Apparatus for cleaning a substrate having metal interconnects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

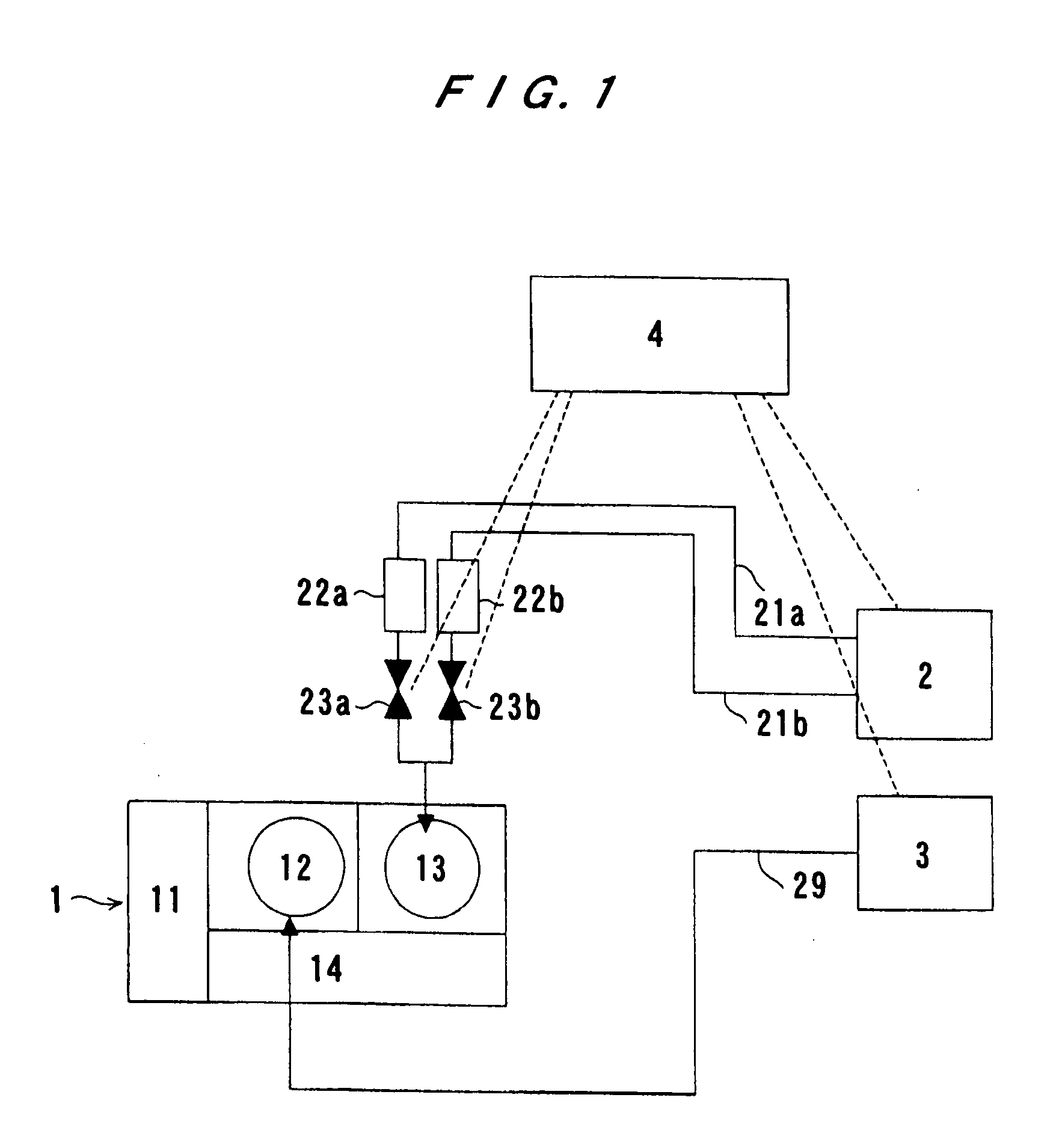

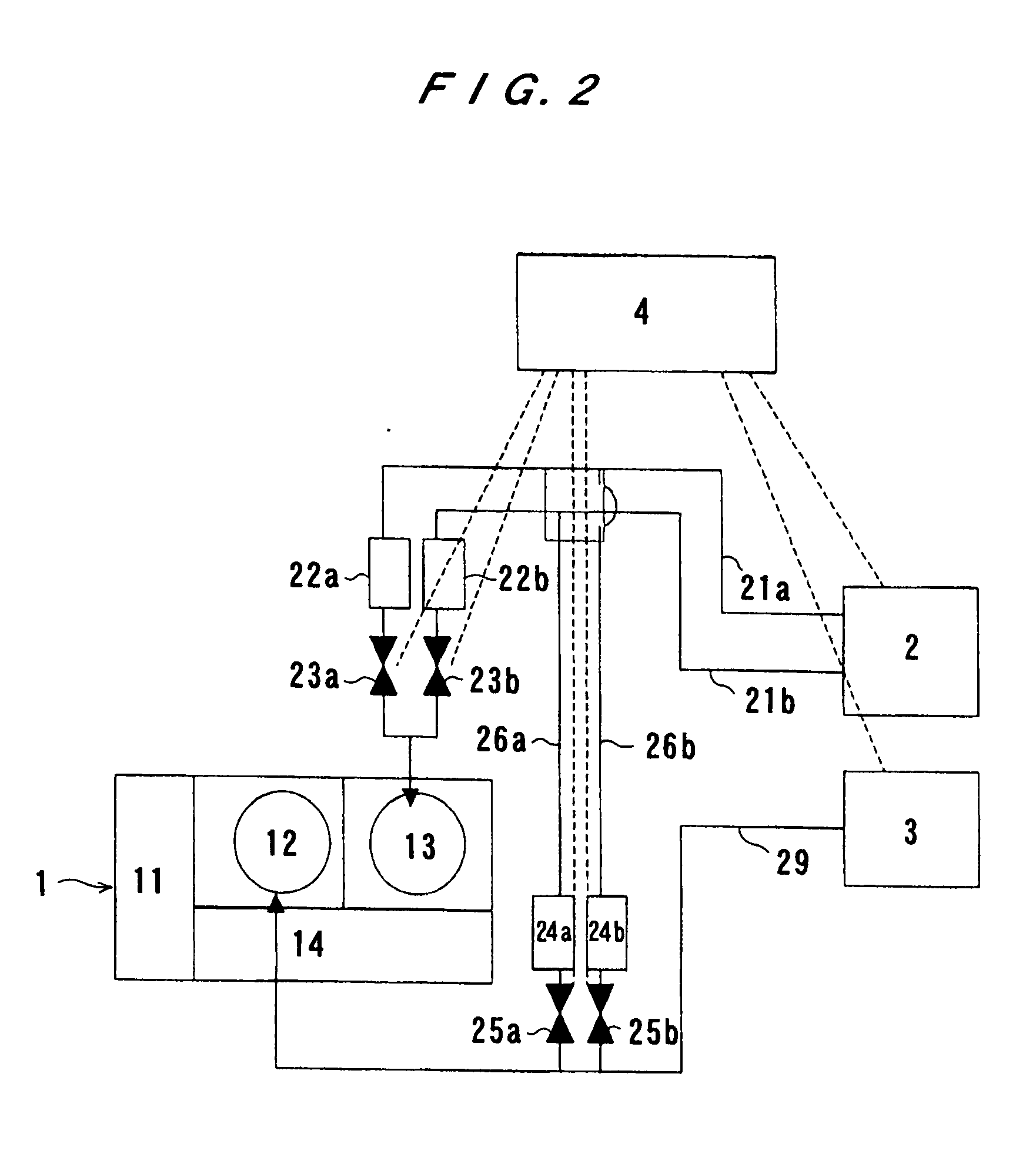

[0043]FIG. 1 is a schematic view showing a basic structure of a cleaning apparatus according to the present invention. As shown in FIG. 1, a cleaning apparatus comprises a cleaning unit 1 serving as a cleaning mechanism, a functional water producing unit 2 serving as a functional water supply mechanism, a chemical liquid supply unit 3, a controller 4, a pair of functional water supply pipes 21a, 21b, a pair of flow meters 22a, 22b, a pair of valves 23a, 23b, and a chemical liquid supply pipe 29. The cleaning unit 1 comprises a loading / unloading unit 11, a chemical processing module 12, a cleaning / drying module 13, and a transfer module 14.

