Controlled flow polymer blends and products including the same

a technology of polymer blends and products, applied in the field of polymer blends and articles, can solve the problems of inadequate melt strength and limited usefulness of polymer blends, and achieve the effect of facilitating manufacturing and downstream storage and transportation of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1 (

INVENTION)

[0099]45% of a high molecular weight maleated polyethylene (such as that commercially available from Eastman Chemical as Epolene G-2608) is blended with 55% of a common paraffin (such as that commercially available as IGI 1230). The resulting blend exhibits sufficient melt strength for fiber spinning and further bonds (without pressure) to acrylic at 120° C., which is a 60° C. drop from the temperature required of G-2608 alone. The mixture does not exhibit blocking on the package even when held at temperatures above the melting point of the paraffin.

example 2 (

INVENTION)

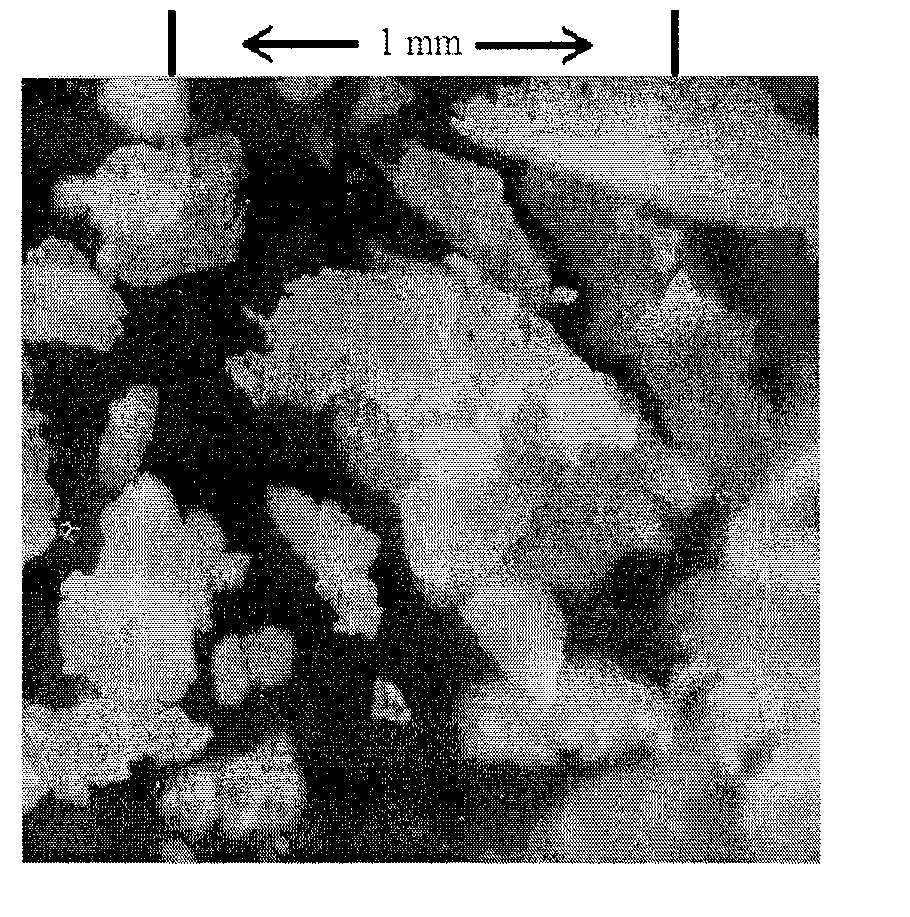

