Composition control for roll-to-roll processed photovoltaic films

a photovoltaic film and roll-to-roll technology, applied in the field of roll-to-roll processing photovoltaic films, can solve the problems of changing deposition rate, higher electricity generation cost of silicon-based solar cells, and higher cost of electricity generated by more traditional methods, and achieves better yield, lower cost, and high throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

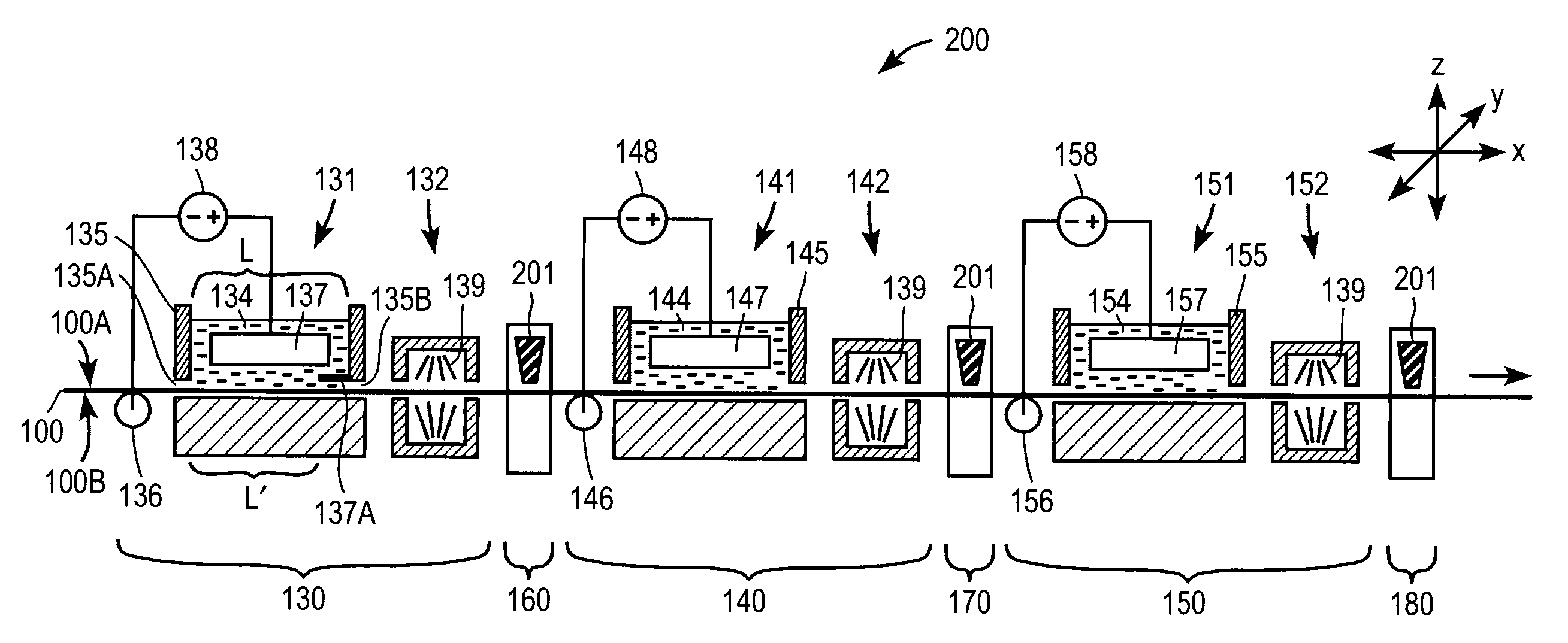

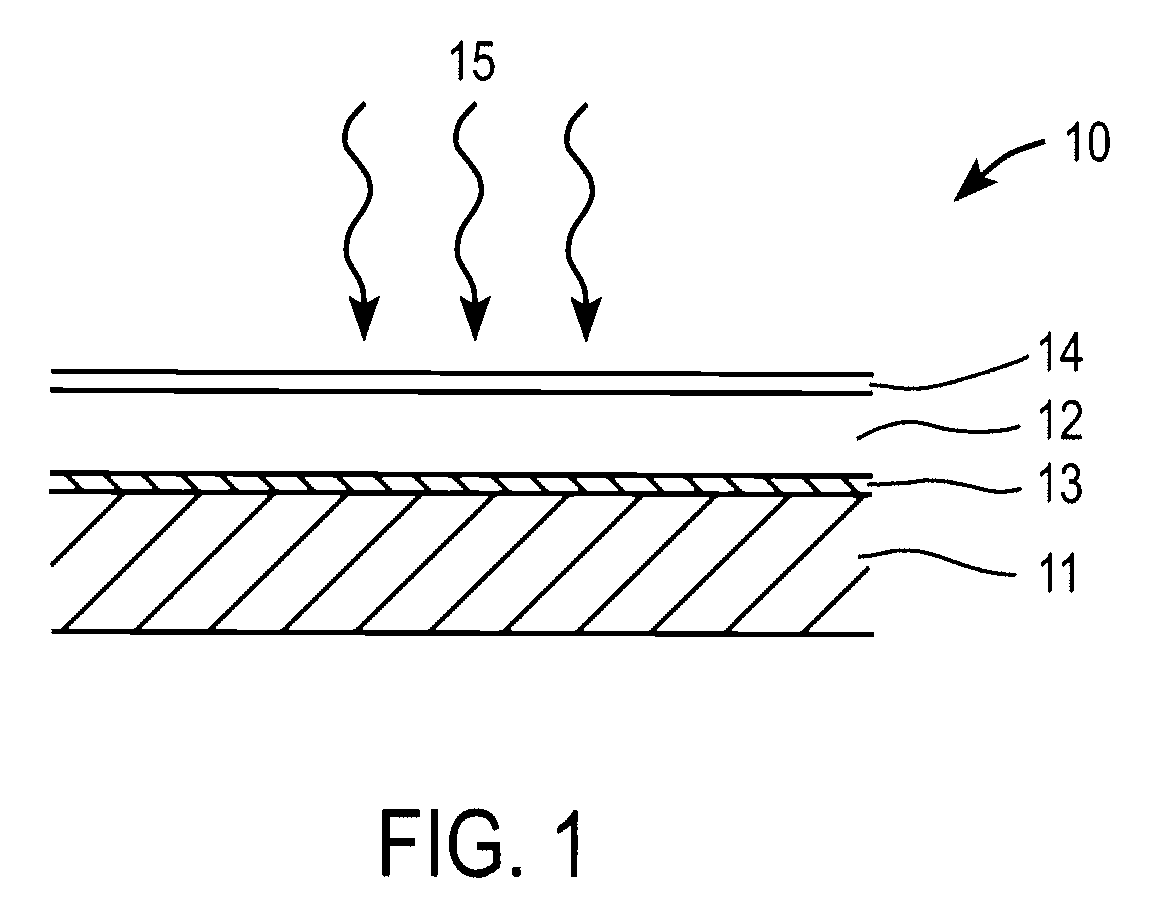

