Etching composition and etching process

a technology of applied in the field of etching composition and etching process, can solve the problems of insufficient accuracy, difficult control of etching, excessively great etching rate, etc., and achieve the effect of suppressing the change in etching properties

Inactive Publication Date: 2007-12-06

MITSUBISHI GAS CHEM CO INC

View PDF6 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

An excessively great etching rate is not preferable since the control of the etching becomes difficult.

It is described that etching can be conducted with excellent accuracy without formation of residues by the etching using hydrochloric acid or nitric acid as an acidic solution of 0.005 to 0.2 N. However, when the above etching composition is actually used, the accuracy is insufficient due to a great amount of the side etching, and residues are formed.

Moreover, the etching rate changes to a great degree due to the change in the concentration of the acid caused by vaporization of water and dissolution of zinc during the etching, and the stable etching cannot be expected.

Although the etching of a zinc oxide film with an aqueous solution of acetic acid can be conducted, this process is not preferable due to the formation of residues.

Even when a polysulfonic acid compound is added to the aqueous solution of oxalic acid, crystals of zinc oxalate cannot be removed by etching.

However, etching residues are formed, and this process cannot be used.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

examples

[0045] The present invention will be described more specifically with reference to Examples and Comparative Examples in the following. However, the present invention is not limited to the examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Login to View More

Abstract

An etching composition which comprises at least one organic carboxylic acid compound selected from acetic acid, propionic acid, butyric acid, succinic acid, citric acid, lactic acid, malic acid, tartaric acid, malonic acid, maleic acid, glutaric acid, aconitic acid, 1,2,3-propanetricarboxylic acid and ammonium salts of these acids, a polysulfonic acid compound and water, and an etching process which comprises etching a conductive film comprising zinc oxide as the main component using the etching composition described above.

