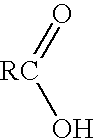

Polymeric Polyol Esters Used in Metalworking Fluids

a technology of polyol esters and metalworking fluids, applied in the direction of liquid carbonaceous fuels, lubricant compositions, fuels, etc., to achieve the effects of enhancing solubility, reducing acid numbers, and improving solubility characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific embodiment

[0032]The following example(s) demonstrate the present invention:

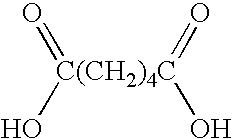

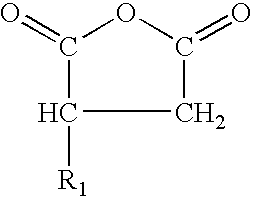

Example of Polymeric Polyol Ester

[0033]A glass reactor equipped with a stirrer, thermometer, nitrogen inlet and water-trap connected to a condenser was charged with about 8.0 equivalents coconut fatty acid, about 2.4 equivalents 1000 Mn polyisobutylene succinic anhydride, about 8.3 equivalents monopentaerythritol, about 8.3 equivalents trimethylolpropane, about 5.8 equivalents adipic acid, and about 0.1 wt % of hypo phosphorous acid. The reaction mixture was heated to about 180° C. for about 2 hours while removing water of reaction. After holding for about 2 hours, the reaction temperature was increased to about 240 to 245° C. and maintained at that temperature while removing water of reaction until the total acid number was less than about 5 mg KOH / g and the kinematic viscosity @100° C. was between about 250 to 400 cSt. (total reaction time is typically 16 to 24 hours).

[0034]To verify the above polymeric polyol ester ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com