[0044] A substrate to be cleaned is introduced into the cleaning unit 1 through the loading / unloading unit 11. The substrate is processed, e.g. etched, in the chemical processing module 12, and is then cleaned and dried in the cleaning / drying module 13. The substrate which has been cleaned and dried is transferred to a subsequent process by the tra...

second embodiment

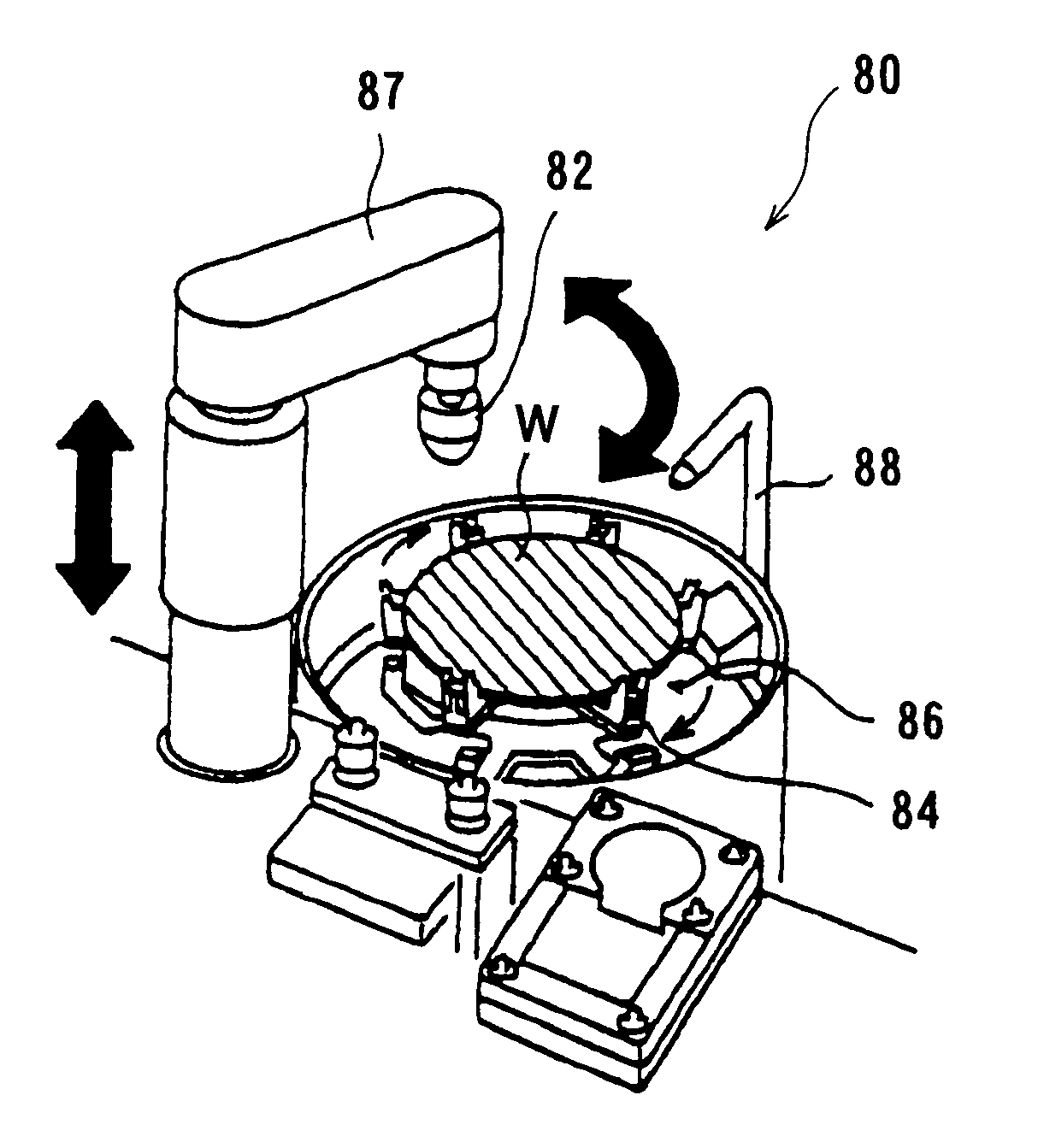

[0066]FIG. 7 is a schematic view showing an example of a cleaning / drying module incorporated in the cleaning apparatus according to the first or second embodiment of the present invention. A cleaning / drying module 70 shown in FIG. 7 performs a roll cleaning process while holding and rotating a substrate having interconnects. As shown in FIG. 7, the cleaning / drying module 70 comprises a plurality of rollers 73a, 73b for holding and rotating a substrate W, a plurality of roll-shaped cleaning members 74a, 74b for cleaning the substrate W, functional water supply nozzles 75a, 75b for supplying functional water to the substrate W, and chemical liquid supply nozzles 76a, 76b for supplying a chemical liquid such as an etching liquid or a chemical cleaning liquid to the substrate W. The rollers 73a, 73b hold a circumferential edge of the substrate W and rotate the substrate W about its own axis in a horizontal plan. The roll-shaped cleaning members 74a, 74b are brought into contact with an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electric potential / voltage | aaaaa | aaaaa |

| Electric potential / voltage | aaaaa | aaaaa |

| Electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap