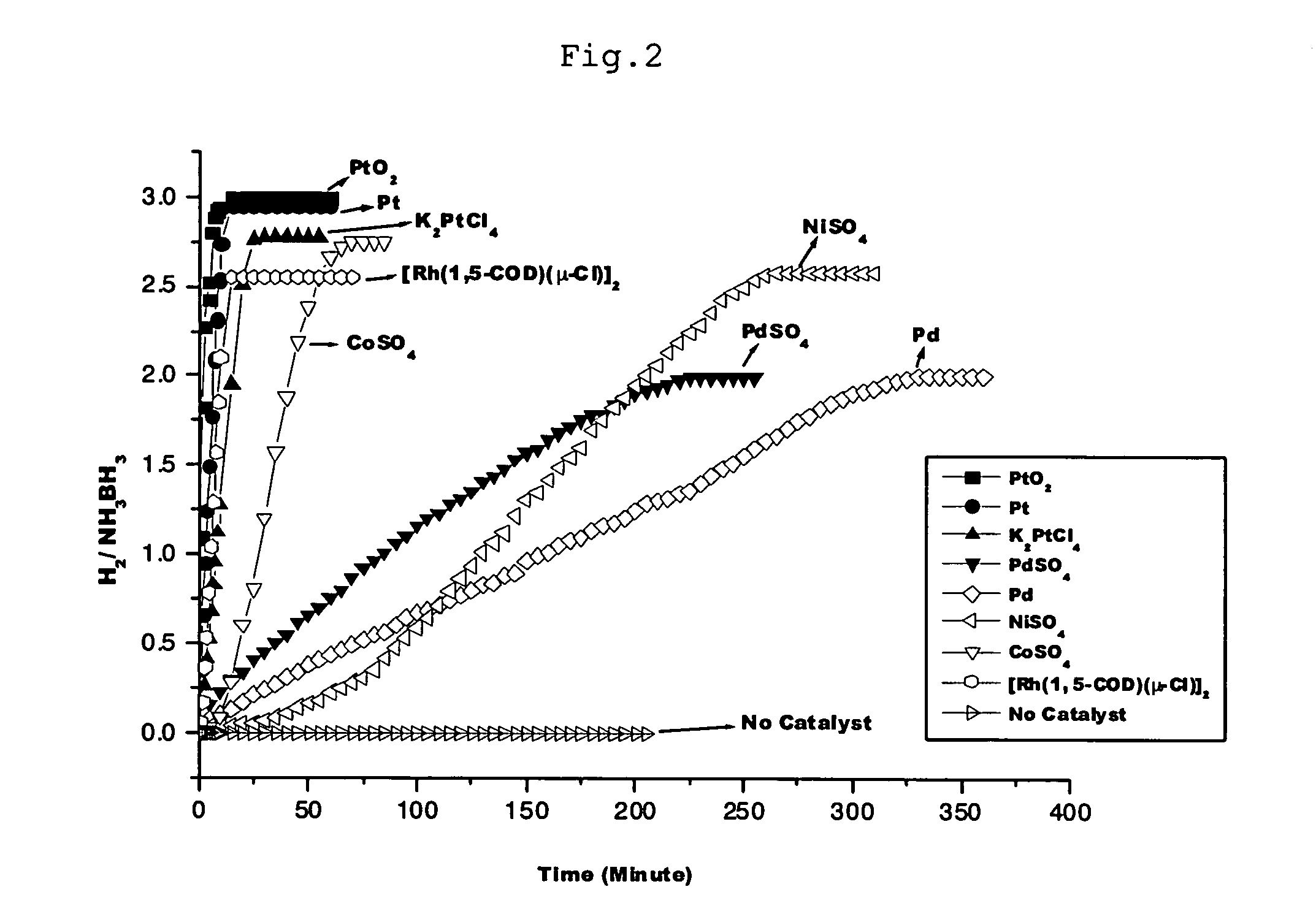

[0081]4.0 mg of platinum oxide (PtO2) powder was placed in a 30 ml two-necked flask. A gas burette was connected to one neck and a 50 ml dropping funnel with pressure-equalizing arm was connected to the other neck. 15 ml of aqueous solution in which 50 mg of ammonia borane (NH3BH3, 90% purity) was dissolved was placed in the dropping funnel.

[0082] The inside of the system was evacuated with a vacuum pump, and then filled with argon gas. The aqueous ammonia borane solution was introduced from the dropping funnel into the two-necked flask, and stirring was conducted at room temperature. One minute after stirring was started, it was observed that 39 ml of gas had been released; two minutes after, 65 ml; 5 minutes after, 87 ml; 10 minutes after, 105 ml; and 30 minutes after, 107 ml.

[0083] Gas chromatographic (GC) and mass spectral (MS) analyses showed that the gas released was hydrogen. The amount of hydrogen released was 3 moles per mole of ammonia borane (NH3BH3) as a starting mater...

example 2

[0085]4.0 mg of platinum (Pt) powder was placed in a 30 ml two-necked flask. A gas burette was connected to one neck and a 50 ml dropping funnel with pressure-equalizing arm was connected to the other neck. 15 ml of aqueous solution in which 50 mg of ammonia borane (NH3BH3, 90% purity) was dissolved was placed in the dropping funnel.

[0086] The inside of the system was evacuated with a vacuum pump, and then filled with argon gas. The aqueous ammonia borane solution was introduced from the dropping funnel into the two-necked flask, and stirring was conducted at room temperature. One minute after stirring was started, it was observed that 12.5 ml of gas had been released; two minutes after, 23.5 ml; 5 minutes after, 53.5 ml; 10 minutes after, 97.5 ml; and 30 minutes after, 105 ml.

[0087] Gas chromatographic (GC) and mass spectral (MS) analyses showed that the released gas was hydrogen. The amount of hydrogen released was 3 moles per mole of ammonia borane (NH3BH3) as a starting materi...

example 3

[0089] After the reaction of Example 2 was complete, platinum (Pt) powder was collected by filtration and placed in a 30 ml two-necked flask. A gas burette was connected to one neck and a 50 ml dropping funnel with pressure-equalizing arm was connected to the other neck. 15 ml of aqueous solution in which 50 mg of ammonia borane (NH3BH3, 90% purity) was dissolved was placed in the dropping funnel.

[0090] The inside of the system was evacuated with a vacuum pump, and then filled with argon gas. The aqueous ammonia borane solution was introduced from the dropping funnel into the two-necked flask, and stirring was conducted at room temperature. One minute after stirring was started, it was observed that 11 ml of gas had been released; two minutes after, 22 ml; 5 minutes after, 51 ml; 10 minutes after, 97 ml; and 30 minutes after, 105 ml.

[0091] Gas chromatographic (GC) and mass spectral (MS) analyses showed that the released gas was hydrogen. The amount of hydrogen released was 3 moles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com