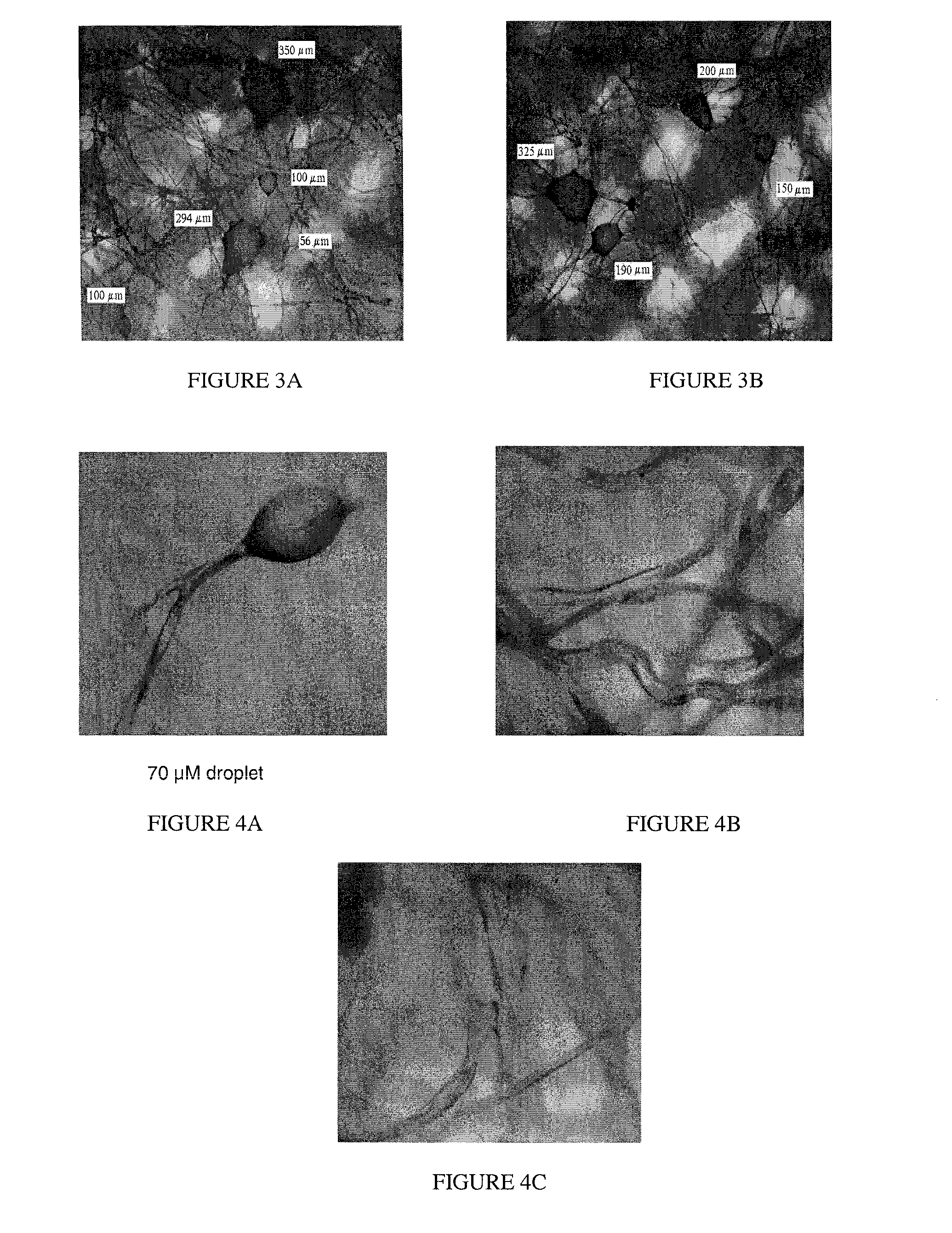

[0100]50% of a maleated polypropylene wax (such as Eastman's Epolene C-18) is blended with 50% of a common paraffin (IGI 1230). This material is coated onto acrylic yarn and incorporated into chenille yarn. The blend bonds in boiling water baths typical of dying processes, yet does not exhibit blocking problems upon shipping. Improved wear resistance of the chenille is achieved at normal use temperatures in such applications as automotive upholstery. This example exemplifies a “100° C. flow system” as discussed herein and is illustrated in FIGS. 1, 3A-B and 4A-C. In this example, the paraffin component alone exhibits blocking and no functionality for wet-out. The Epolene wax exhibits too high a melting point to flow at the desired temperatures. The blend can be useful as a coating onto a yarn and as a core of a chenille yarn. The blend can penetrate readily into an effect yarn (such as an acrylic or cotton effect yarn) at about 100° C. (a temperature sufficient to drive of...

example 3 (

INVENTION)

