Ferroelectric capacitor and method for fabricating the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0027]A ferroelectric capacitor and its fabrication method according to a first embodiment of the present invention will be described.

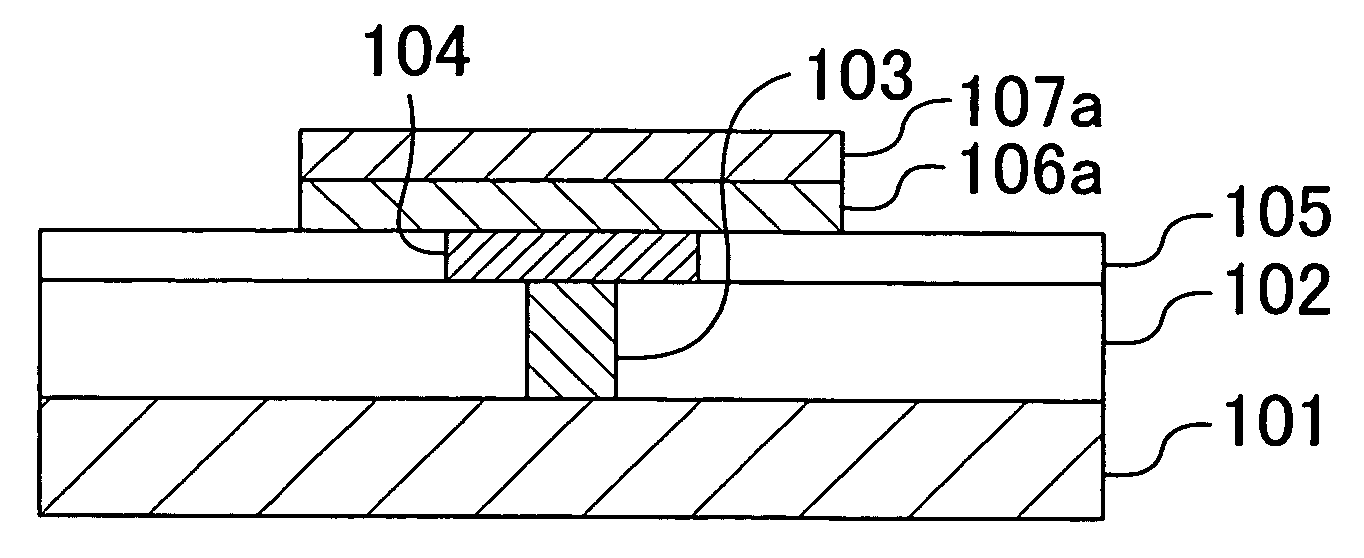

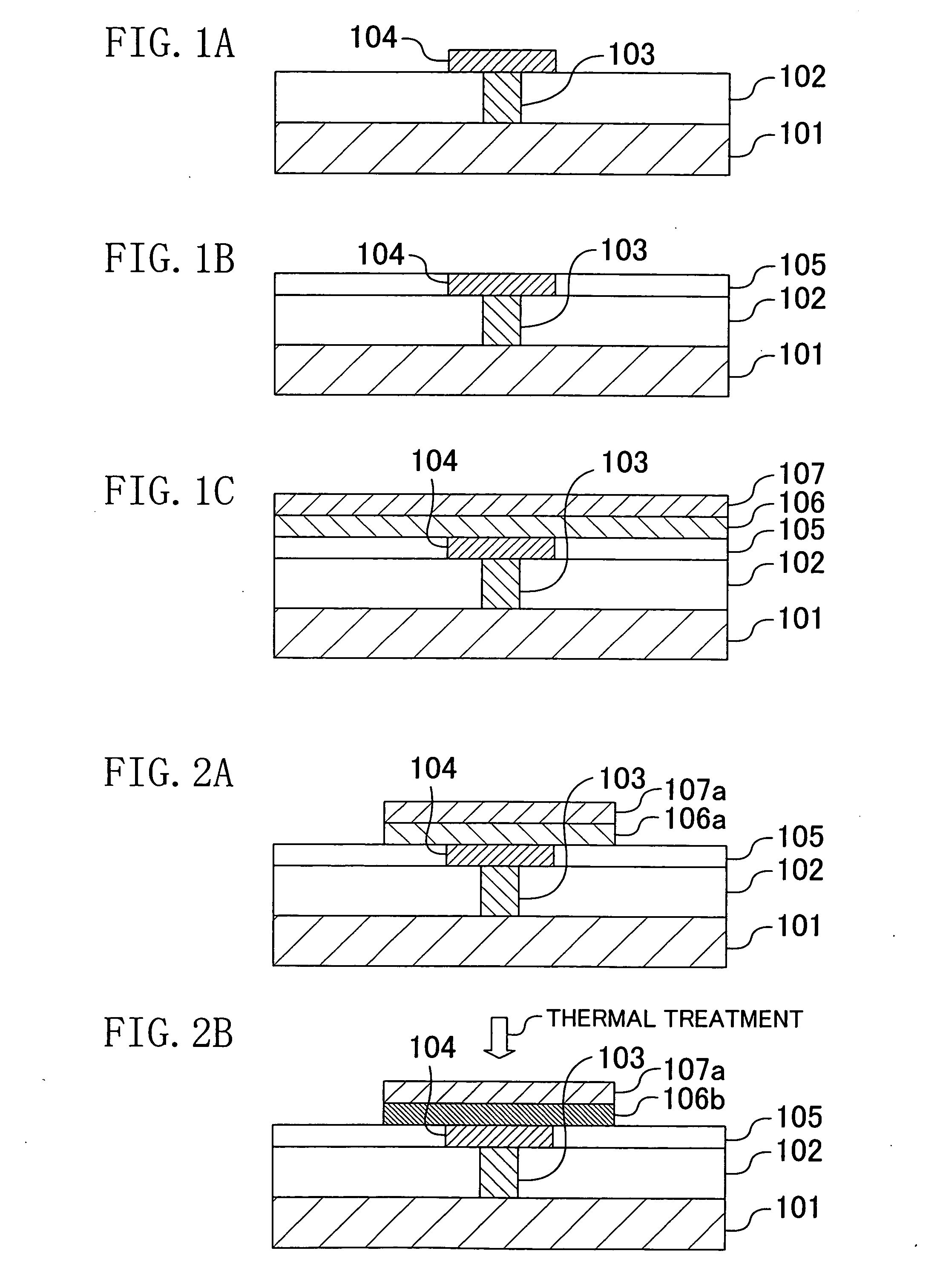

[0028]FIGS. 1A to 1C and 2A and 2B are sectional views showing a method for fabricating a ferroelectric capacitor according to the first embodiment of the present invention in the order of its fabrication process steps.

[0029]Referring to FIG. 1A, on a semiconductor substrate 101 with memory cell transistors (not shown) and the like formed thereon, a first interlayer insulating film 102 is formed which is made of, for example, a BPSG (SiO2 with B, P, and the like added therein) film. Subsequently, the first interlayer insulating film 102 is formed with a contact plug 103 of tungsten, polysilicon, or the like whose bottom end reaches the top surface of the semiconductor substrate 101. Then, a lower electrode 104 made by sequentially stacking a barrier layer and a noble metal layer in this order is formed on the first interlayer insulating film 102. The ...