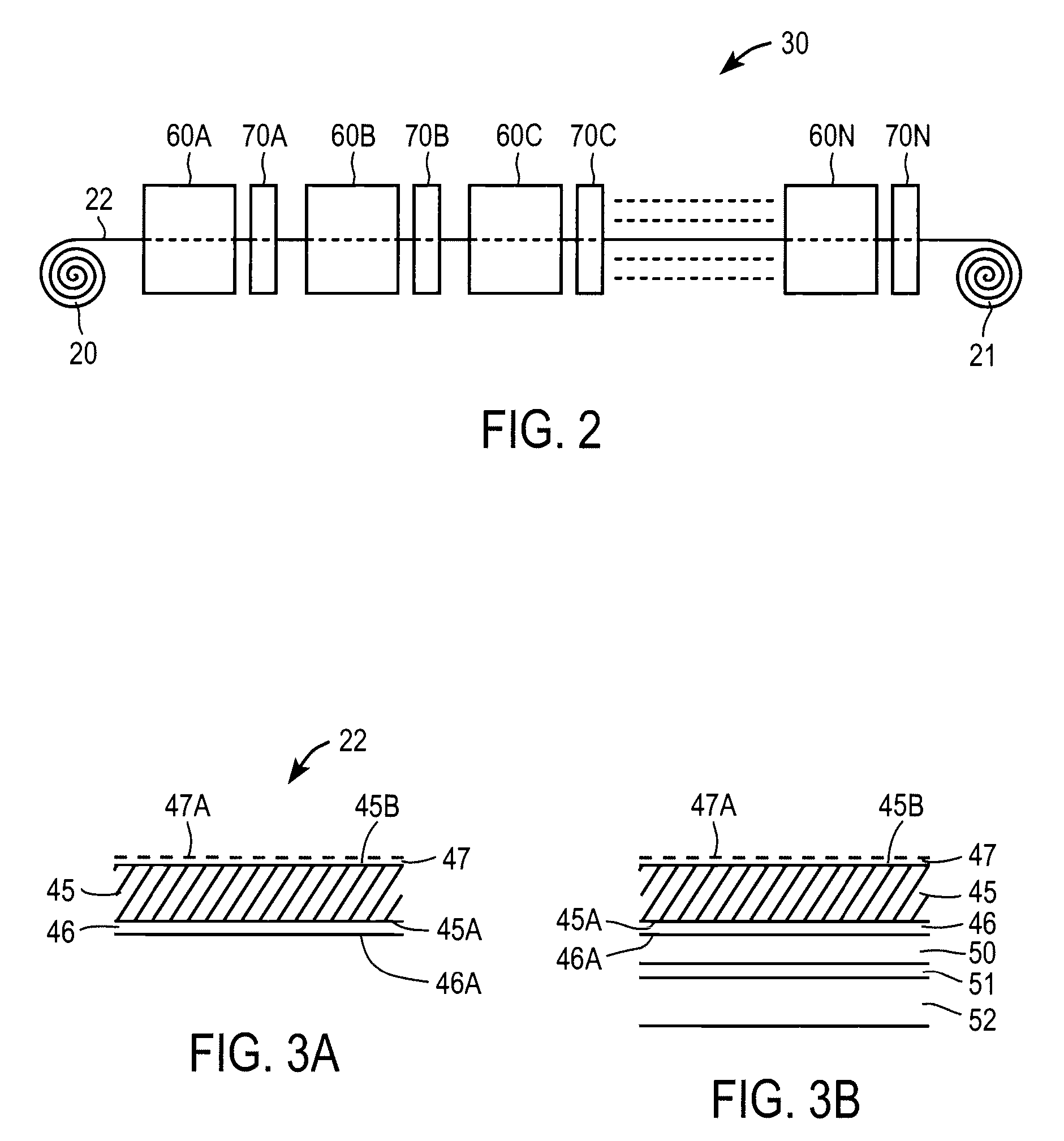

[0025]The present invention provides methods and apparatus to control the composition of precursor films or layers, which may be used in the formation of CIGS(S) type absorber layers, through an in-line or roll-to-roll manufacturing approach. The techniques may be used for the deposition of Group IB and Group IIIA materials and optionally Group VIA materials on a base to form precursor layers which are then converted into Group IBIIIAVIA compound layers by annealing at elevated temperatures, preferably in presence of additional Group VIA material(s). Deposition of Group IB, Group IIIA and Group VIA materials may be performed by various techniques such as evaporation, sputtering, spraying. doctor blading, printing, electrodeposition etc., and the processing system may be an in-line-system or a roll-to-roll system wherein layers or sub-layers of Group IB-containing, Group IIIA-containing and Group VIA-containing materials are deposited onto the base consecutively, one after another, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com