Description

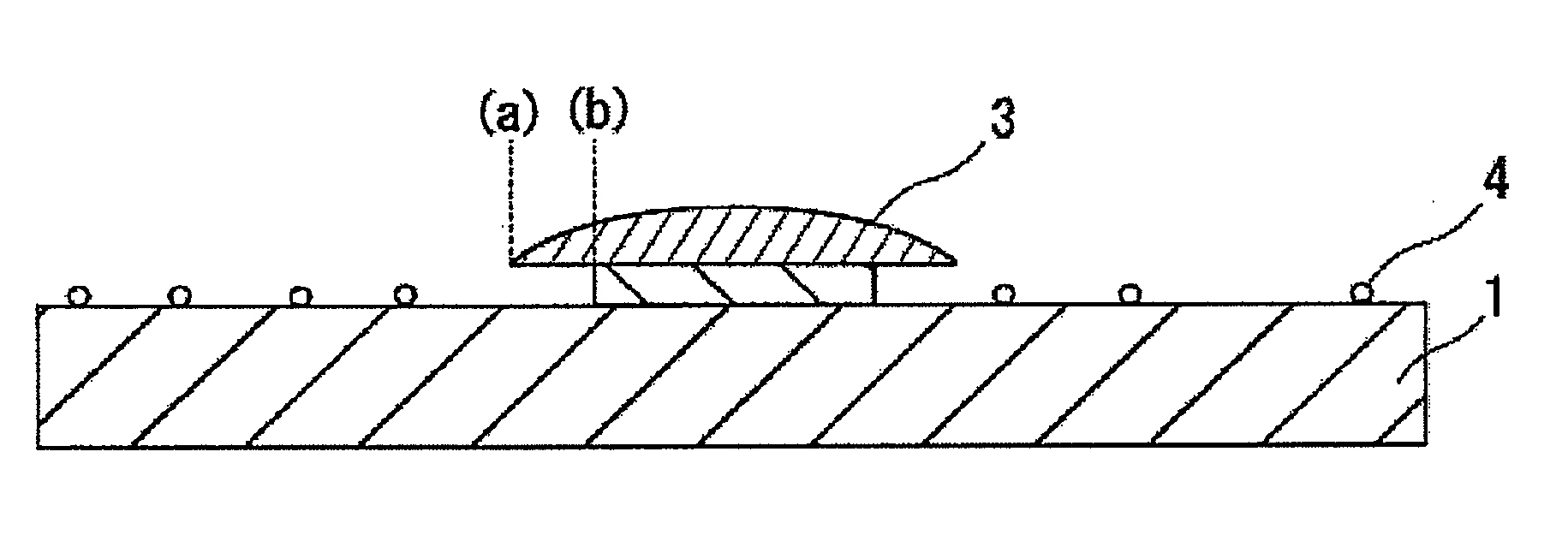

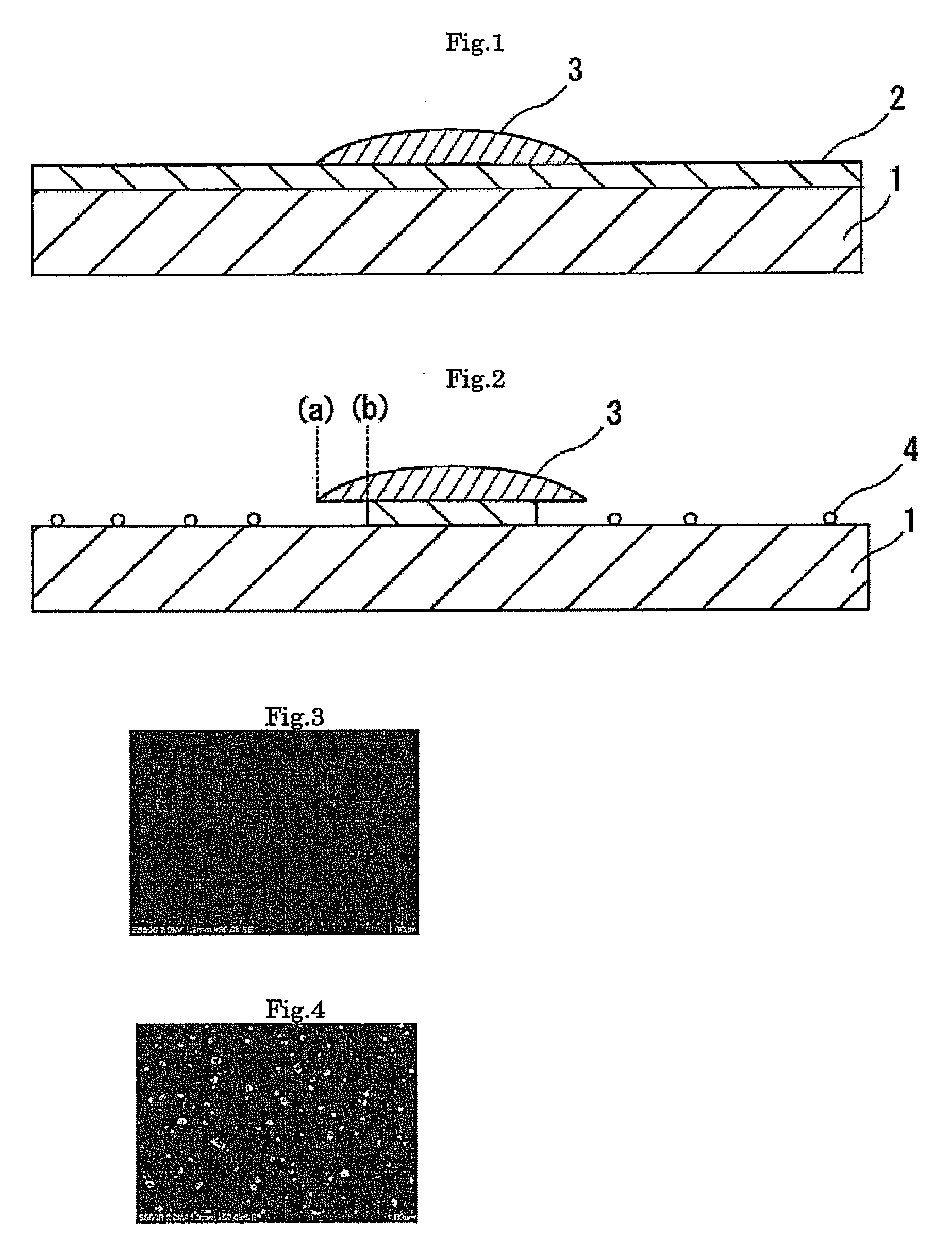

BACKGROUND OF THE INVENTION [0001] 1. Field of the Invention [0002] The present invention relates to an etching composition used for etching conductive films which comprises zinc oxide as the main component and are used for display devices such as liquid crystal displays (LCD) and electroluminescence displays and to an etching process using the etching composition. [0003] 2. Description of the Related Art [0004] As the conductive film for display devices such as liquid crystal displays and electroluminescence displays, films of indium tin oxide (ITO) and films of indium zinc oxide (IZO) are widely used. Due to the decrease in the resources for indium, electrically conductive materials which can be used in place of ITO and IZO have been developed. [0005] Conductive films containing zinc oxide as the main component are widely used as the Piezoelectric thin films, optical waveguide films and gas sensitive films and are expected as the material which can be used in place of conventional...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(United States)

IPC IPC(8): C03C15/00C09K13/00

CPCC09K13/00C09K13/06

Inventor MATSUBARA, MASAHIDEMARUYAMA, TAKETO

Owner MITSUBISHI GAS CHEM CO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com