second embodiment

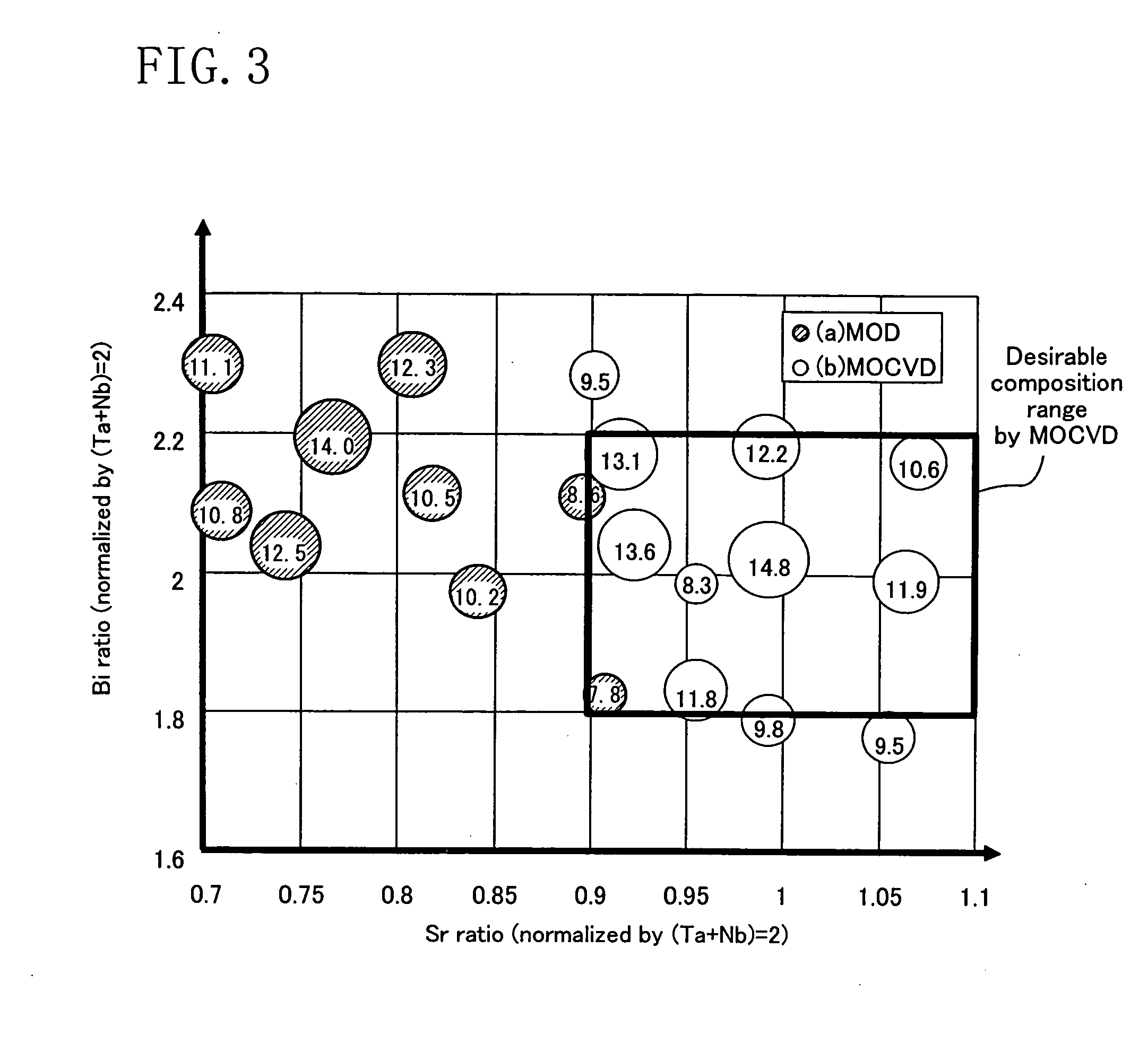

[0052]A second embodiment of the present invention will describe a fabrication method of a ferroelectric capacitor capable of providing an excellent percentage of polarization reversal relative to the thickness of a ferroelectric film as described above in the first embodiment. In the second embodiment, the description is divided according to materials constituting the ferroelectric film.

—Ferroelectric Film Made of SBTN—

[0053]FIGS. 5A to 5C and 6A and 6B are sectional views showing a fabrication method of a ferroelectric capacitor made of SBTN according to the second embodiment of the present invention in the order of its fabrication process steps.

[0054]Referring to FIG. 5A, on a semiconductor substrate 201 with memory cell transistors (not shown) and the like formed thereon, a first interlayer insulating film 202 is formed which is made of, for example, a BPSG (SiO2 with B, P, and the like added therein) film. Subsequently, the first interlayer insulating film 202 is formed with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com