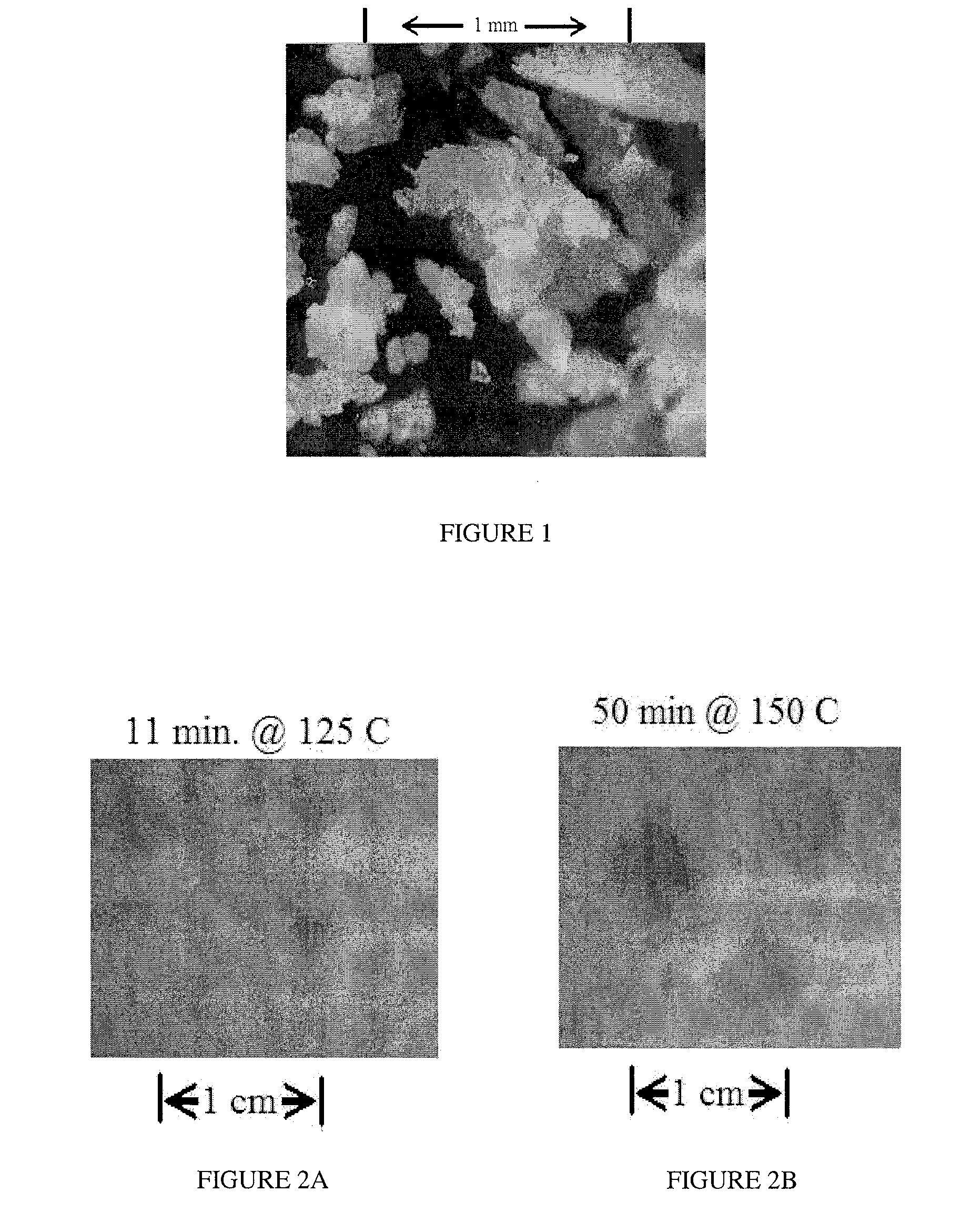

[0101]A low molecular weight maleated polyethylene or polypropylene wax, such as those commercially available from Eastman Chemical under the trade name Epolene, is blended with a high molecular weight polyethylene or modified polypropylene to gives results similar to that exhibited by the blend of Example 2. The blend exhibits high flow yet good fiber-forming properties at remarkably low temperatures, and at the same time good integrity in uncontrolled storage conditions. This example exemplifies a “150° C. flow system” as discussed herein and is illustrated in FIGS. 2A and 2B. In this example, the polyethylene alone exhibits poor flow at this temperature and no functionality. The Epolene wax has too low a viscosity / melt strength to be spun into fibers. The blend may be useful spun as the sheath of a bicomponent filaments yarn and the yarn can be used as the core of a chenille yarn, When heated in an autoclave, the bonder can readily penetrate into the effect yarn and hol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com