Onboard fuel cell system and method of discharging hydrogen-off gas

a fuel cell and fuel cell technology, applied in the field of onboard fuel cell systems and methods of discharging hydrogenoff gas, can solve the problems of hydrogen-off gas catching fire and not much attention, and achieve the effect of reducing the concentration of hydrogen smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

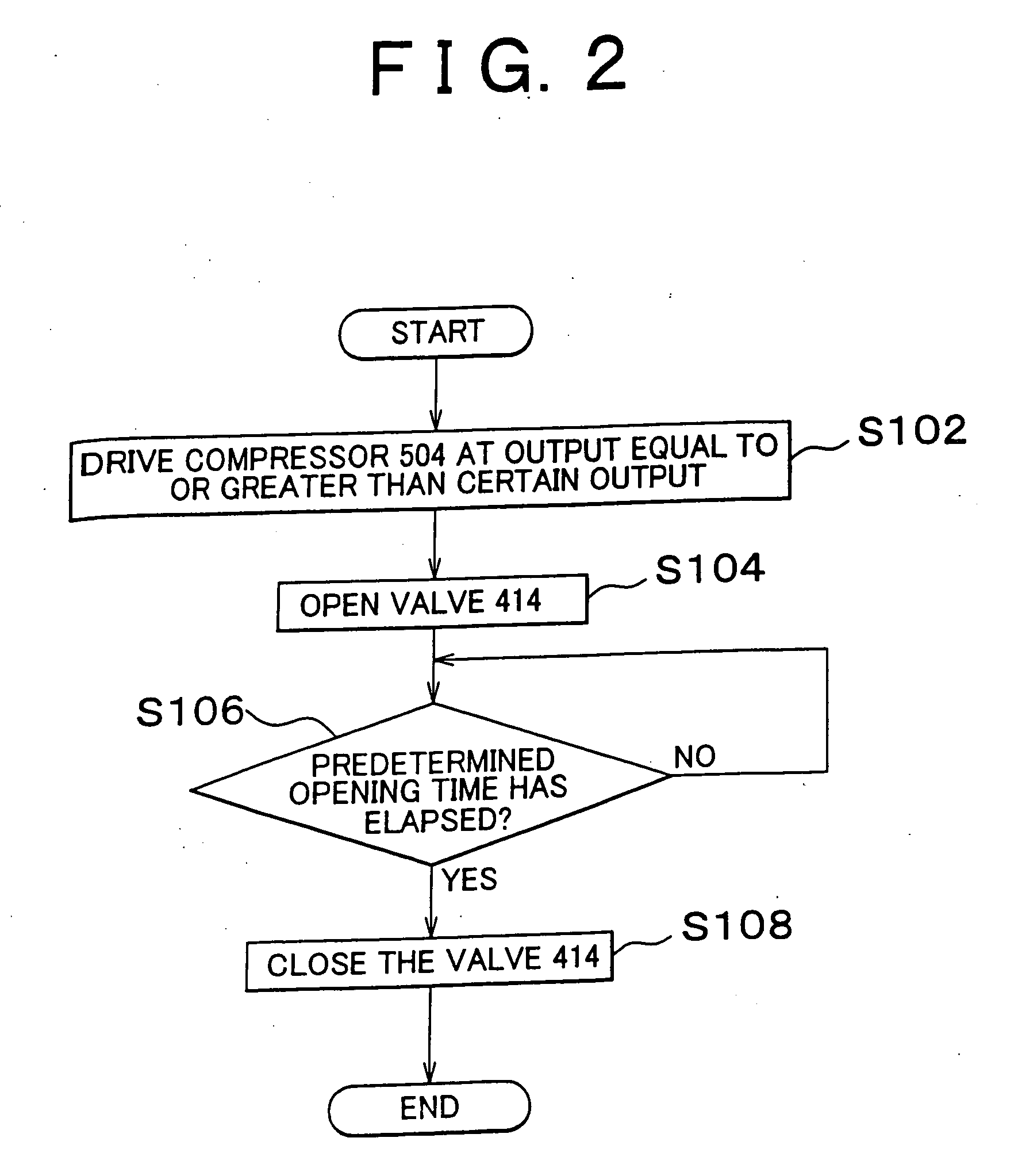

first embodiment

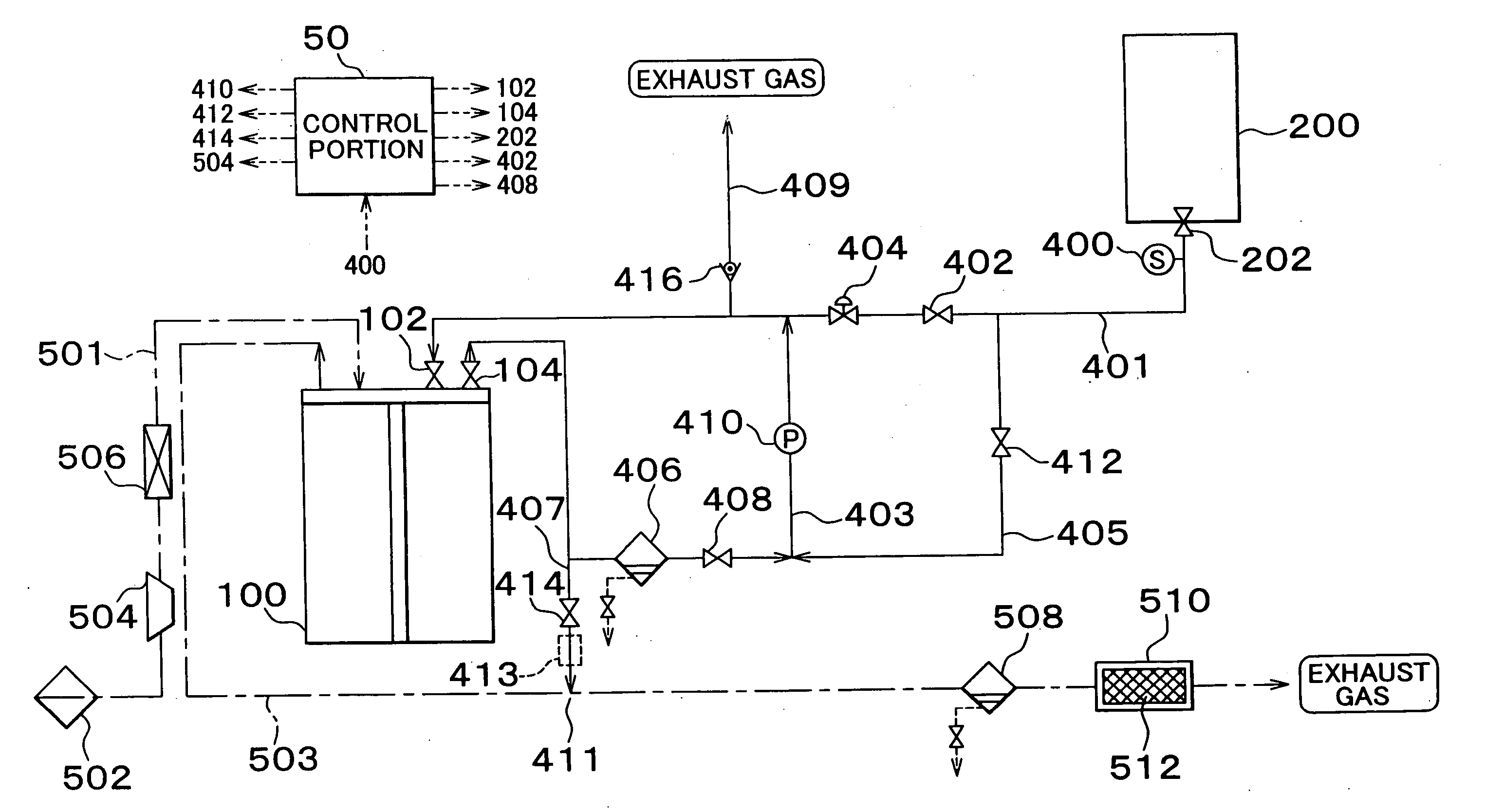

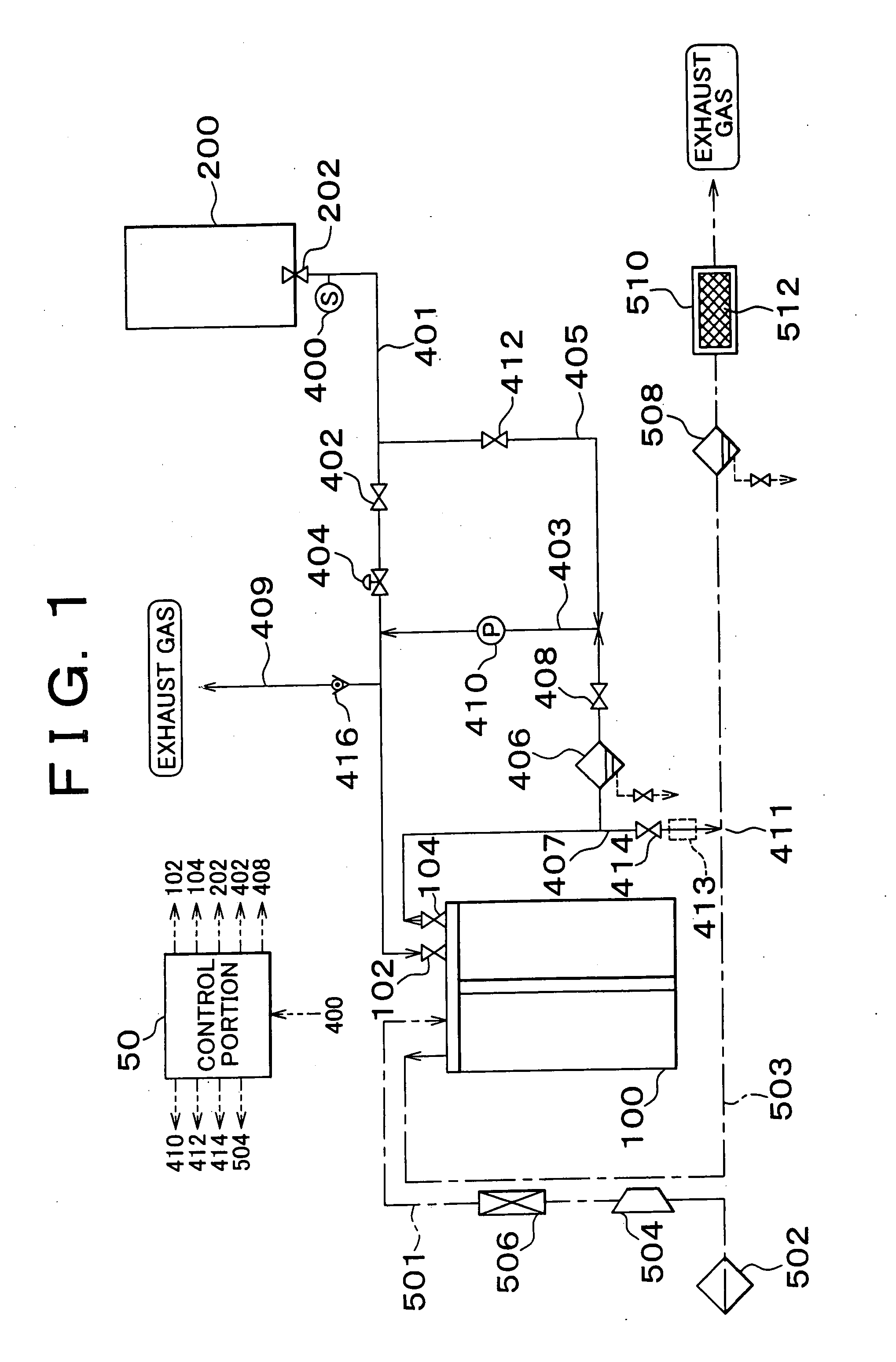

[0029]FIG. 1 is a block diagram of an onboard fuel cell system according to the invention. The fuel cell system of this embodiment is designed to be installed in a vehicle such as an automobile or the like, and is mainly composed of a fuel cell 100 and a hydrogen-occluding alloy tank 200. The fuel cell 100 is supplied with hydrogen gas and generates electric power. The hydrogen-occluding alloy tank 200 supplies the fuel cell 100 with hydrogen gas.

[0030] The fuel cell 100 is supplied with oxidative gas containing oxygen (e.g., air) as well as hydrogen gas containing hydrogen, causes electrochemical reactions in its anode (hydrogen pole) and cathode (oxygen pole) according to reaction formulae shown below, and generates electric power.

[0031] That is, if the anode and the cathode are supplied with hydrogen gas and oxidative gas respectively, the reactions according to the formulae (1) and (2) occur on the anode side and the cathode side respectively. As a whole, the reaction according...

third embodiment

[0096] In the fuel cell system of the third embodiment, as shown in FIG. 7, the hydrogen gas flow passage and the oxidative gas flow passage of the fuel cell system are partially different in construction from those of the aforementioned embodiments.

[0097] As in the case of the aforementioned embodiments, the hydrogen gas flow passage has the main flow passage 401 extending from the high-pressure hydrogen gas tank 300 to the fuel cell 100, the circulation flow passage 403 of the fuel cell 100, the exhaust flow passage 407 designed to discharge impurities, and the relief flow passage 409 designed to discharge hydrogen gas at the time of application of an abnormal pressure. In addition, the hydrogen gas flow passage of this embodiment has another relief flow passage 430, a leak check flow passage 427, and a supply flow passage 432. The relief flow passage 430 is designed to enhance the reliability in discharging hydrogen gas at the time of application of an abnormal pressure. The leak...

second embodiment

[0098] In addition to the shut valve 302 disposed at the discharge port of the high-pressure hydrogen gas tank 300, the main flow passage 401 has a discharge manual valve 304, the pressure-reducing valve 418, a heat exchanger 420, and the pressure-reducing valve 422. As in the case of the second embodiment, the circulation flow passage 403 is provided with the gas-liquid separator 406 and the like and causes hydrogen-off gas to circulate through the check valve 426 by means of the pump 410. A check valve 306 and a filling manual valve 308 are disposed in the supply flow passage 432 at the filling port of the high-pressure hydrogen gas tank 300. The exhaust flow passage 407 has the shut valve 414 and a hydrogen diluter 424. The relief flow passages 430, 409 have a relief valve 415 and the relief valve 416 respectively. The leak check flow passage 427 has a leak check port 428.

[0099] As in the aforementioned embodiments, the oxidative gas flow passage has the oxidative gas-supplying f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| opening time | aaaaa | aaaaa |

| opening time | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com