Method for Increasing Catalyst Temperature Using Ethanol-Blended Diesel Fuels

a technology of ethanol-blended diesel fuel and catalyst temperature, which is applied in the direction of machines/engines, mechanical equipment, separation processes, etc., can solve the problems of low catalyst temperature, low catalyst temperature, and low catalyst temperature, so as to reduce the nox of diesel exhaust, reduce the effect of noise and distinctive odor, and maximize fuel economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

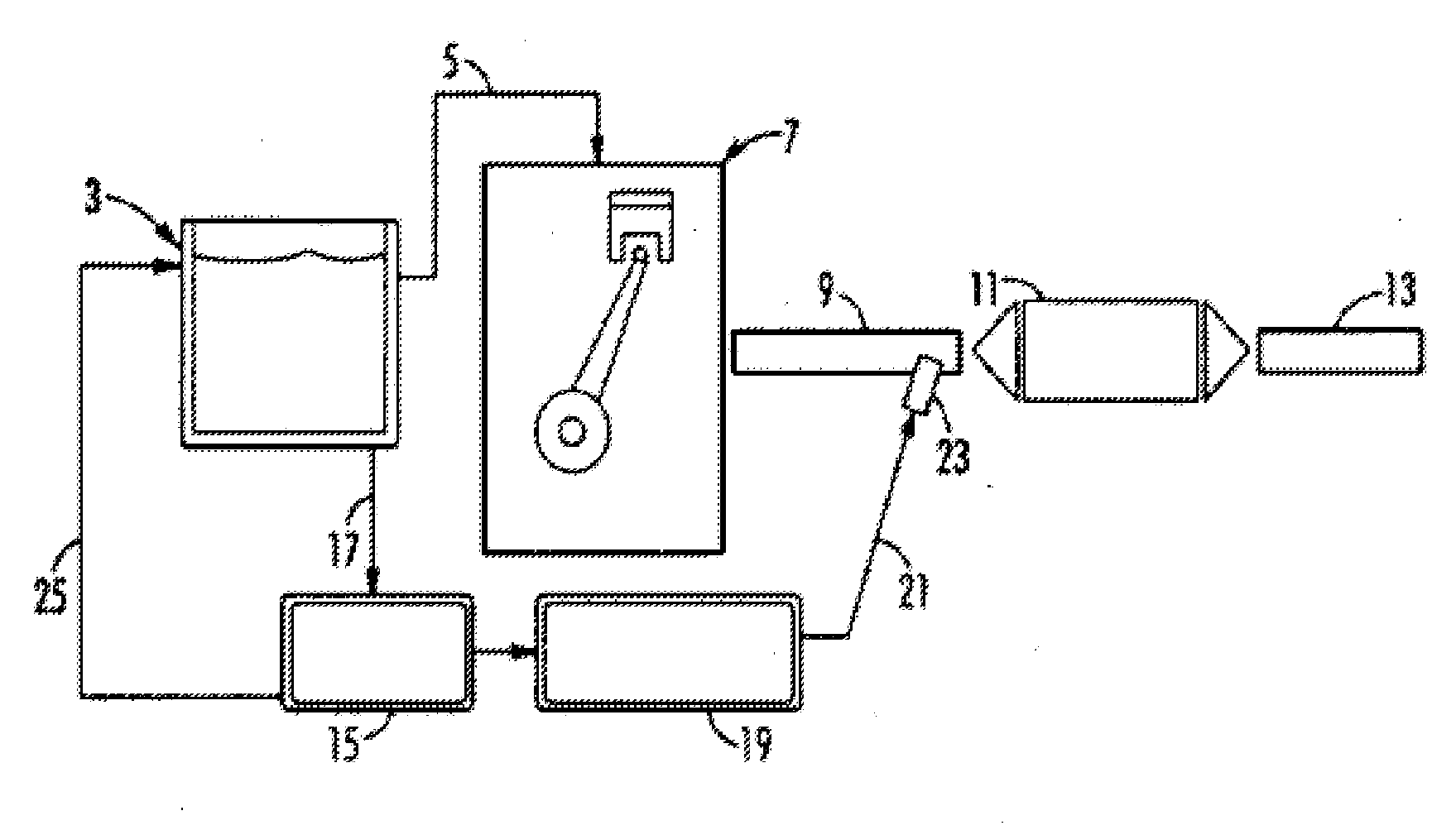

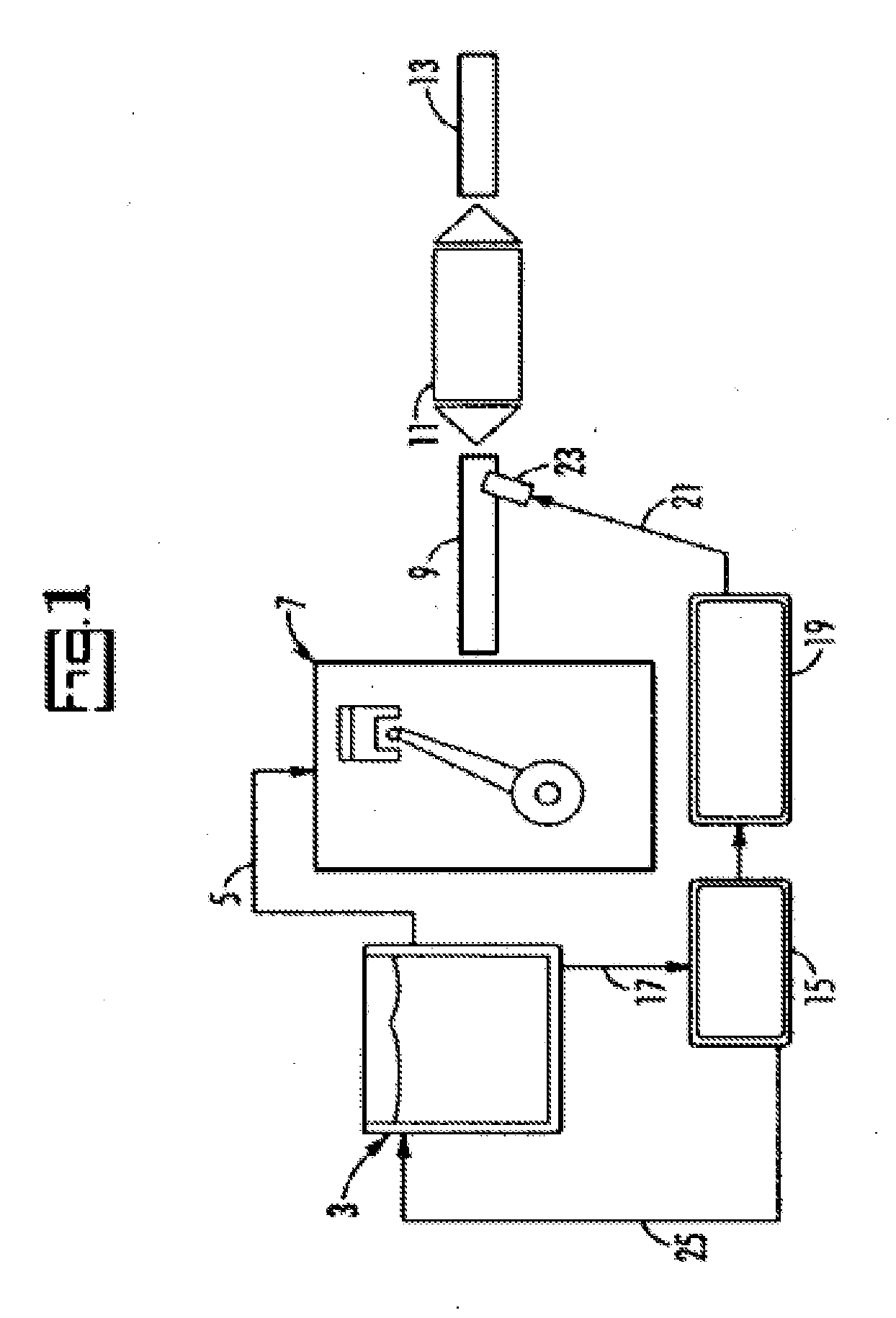

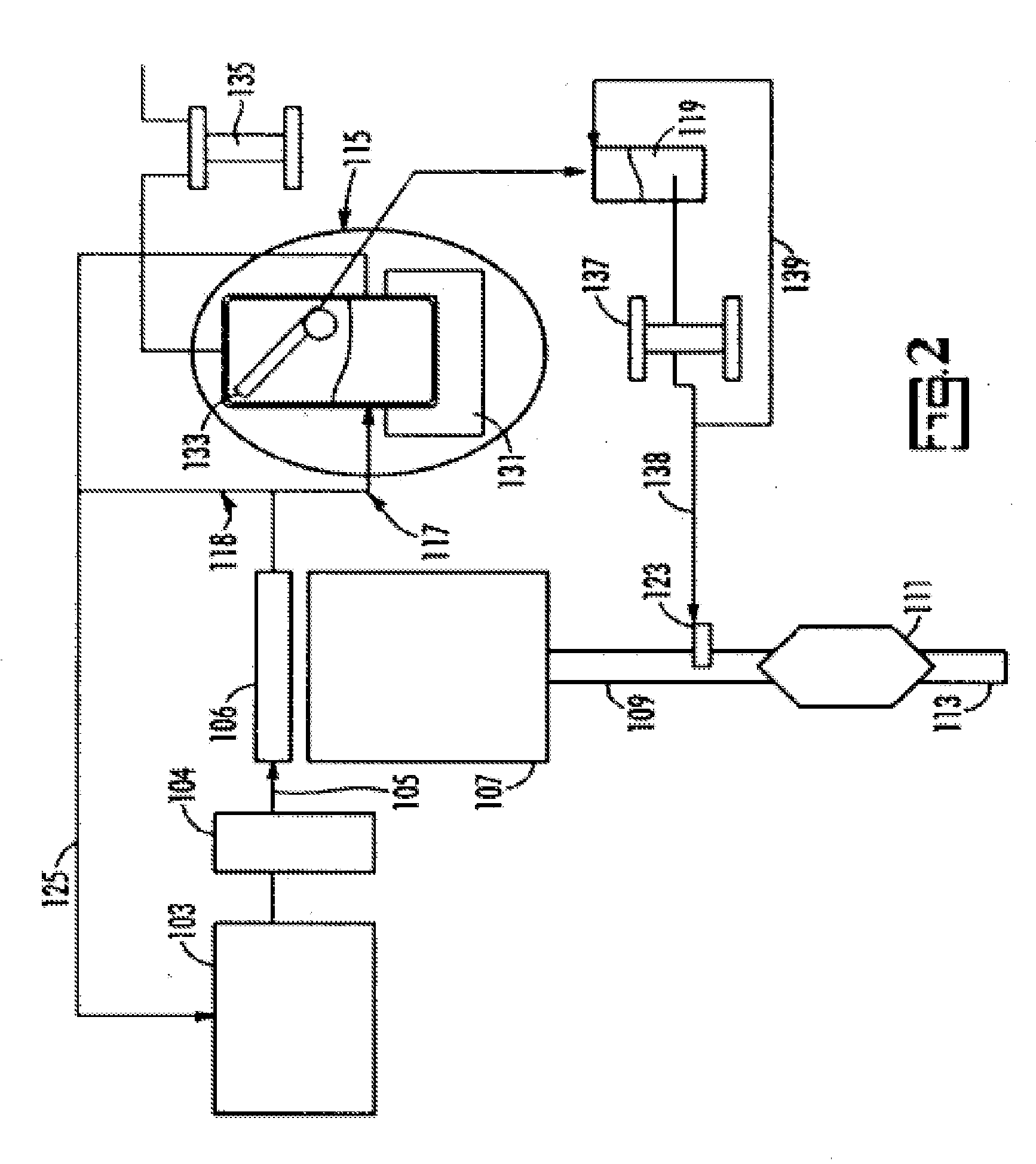

Image

Examples

Embodiment Construction

[0023] Commercial E-diesel such as that available fro Pure Energy Corporation contains approximately 15% ethanol, 1.5% a “proprietary additive” designed to stabilized the fuel and 80-84% low sulphur No. 2 diesel. ASTM standard D975 specifies minimum standards for “diesel fuel,” including boiling point ranges. Accordingly to the standard for low sulphur No. 2, 90% of the fuel must distill between 282 and 338° C. Typically, the majority boils between 250 and 300° C. Ethanol boils at 78.5° C. at 760 mmHg. It has been found by experiment that 90% of the included ethanol can be stripped at a temperature of 80° C. This final product contains 95% by volume ethanol and 5% by volume hydrocarbon components. Since both ethanol and light hydrocarbons are effective reductants using available SCR catalysts, the stripped mixture need not be chemically pure to reduce NOx.

[0024] Suitable selective catalyst reducing (SCR) materials suitable for use with ethanol include alumina-supported tin or tin o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com